Control method of conveyer belt sorting machine

A control method and conveyor belt technology, which is applied in sorting and other directions, can solve problems such as high production cost, wrong sorting, and high requirements for conveyor belt running speed accuracy, and achieve low requirements for working environment conditions, no strict requirements for stability, and sorting Controlling Accurate and Reliable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

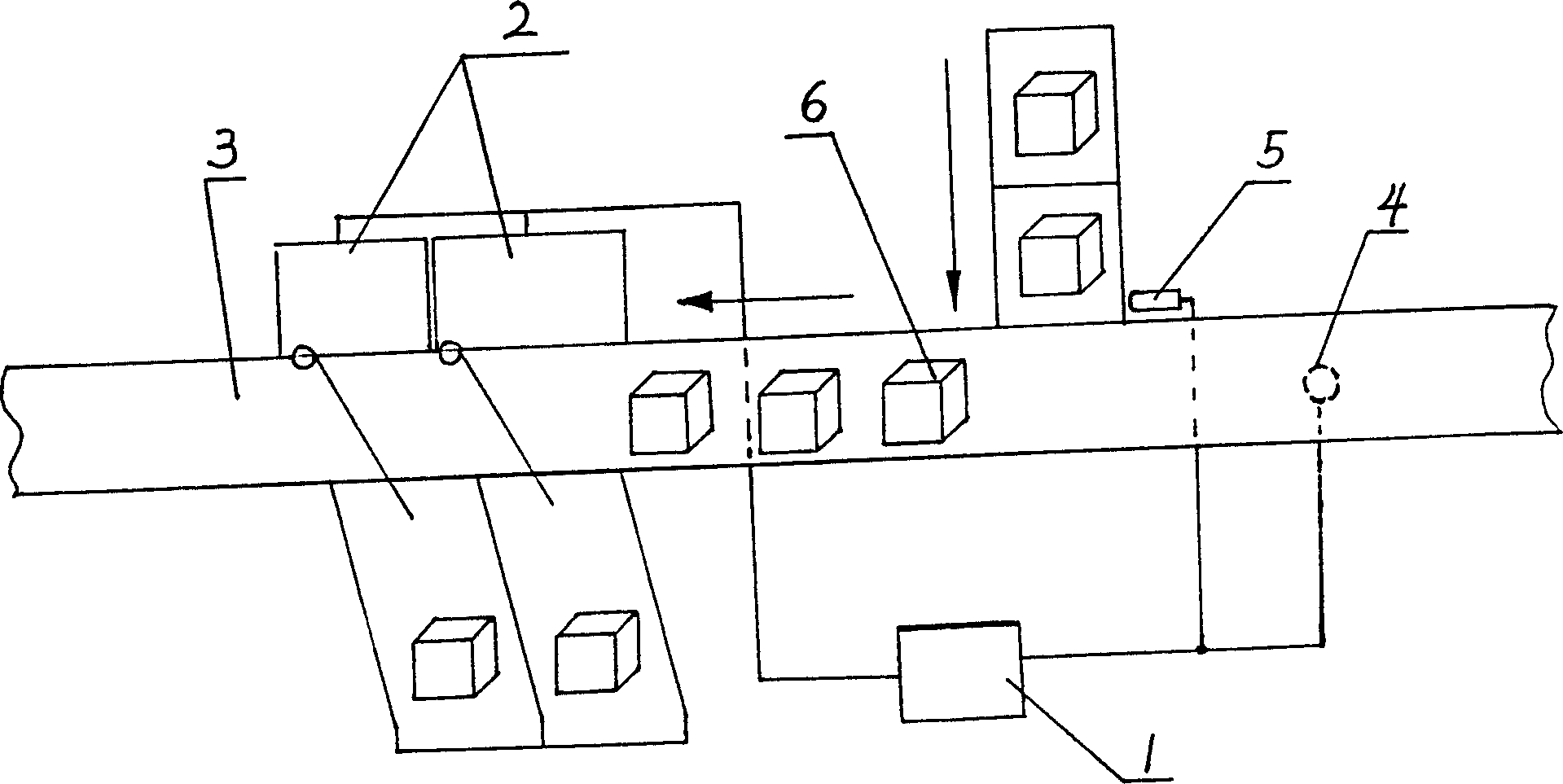

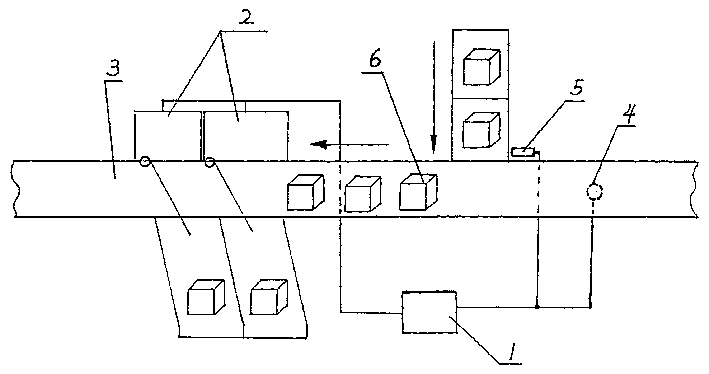

[0007] Embodiments of the present invention: the conveyor belt sorter of the present invention can adopt any type of conveyor belt sorter in the prior art, and its computer controller (1) can adopt an industrial computer controller or a common microcomputer, and make the computer controller (1) 1) According to the conventional control method, the action of the sorting actuator (2) installed on each object sorting port of the conveyor belt sorter can be controlled, and during production, the movement mechanism of the conveyor belt (3) of the conveyor belt sorter The upper moving signal sensor (4) is installed on the side, and the upper belt detection device (5) of the upper object is installed on the upper object of the conveyor belt sorter. The mobile signal sensor (4) and the detection device (5) can be used on the market. Assemble the finished product, so that the movement signal sensor (4) can convert the position movement change of the conveyor belt (3) into a pulse signal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com