Machining Technology of the Eccentric Circle of the Joint Part of the Pump Body

A processing technology, eccentric circle technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of no tool setting benchmark, too long tool protruding, insufficient tool strength, etc., to ensure roughness, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings.

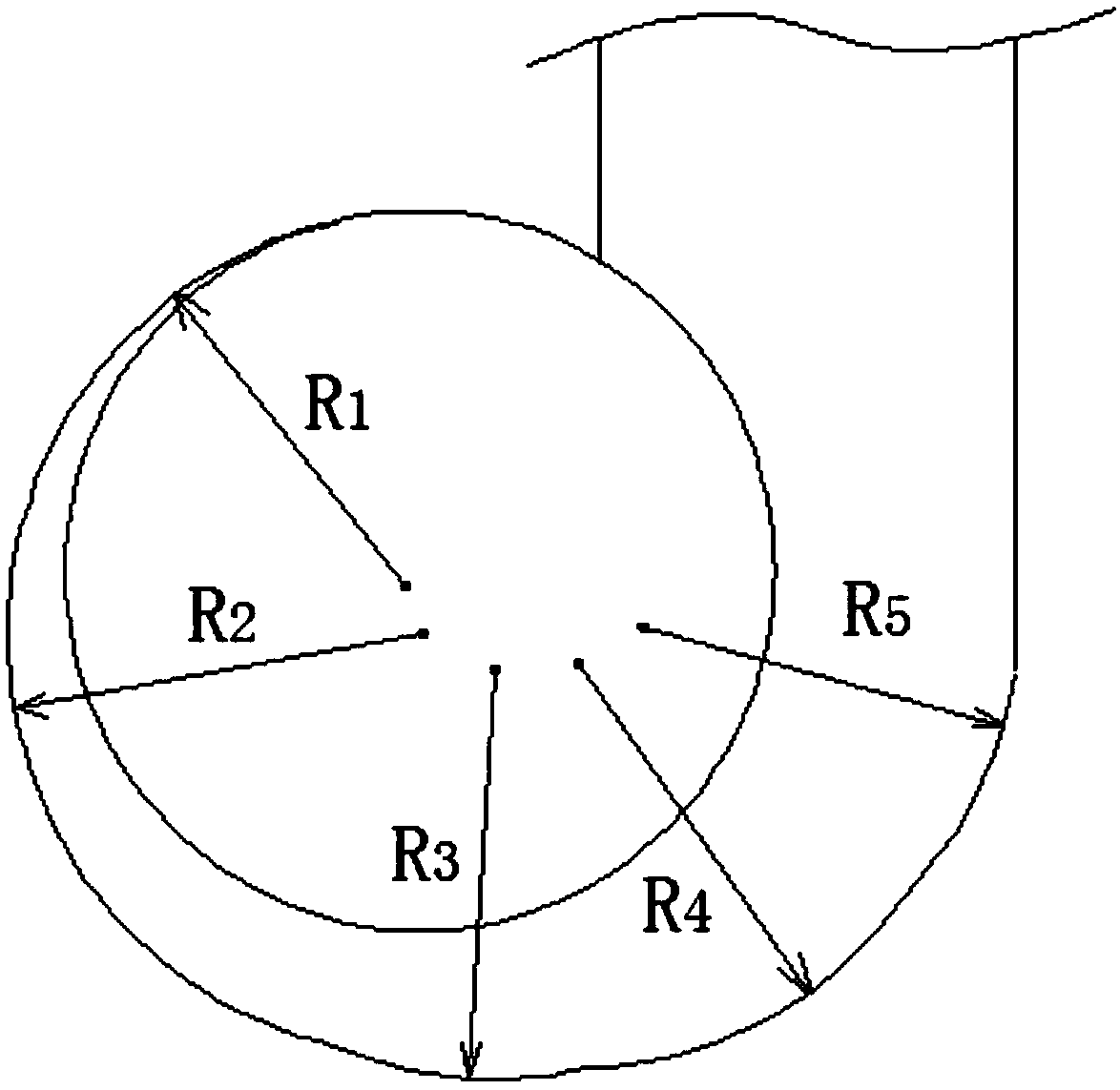

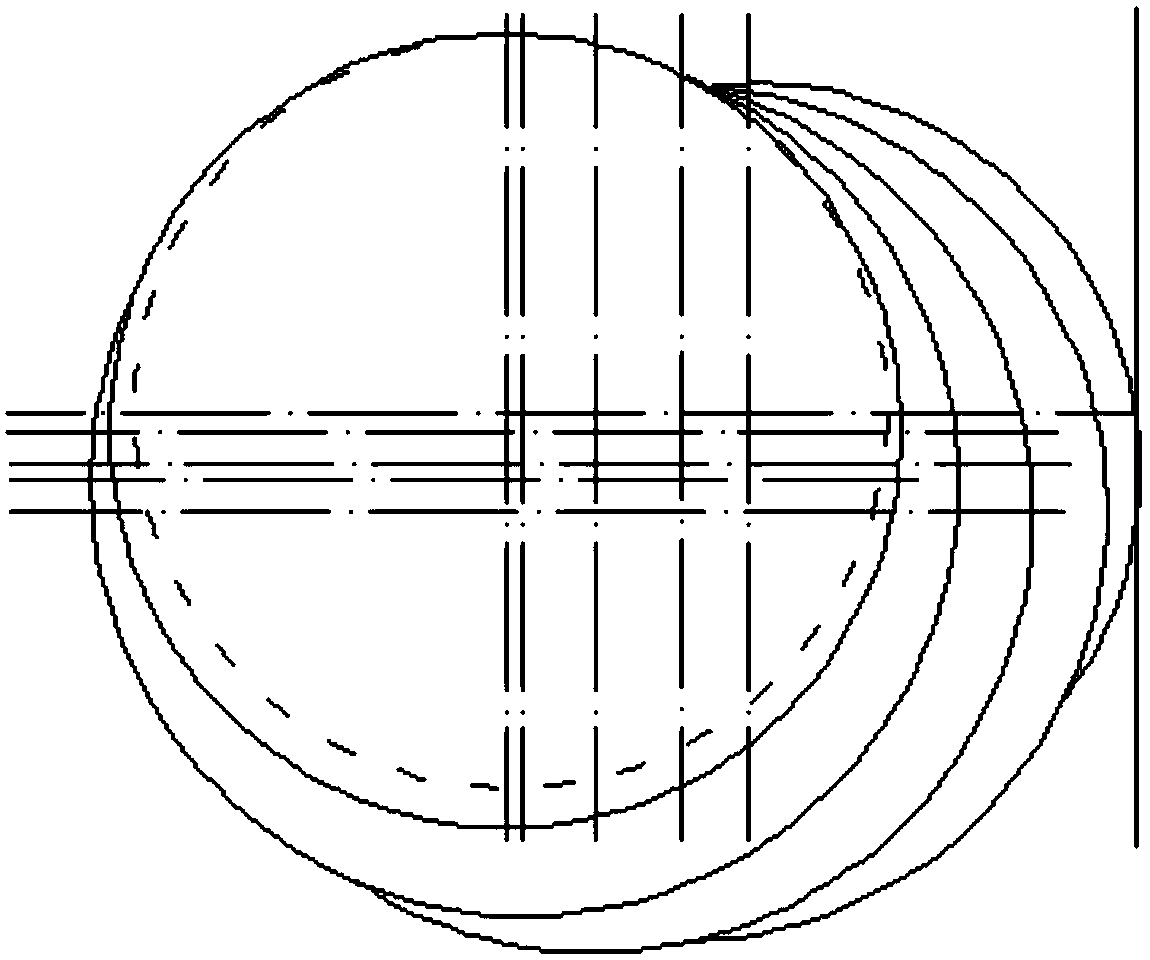

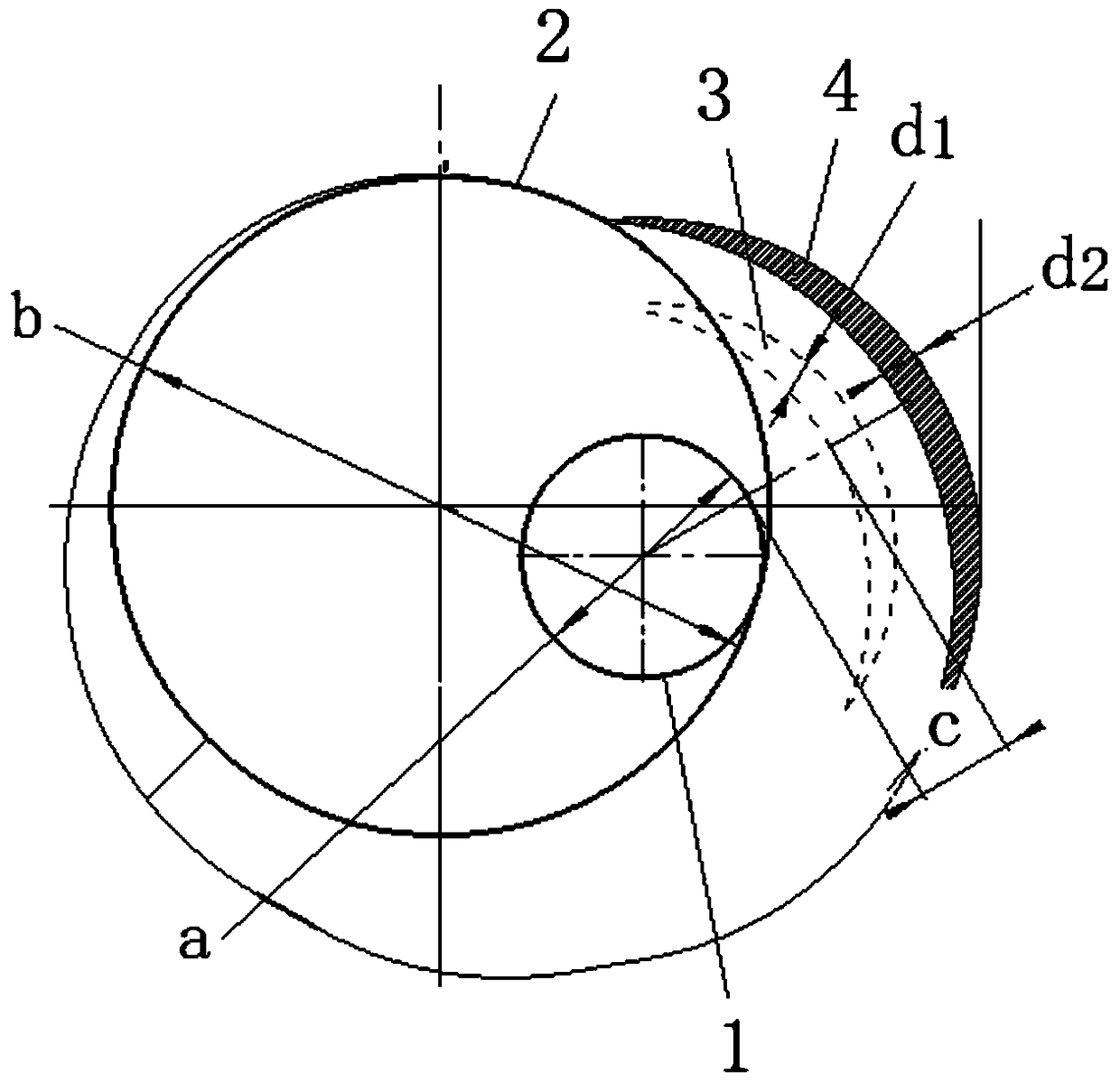

[0047] Such as Figure 1~4 As shown, in this embodiment, five eccentric circles with different radii are designed in the basic circle of the abdominal cavity junction of the pump body, and the radii of the five eccentric circles are respectively R 1 , R 2 , R 3 , R 4 and R 5 , each eccentric circle smoothly connects in turn to form the arc-shaped cavity wall of the abdominal cavity of the pump body, such as Figure 4 and Figure 14 As shown, the section of the arc-shaped cavity wall includes a straight wall section in the middle and rounded corner sections with a radius R on the upper and lower sides of the straight wall section.

[0048] With the completion of each eccentric circle processing step, when the fourth eccentric circle is processed, most of the processing work has been completed at the abdominal cavity junction of the pump body, and only a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com