Battery separator with improved shoulders

A battery separator and flank area technology, which is applied in battery pack components, separators/films/diaphragms/spacers, circuits, etc., can solve problems such as puncture in the flank areas of the separators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

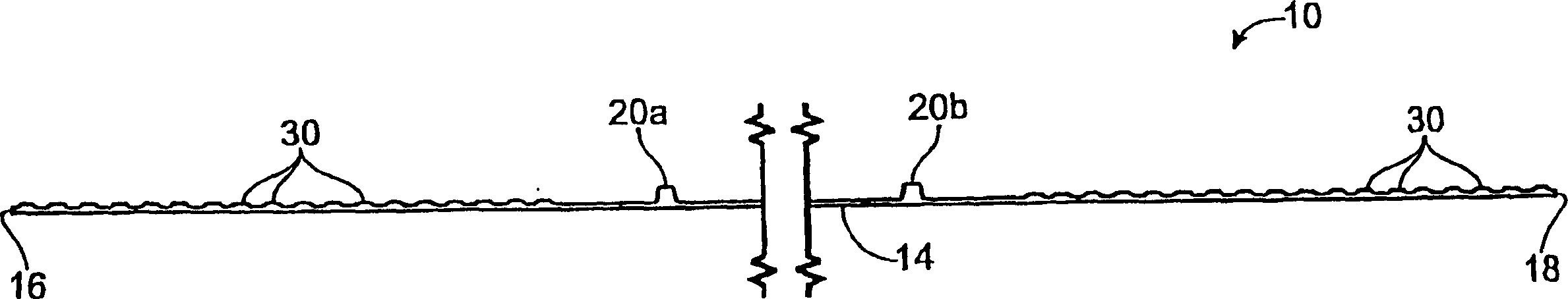

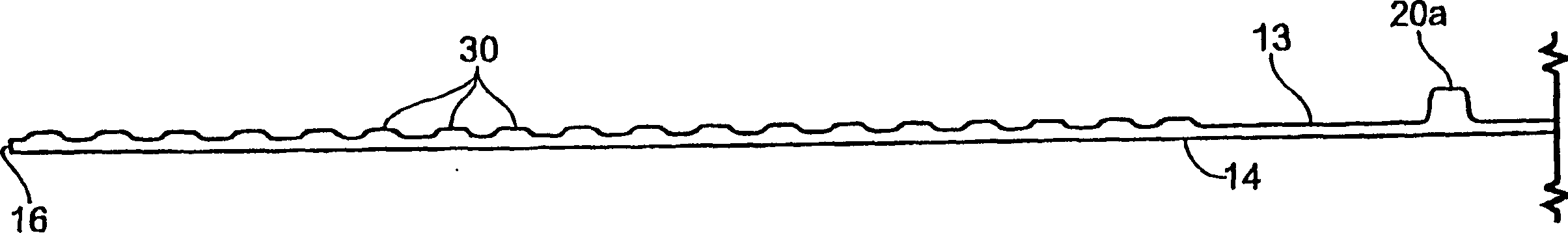

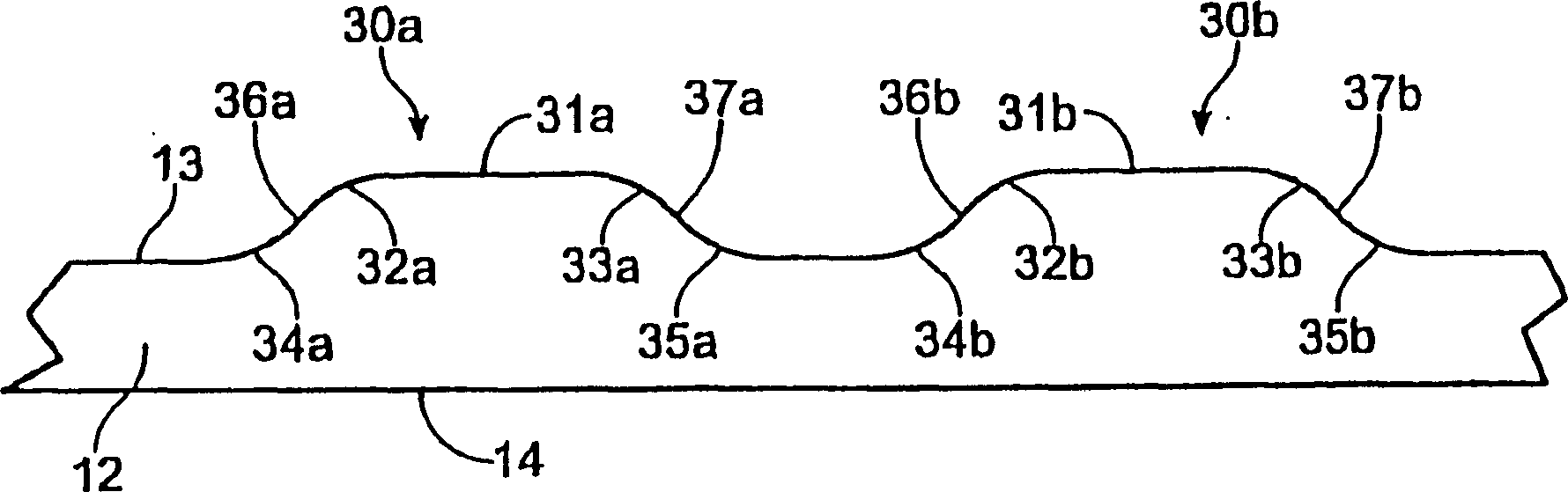

[0038] Fabrication of microporous polyethylene battery separators with the following features:

[0039] Partition width: 162.56mm

[0040] Back mesh thickness: 0.15mm

[0041] Main rib:

[0042] Quantity: 20

[0043] Height: 0.48mm

[0044] Width: 0.38mm

[0045] Spacing: 6.68mm

[0046] Small ribs:

[0047] Quantity: 18 (per flank)

[0048] Height: 0.10mm

[0049] Width: 0.25mm

[0050] interval:

[0051] Upper edge: 0.57mm

[0052] Center: 0.83mm

[0053] Bottom edge: 0.17mm

[0054] Others: 3.33mm (the distance between the centers of adjacent main ribs and small ribs)

example 2

[0056] The puncture resistance of the separators having the structure described in Example 1 was tested. The method used to test puncture resistance is a modified BCI test method 3.124. The modification consisted of replacing the needle dimensions determined in the original test method by needles with cross-sectional dimensions of 0.57 mm x 0.83 mm. The reason for using a needle instead is to use a needle that more closely approximates the small grid wires. The average puncture resistance for a large number of Example 1 separators was 0.75 lbs (1.65 kg).

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com