Low-voltage circuit breaker composing a switching chamber and a displaceable contact bearer

A low-voltage circuit breaker and switch box technology, which is applied in the directions of circuit breaker contacts, circuit breaker components, and electrical switches, can solve the problems of increasing pole distance, large width error, and error generation, and achieves low motion resistance and favorable The effect of size design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

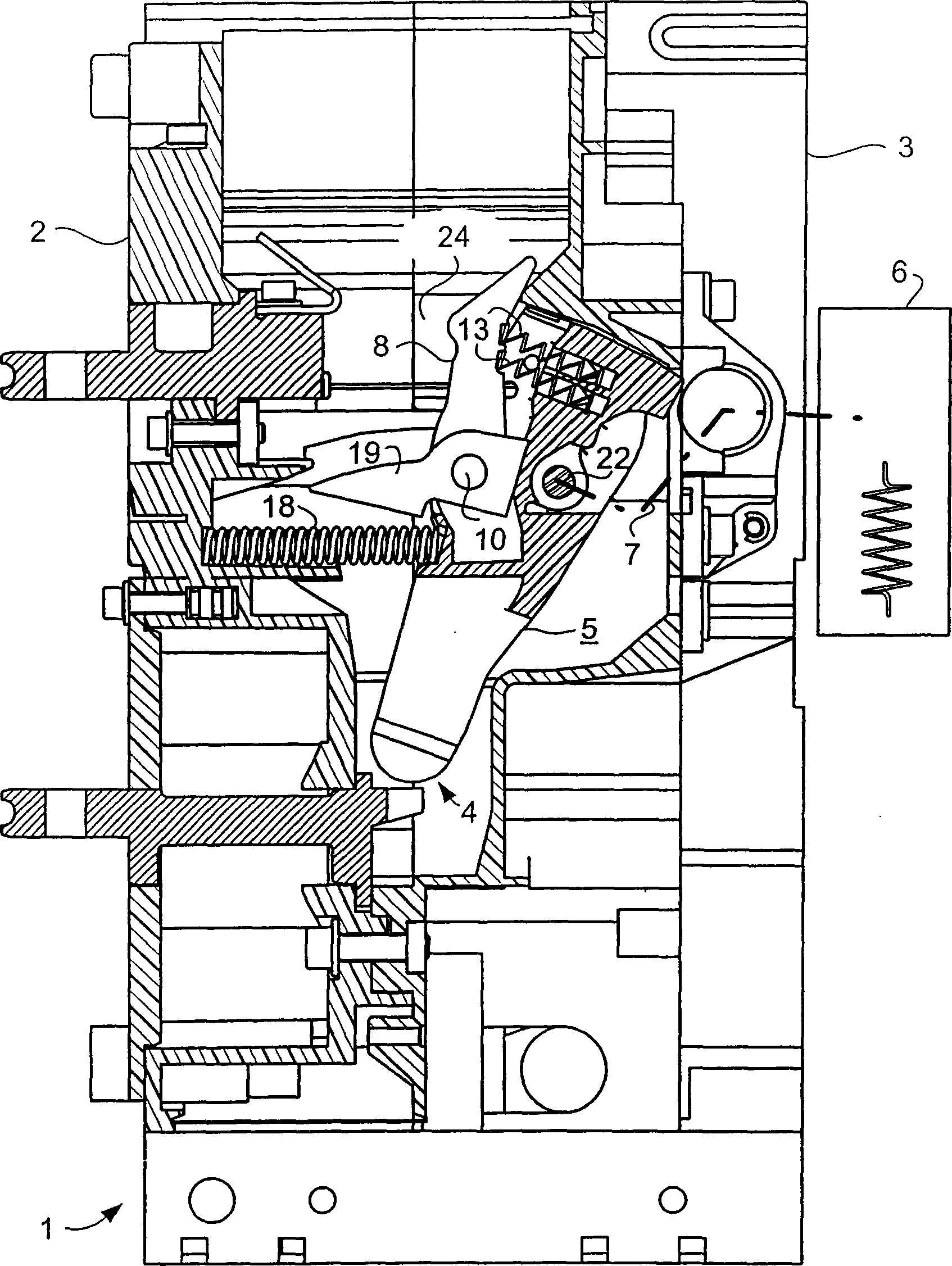

[0024] figure 1 The switch box 1 of the low-voltage circuit breaker represented in is composed of a rear wall 2 and a front part 3 . The rear wall 2 supports, in a known manner, connection curves for the connection of the circuit breaker to an external circuit. In the region of the junction between the rear wall 2 and the front part 3 there is a bearing point 4 for pivotably mounting the contact bearing 5 . The driver 6 schematically shown in the figure and the lever system 7 connecting the driver 6 and the contact support 5 are used to rotate the contact support 5 around the support point 4 in order to switch on and off the circuit breaker.

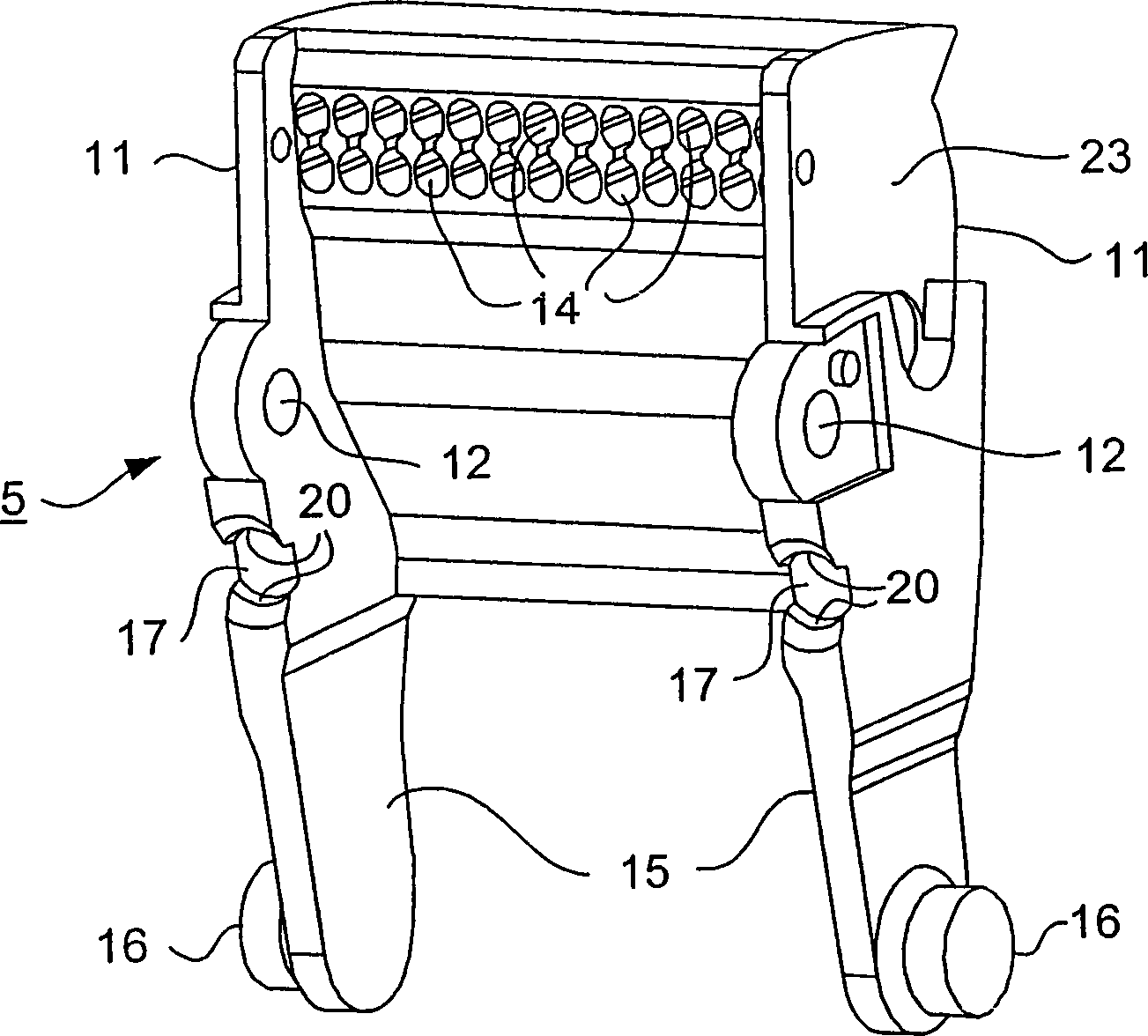

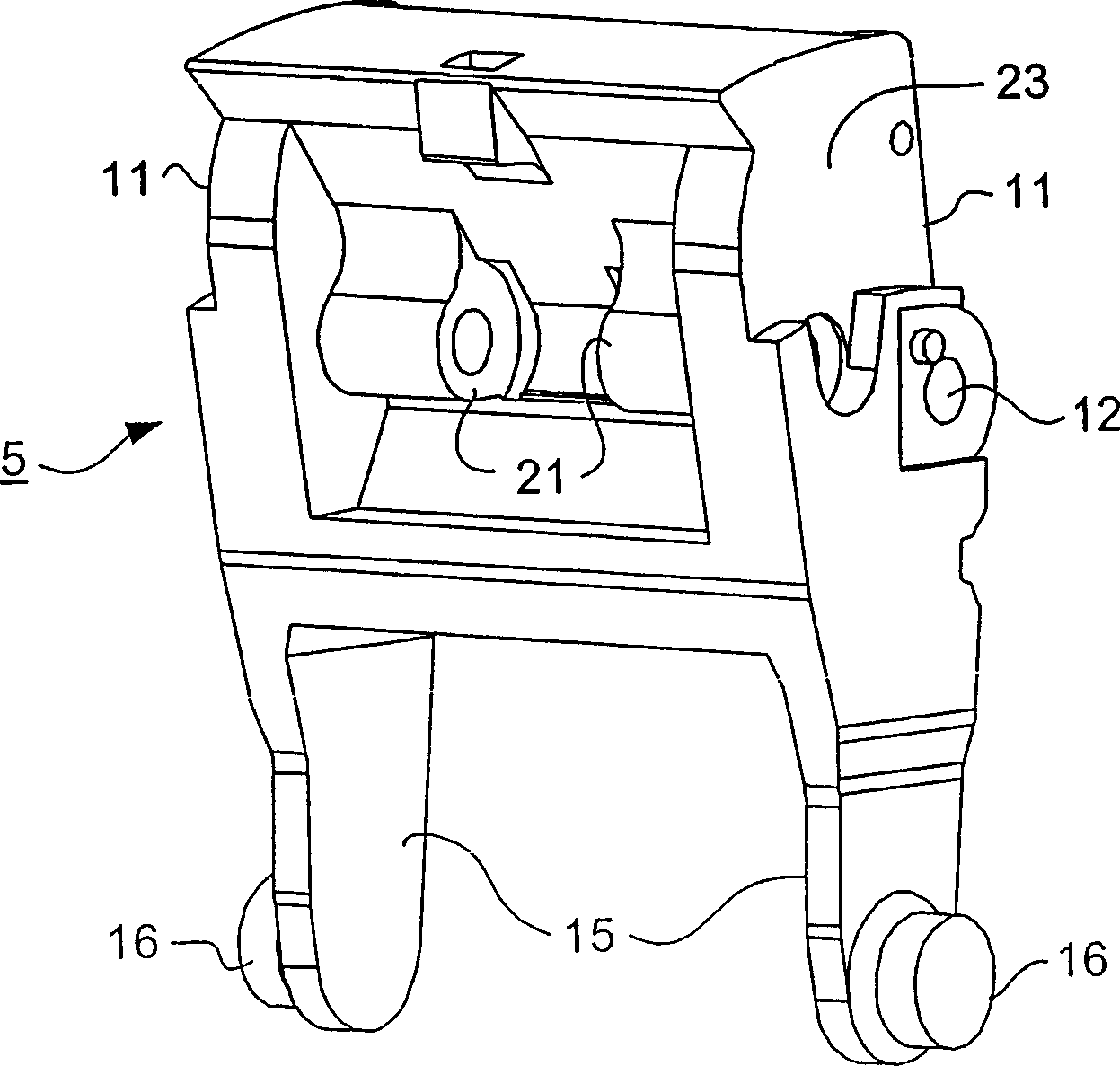

[0025] refer to below figure 2 and 3 To further illustrate the contact support, since these two figures can be compared with only the figure 1 The individual features of the contact carrier 5 can be seen more clearly.

[0026] The contact support 5 is used to place the contact rod 8 ( figure 1 ), the number of contact rods corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com