Hydraulic circuit control device of construction machinery

A technology for construction machinery and control devices, which is applied to fluid pressure actuating devices, construction, mechanical equipment, etc., and can solve problems such as intermittent feeling, inability to obtain acceleration, deceleration, and intermittent feeling in response to operation quantities. , to achieve the effect of agile reversal action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

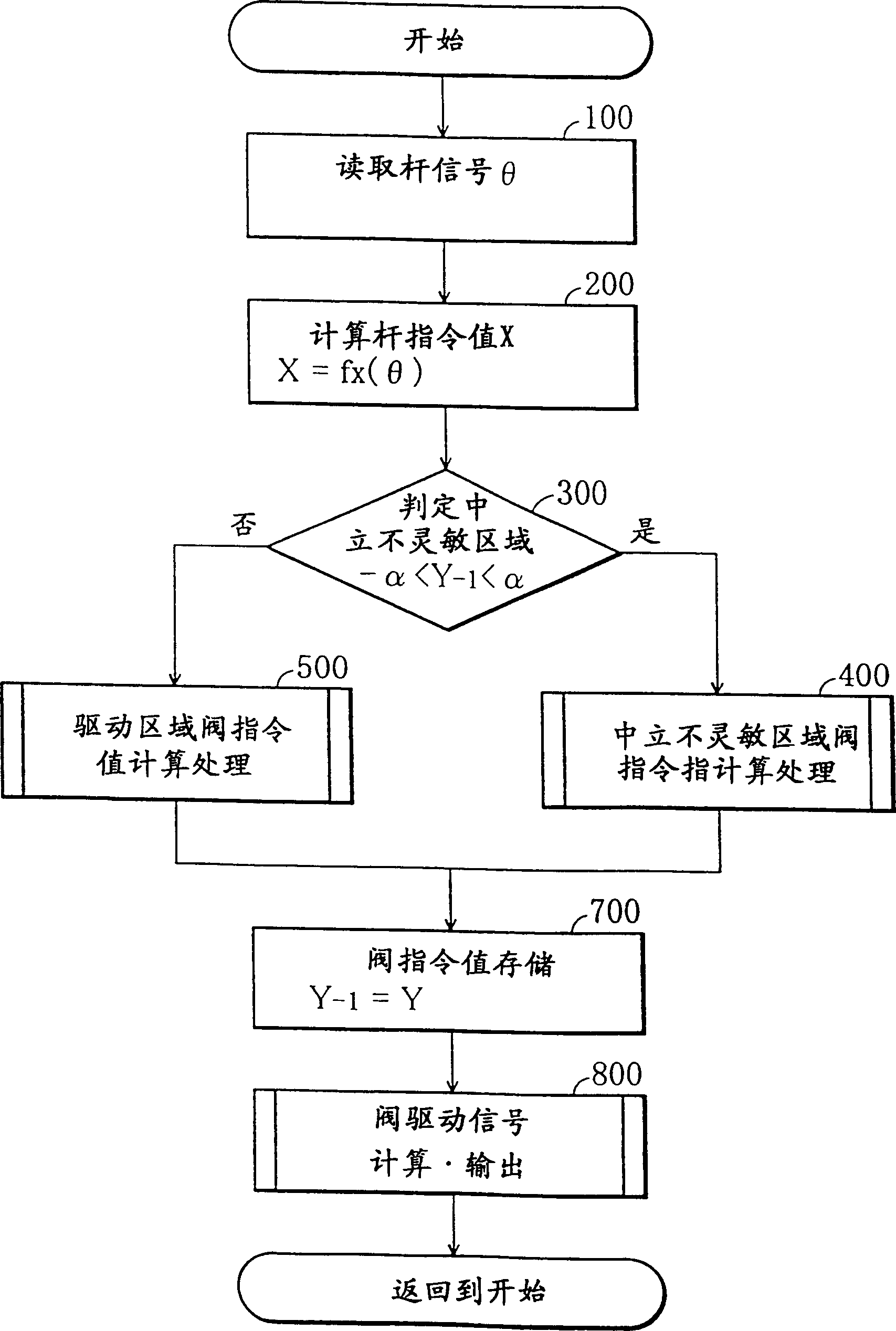

[0058] Hereinafter, embodiments of the present invention will be described based on the drawings.

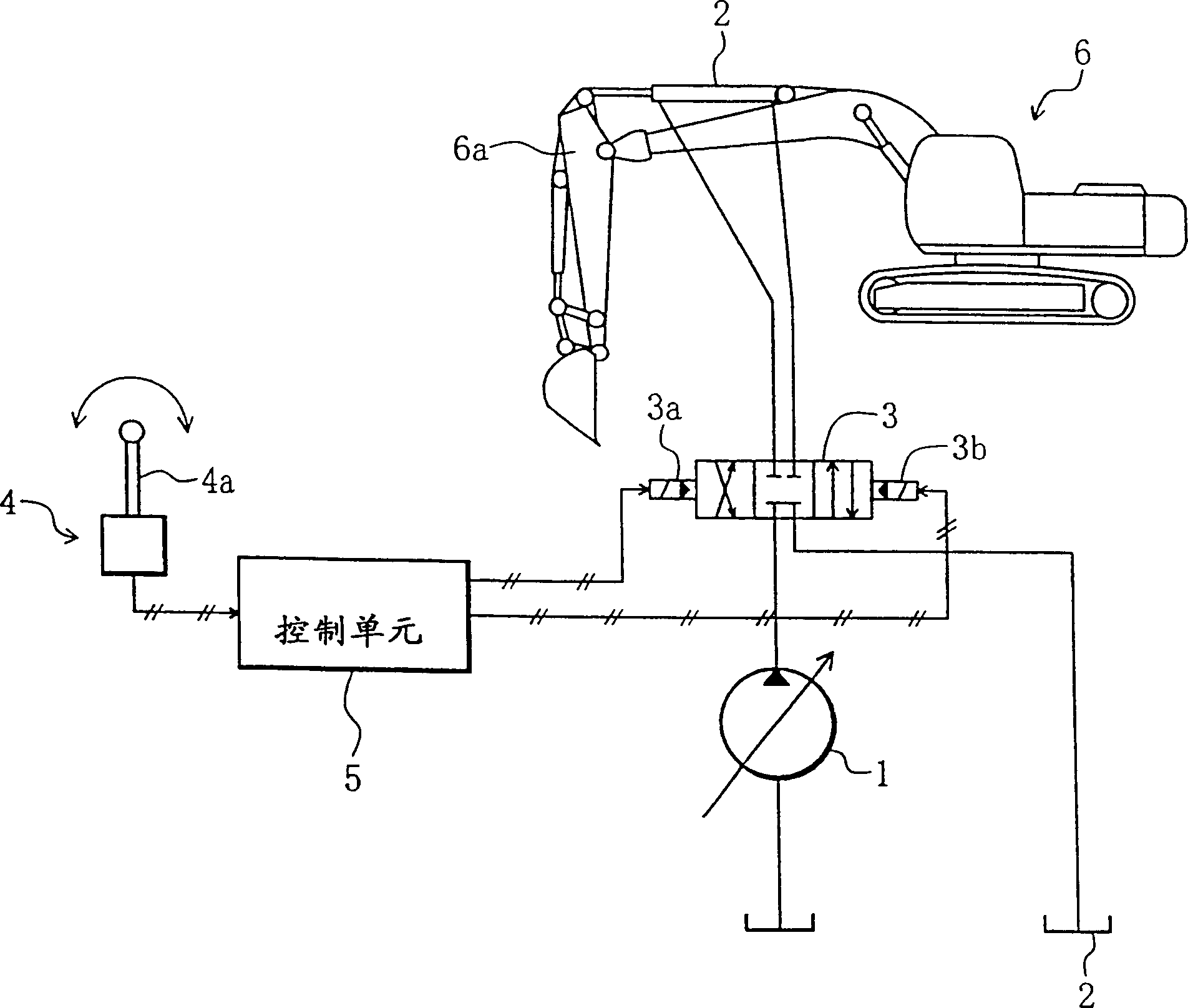

[0059] figure 1 This is an embodiment when the present invention is applied to a hydraulic circuit control device of a hydraulic forklift as a representative example of a construction machine. but, figure 1 For ease of description, only part of the hydraulic circuit control device associated with the hydraulic cylinder driving the fork arm of the hydraulic forklift is shown.

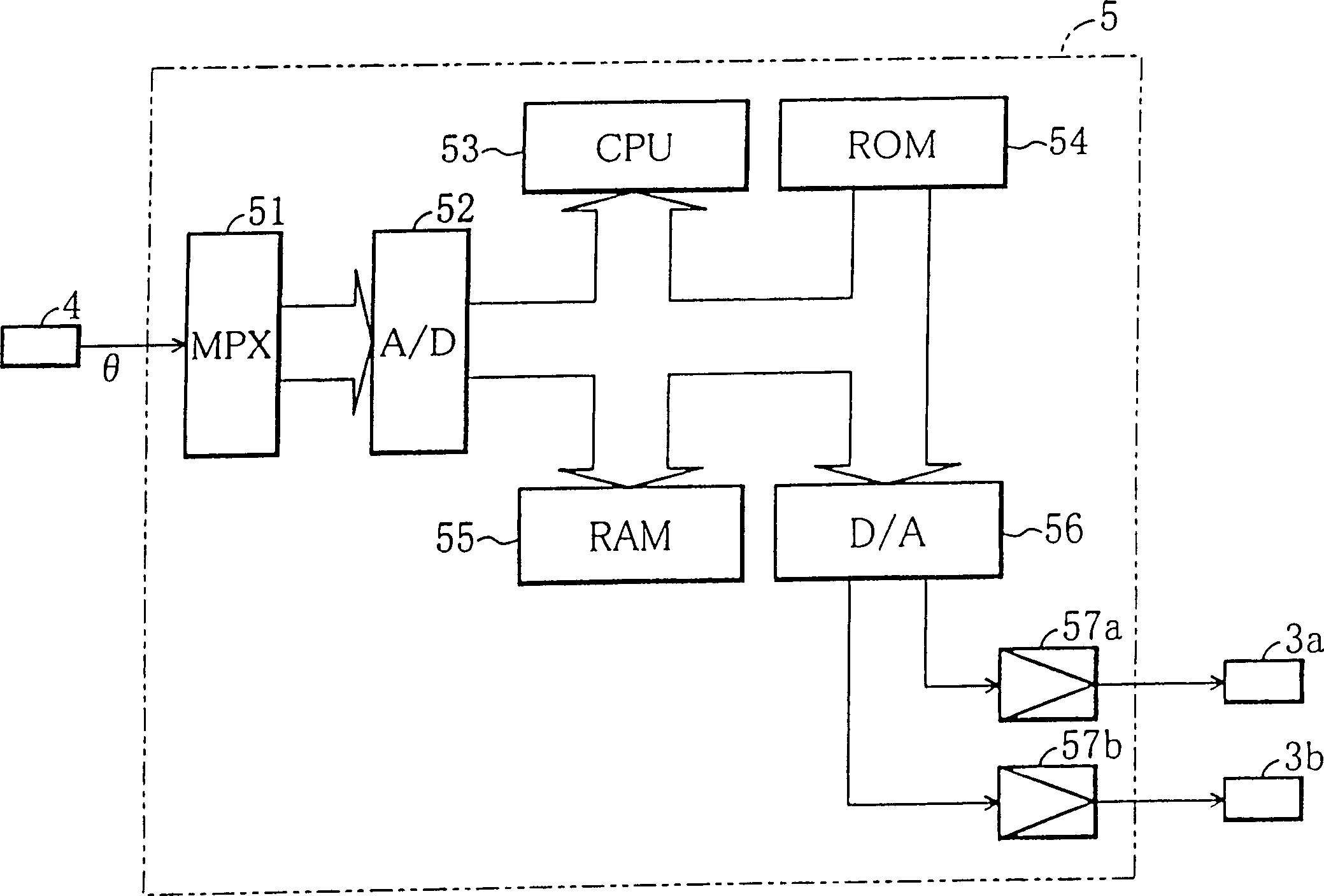

[0060] in figure 1 In the hydraulic circuit control device of this embodiment, a hydraulic pump 1, a hydraulic cylinder, etc., an actuator 2, a flow control valve 3 that controls the inflow direction and flow rate of the pressure oil discharged from the hydraulic pump 1 toward the hydraulic cylinder, and a drive flow rate The electromagnetic proportional valves 3a, 3b of the control valve 3, the operating lever device 4 having an operating lever 4a and outputting an electrical operation signal indicating t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com