Process extracting purified danshen extract from red sage root

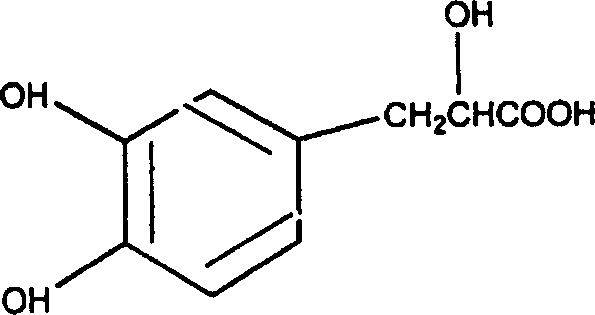

A technology of Danshensu and Danshen, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problem of low production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1.5 kg of traditional Chinese medicine Salvia miltiorrhiza is extracted with 15 kg of water, and the extract flows through an adsorption column filled with 200 ml of strong basic resin 717 for adsorption. The diameter of the adsorption column is 30 mm, and the flow rate is 10 times the resin volume per hour. After the extract has flowed out, use 400 ml of 4% sodium hydroxide eluent to elute at a rate of 2 times the volume of the resin per hour to obtain 420 ml of eluate, adjust the pH of the eluent to 5 and then add 850 ml Ethyl acetate is used for extraction, and then the organic solvent containing danshensu is vacuum-concentrated to recover the solvent to obtain 13 grams of danshensu product, containing 31% of danshensu.

Embodiment 2

[0023] After 5 kilograms of Chinese medicine salvia miltiorrhiza was extracted with 50 kilograms of water, the extract flowed through an adsorption column (80 millimeters in diameter) filled with 2000 milliliters of HZ802 adsorption resin and an adsorption column (30 millimeters in diameter) filled with 400 milliliters of 717 ion exchange resin respectively. The flow rate is 4 liters per hour. After the extract has flowed out, use 3000 ml of 1% sodium hydroxide eluent to elute the HZ802 adsorbent at a rate of 2 times the volume of the resin per hour. Use 800 milliliters of 10% sodium chloride to elute the 717 resin at a rate of 2 times the resin volume per hour to obtain 850 milliliters of eluent. After adjusting the pH of this eluent to 3, add 1800 milliliters of ethyl acetate for extraction. Then the ethyl acetate solution containing danshensu was vacuum concentrated and crystallized to obtain 28 grams of danshensu product, containing 52% of danshensu.

Embodiment 3

[0025] After 5 kg of traditional Chinese medicine Salvia miltiorrhiza was extracted with 50 kg of water, the extract flowed through an adsorption column (80 mm in diameter) filled with 2000 ml of HZ802 adsorption resin and an adsorption column (30 mm in diameter) filled with 400 ml of D201×2 ion exchange resin respectively. ) at a flow rate of 4 liters per hour. After the extract has flowed out, use 3000 ml of 1% sodium hydroxide eluent to elute the HZ802 adsorbent at a rate of 2 times the volume of the resin per hour. Use 800 milliliters of 10% sodium chloride to elute the D201×2 resin at a rate of 2 times the volume of the resin per hour to obtain 880 milliliters of eluent. After adjusting the pH of this eluent to 3, add 2000 milliliters of ether for extraction. Then the ether solution containing danshensu is vacuum concentrated and crystallized to obtain 12 grams of danshensu product, containing 91% of danshensu.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com