Ink box equipped with saw tooth pressure regulating device

An ink tank and sawtooth technology, applied in the field of ink tanks, can solve problems such as functional limitations of adjusting pressure, redesign of bubble generators, and increasing difficulty in manufacturing and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

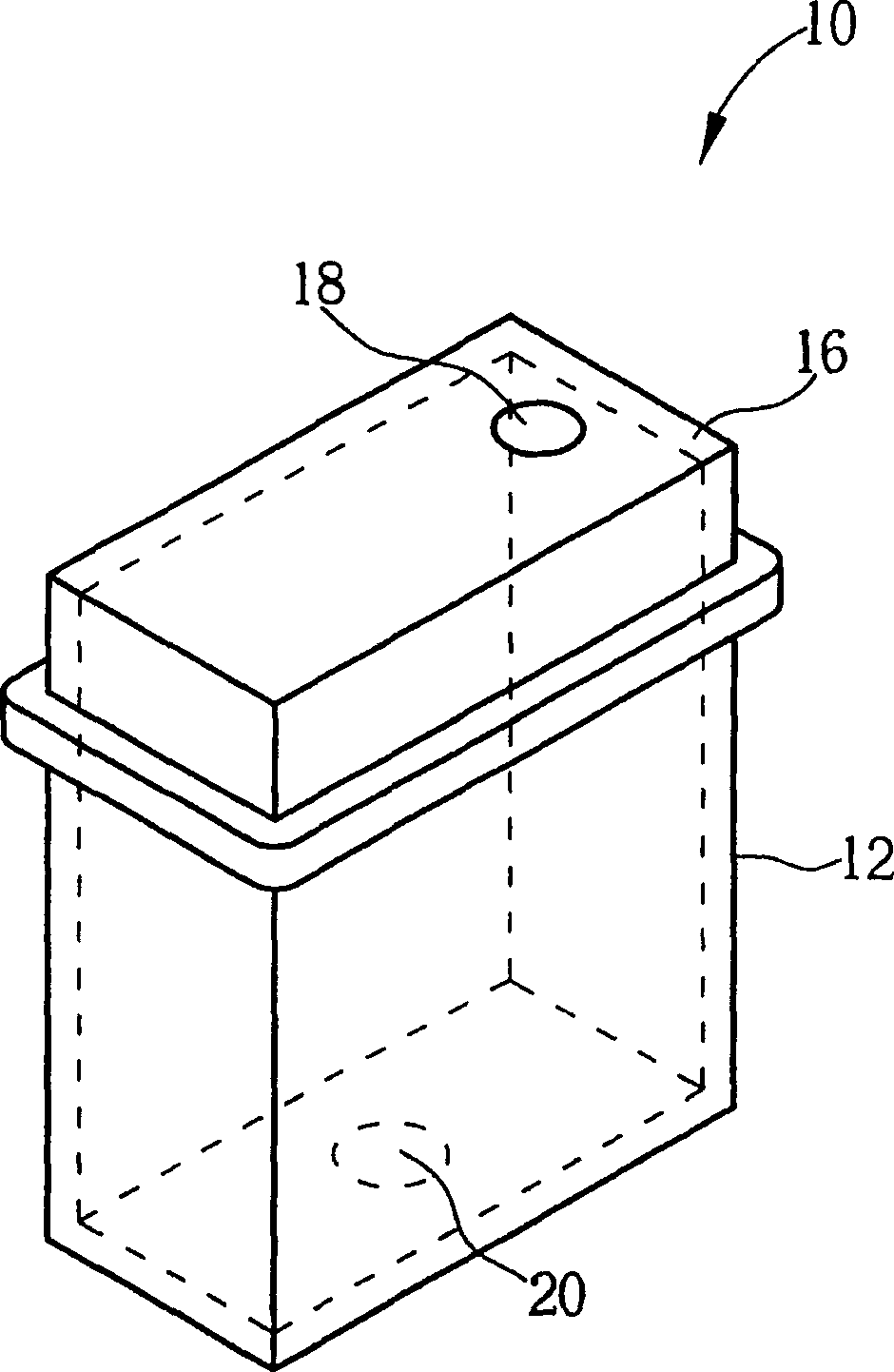

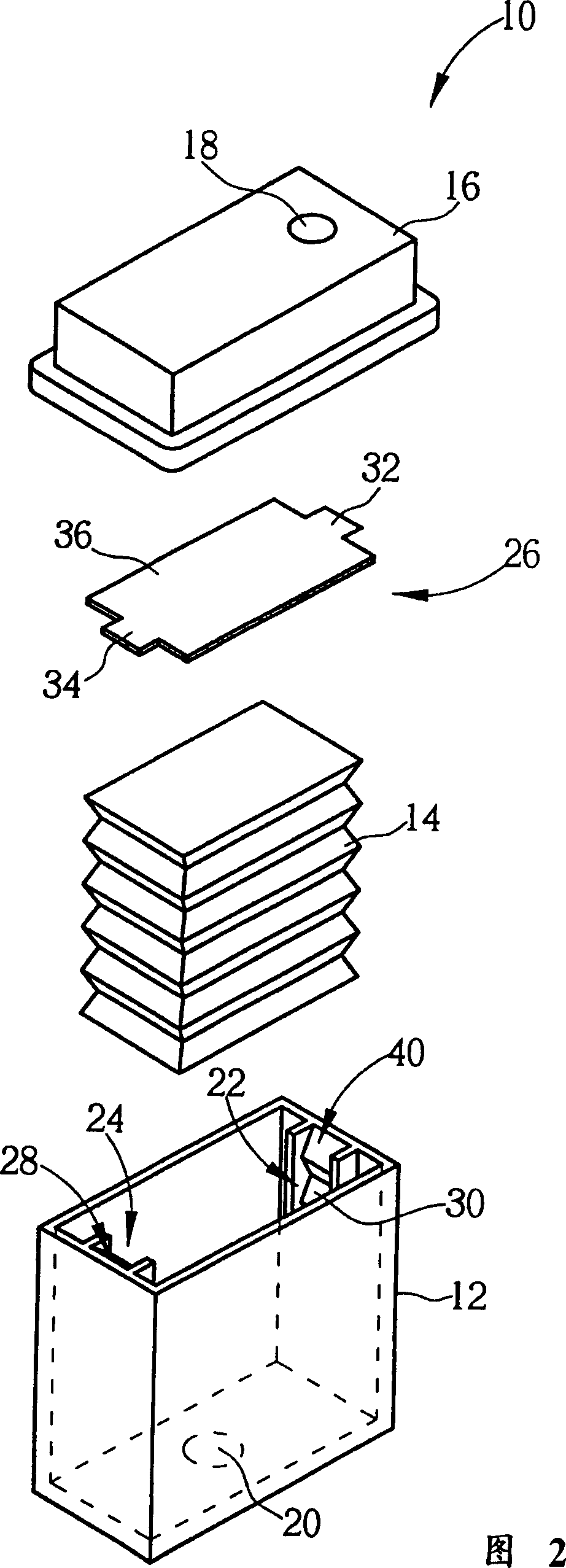

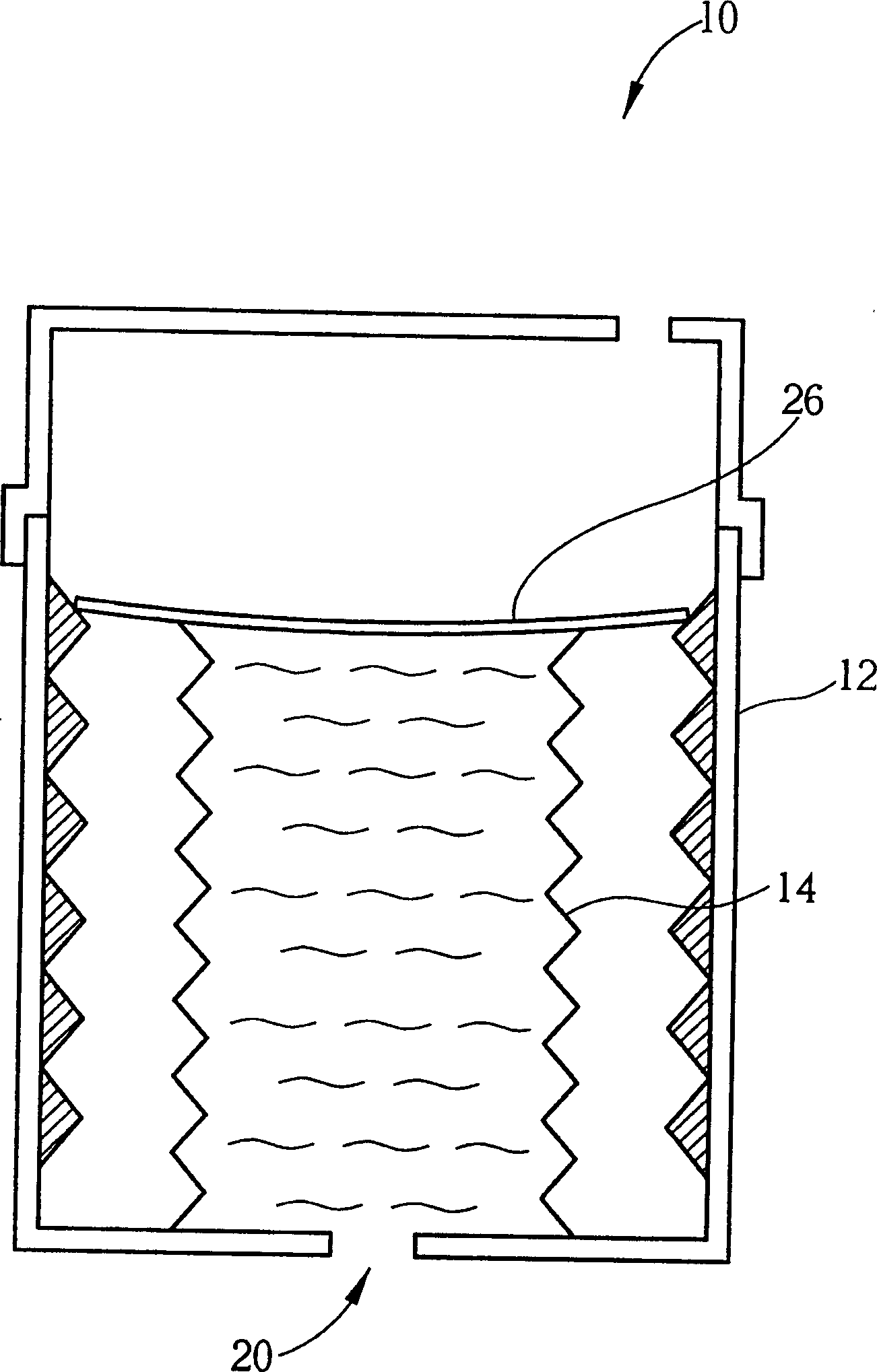

[0013] refer to figure 1 and Figure 2, figure 1 It is an external view of the ink cartridge 10 of the present invention, and Fig. 2 is figure 1 An exploded view of the components of the ink cartridge 10. The ink cartridge 10 includes a casing 12 inside which is provided a lantern-shaped ink bag 14 for storing ink (see FIG. 2 ). There is a top cover 16 above the housing 12 , and a vent hole 18 is arranged on it to balance the pressure difference between the inside and outside of the housing 12 . The bottom end of the casing 12 is provided with an ink outlet 20, which communicates with the ink bag 14 for supplying ink to an inkjet head (not shown) for inkjet printing.

[0014] The ink cartridge 10 uses the ink bag 14 to store ink and provides ink through the ink outlet 20. In order to prevent the ink from seeping out from the ink outlet 20 when the ink is not supplied, the ink bag 14 must be maintained within a certain negative pressure range. , to ensure that the inkjet hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com