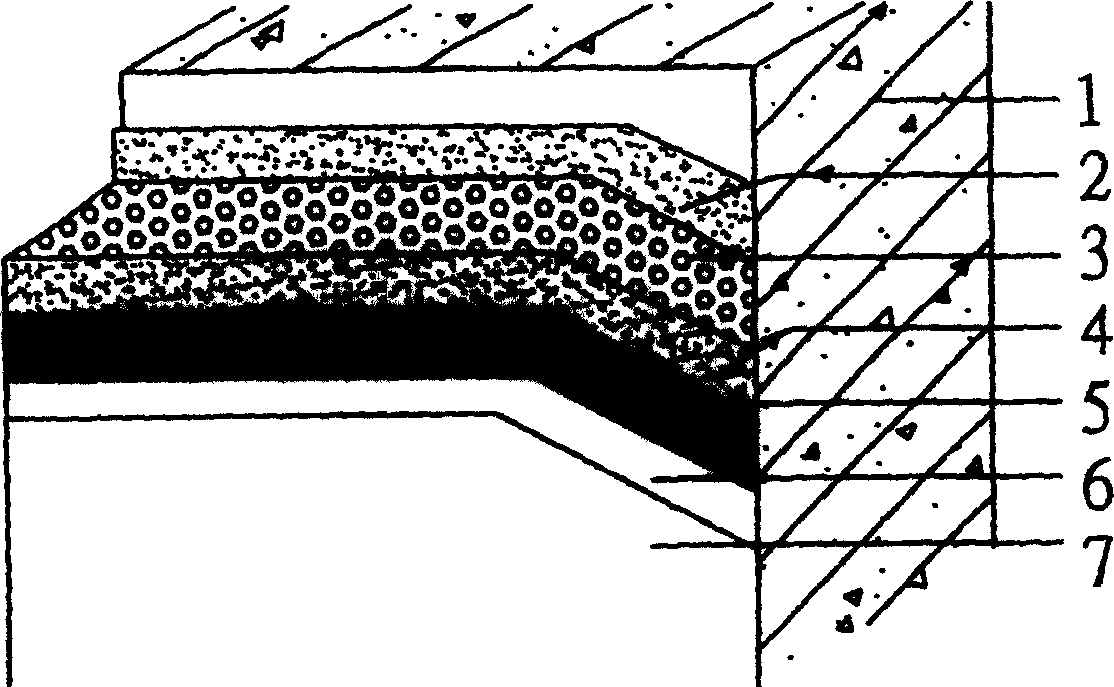

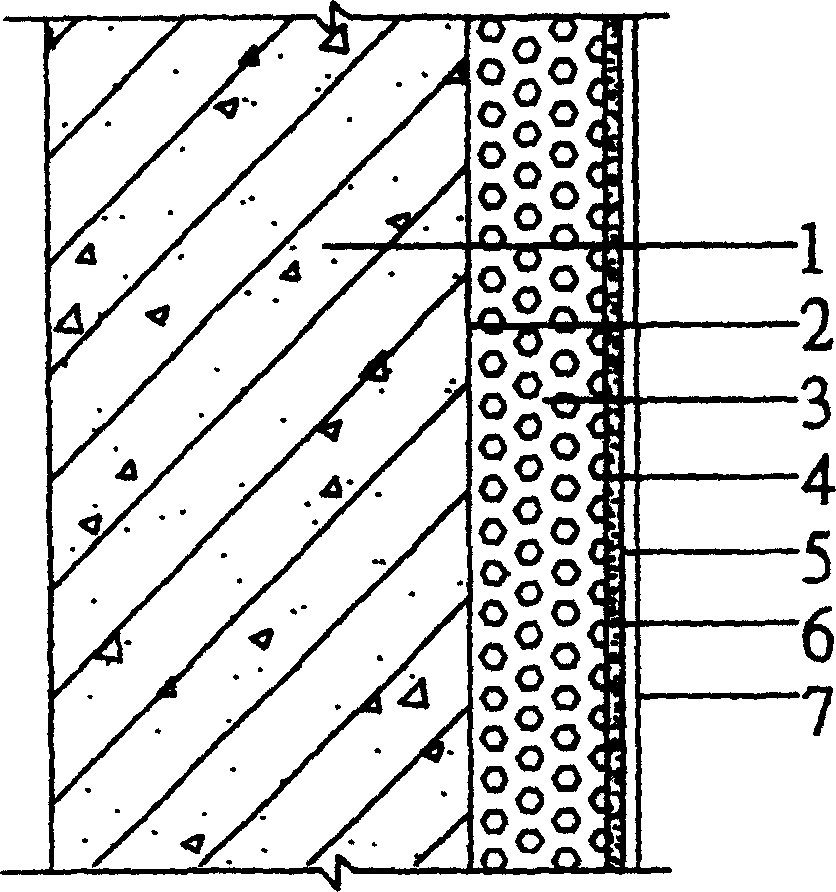

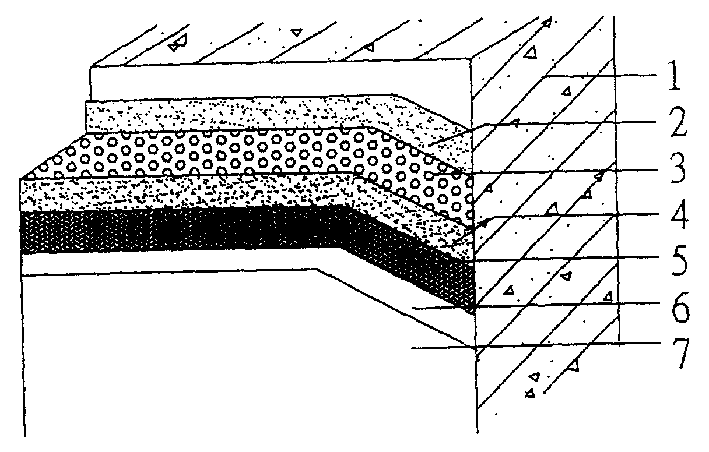

Anti-cracking inner thermal insulation wall and construction process

A technology for thermal insulation of walls and walls, applied in the direction of thermal insulation, walls, building components, etc., can solve the problem of easy cracking cost of thermal insulation and anti-crack protection layer, achieve the effect of reducing material cost, reducing cost, and enhancing crack resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0015] Embodiment, construction method step of the present invention:

[0016] a. During construction, firstly, thoroughly remove floating ash, oil stains, release agents, hollows and weathered substances on the surface of the base wall that affect the construction of the wall. When the protrusions on the wall surface are greater than or equal to 10mm, they should be removed;

[0017] b. Brush the interface mortar on the base wall;

[0018] c. Carry out the insulation layer construction, the insulation thickness should meet the design thickness requirements, and carry out the leveling treatment of the insulation layer;

[0019] d. Apply anti-cracking gypsum 3mm-10mm thick and perform leveling treatment;

[0020] e. Paste the non-woven fabric with an adhesive on the anti-crack gypsum surface layer, and use butt joints at the seams of the non-woven fabric, and no wrinkles are allowed when the non-woven fabric is pasted;

[0021] f. Flexible putty for scraping interior walls; ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap