Improved string cutter for sewing machine

A sewing machine and thread cutting technology, which is applied to sewing equipment, sewing machine components, and thread cutting mechanisms in sewing machines, etc., can solve problems such as affecting hook rods and cutting, inability to effectively fine-tune the position or swing amplitude, and great frustration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

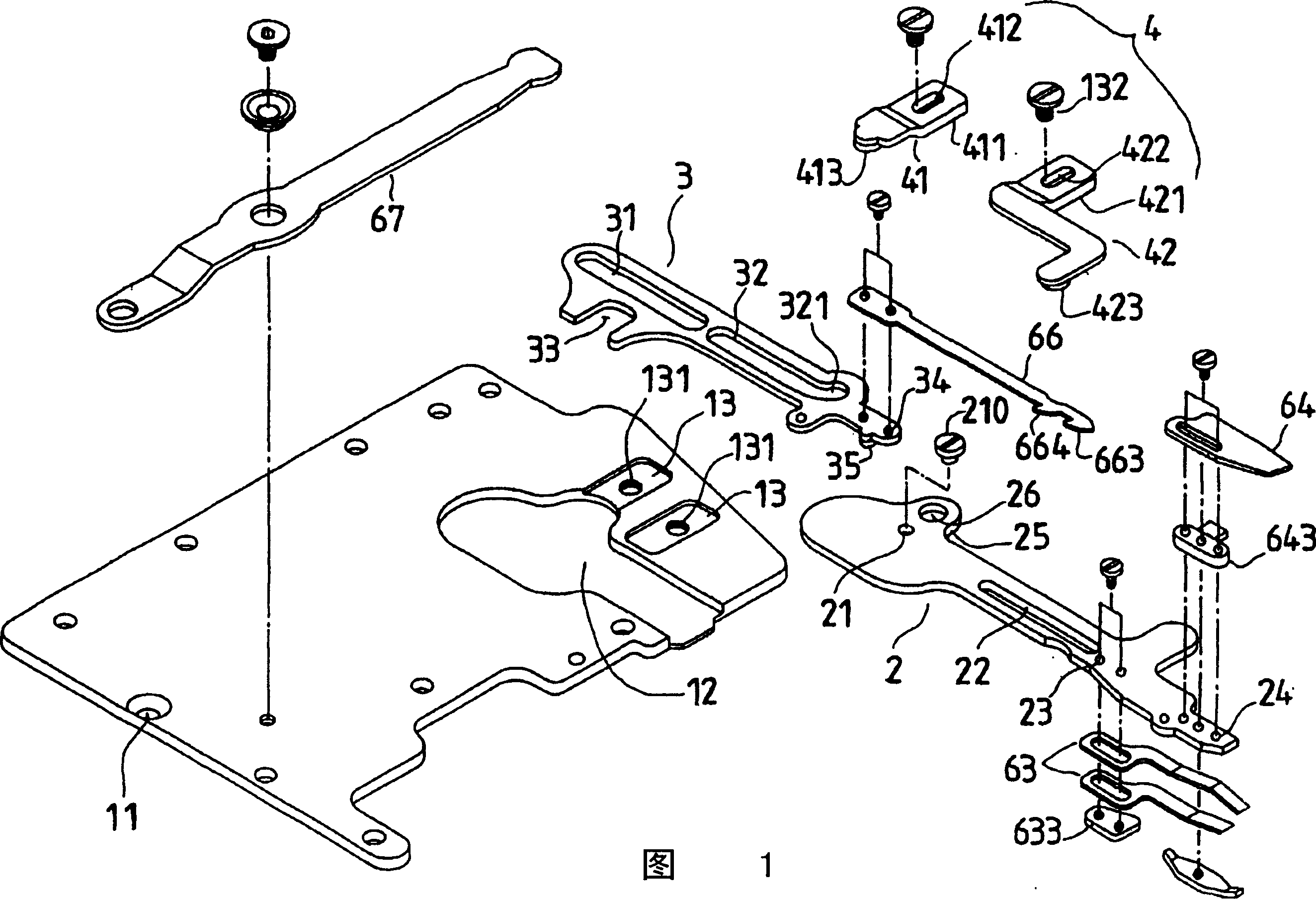

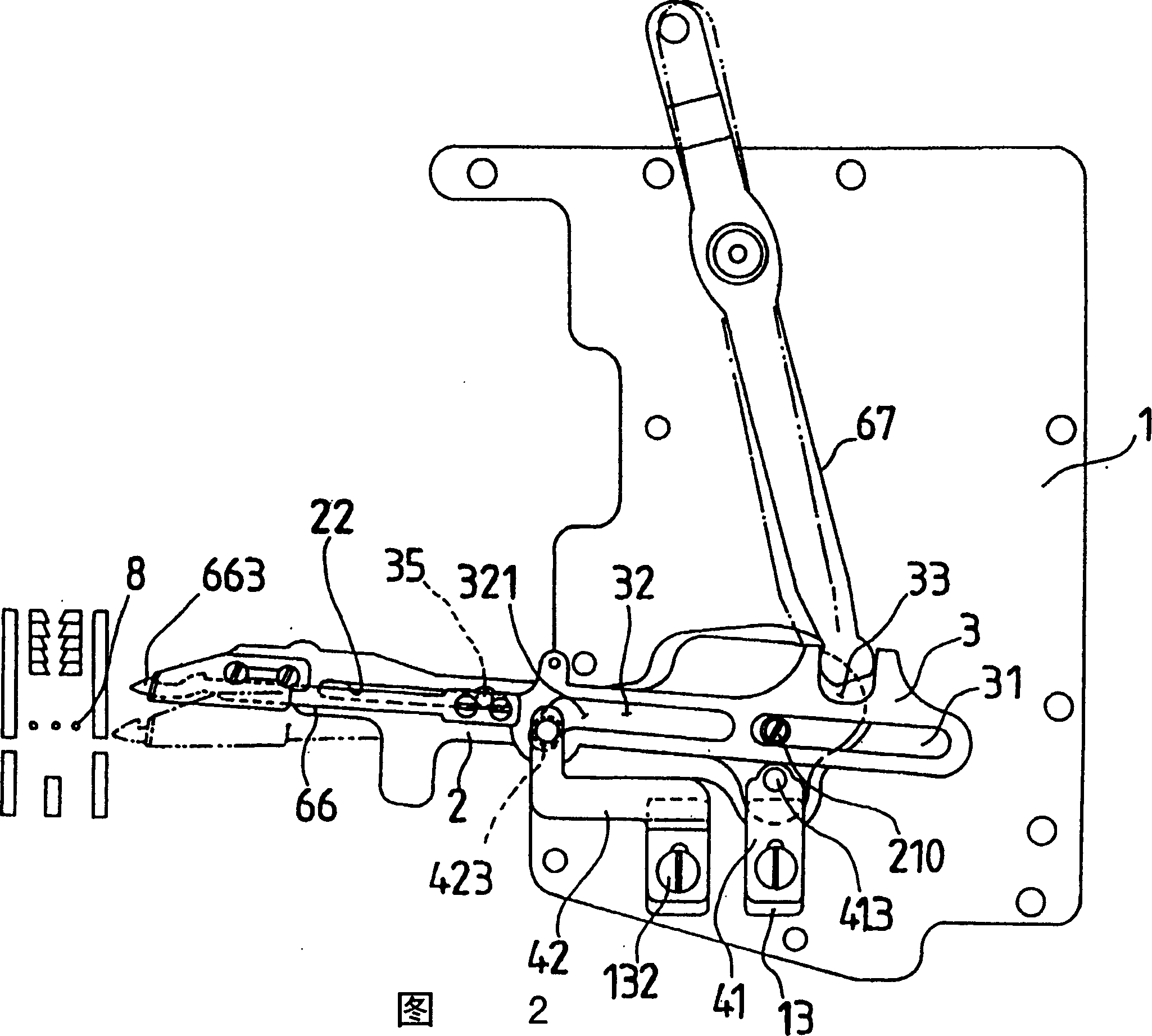

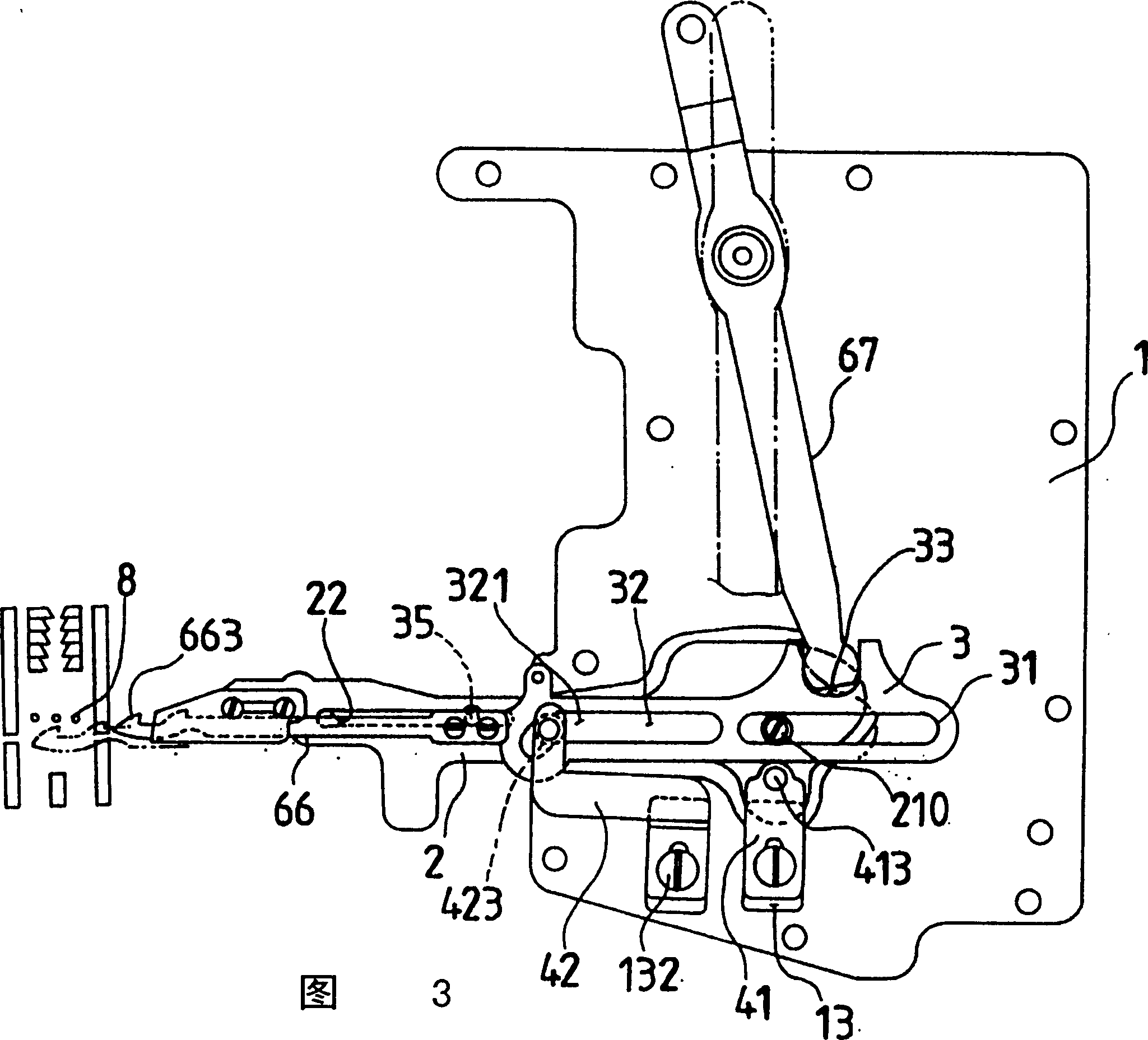

[0035] First of all, please refer to FIG. 1 , the present invention is composed of a plate body 1 , a cutter arm 2 , a hook arm 3 and a cantilever group 4 in combination with a commonly used clip 63 , a cutter 64 , a hook rod 66 and a swing arm 67 . .

[0036] Please refer to FIGS. 1 to 5 together. There are several positioning holes 11 on the periphery of the board body 1 , and a configuration slot 12 and two positioning sliding grooves 13 are formed therein. The two positioning sliding grooves 13 both have screw holes 131 for the screws 132 to pass through. After passing the cantilever group 4, it is screwed.

[0037] One end of the cutter arm 2 can be placed in the configuration slot 12, and a hole 21 is provided for assembling the protruding post 210, the other end is provided with an elongated hole 22, and the rear end is respectively provided with a hole 23 and a screw hole 24 for A clip 63 and a cutter 64 are assembled. The right side of the hole 21 is additionally pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com