Method and devices for producing textile lap

The technology of a cotton net and an adjusting device is applied in the field of producing textile cotton nets to achieve the effect of increasing the output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

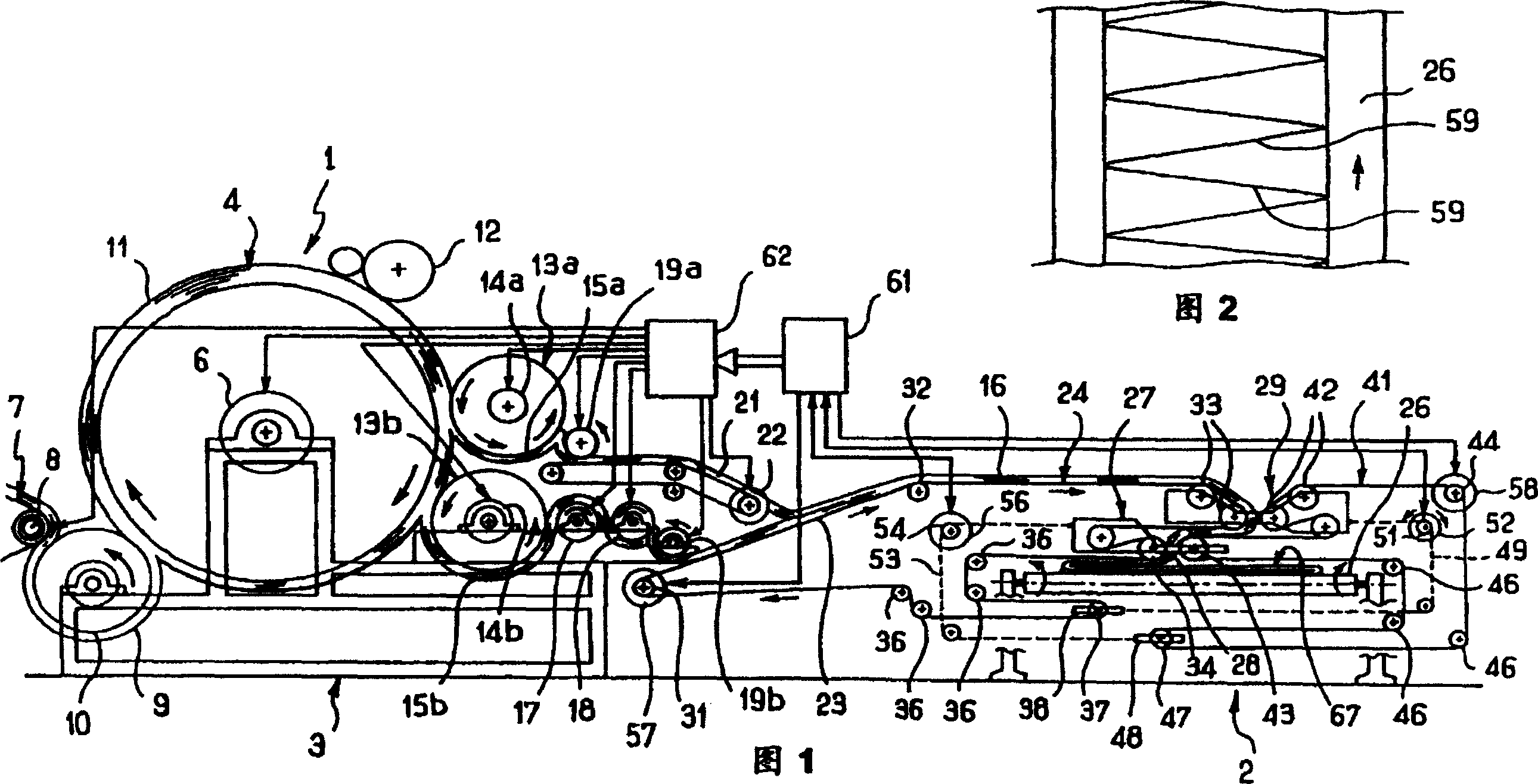

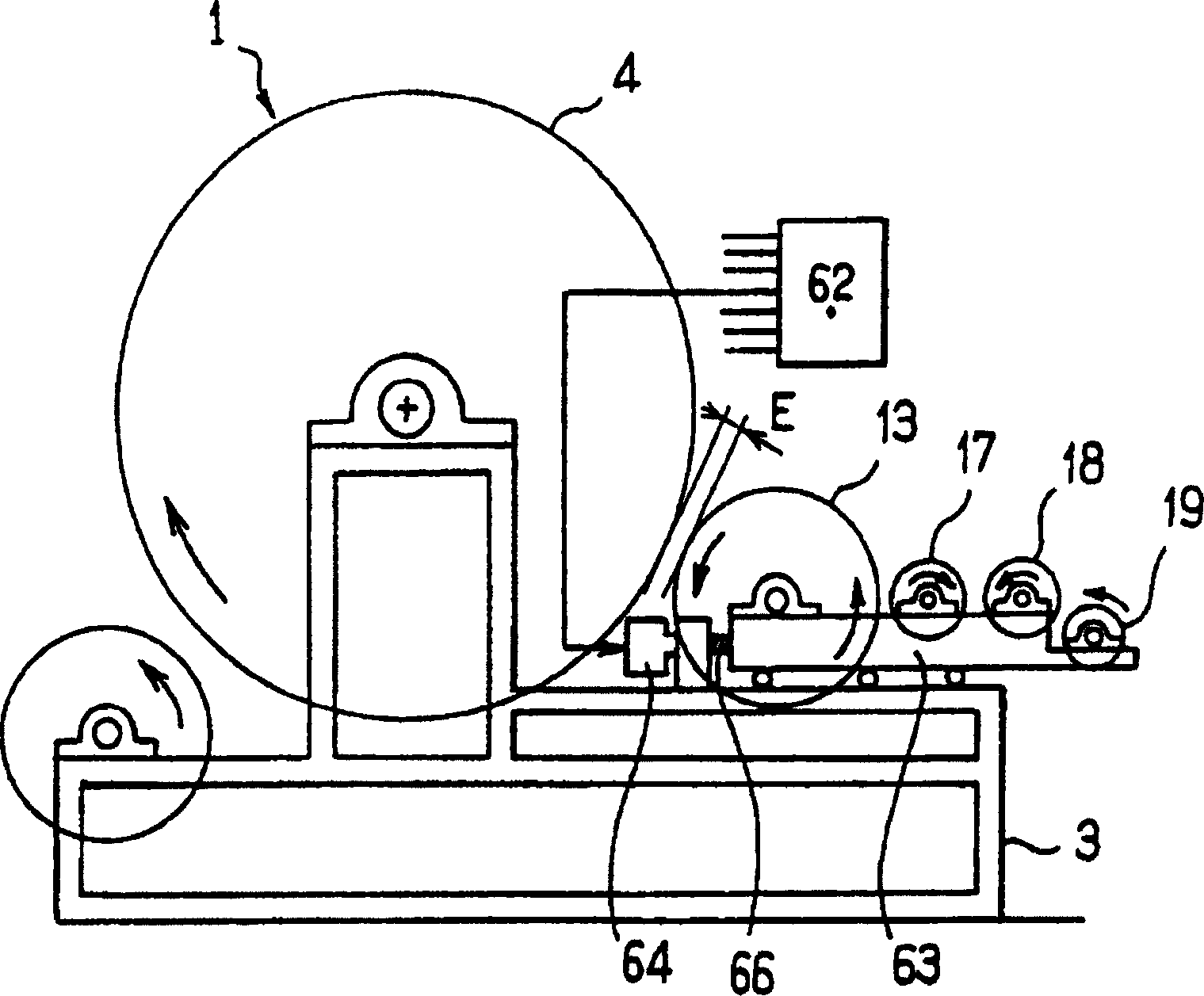

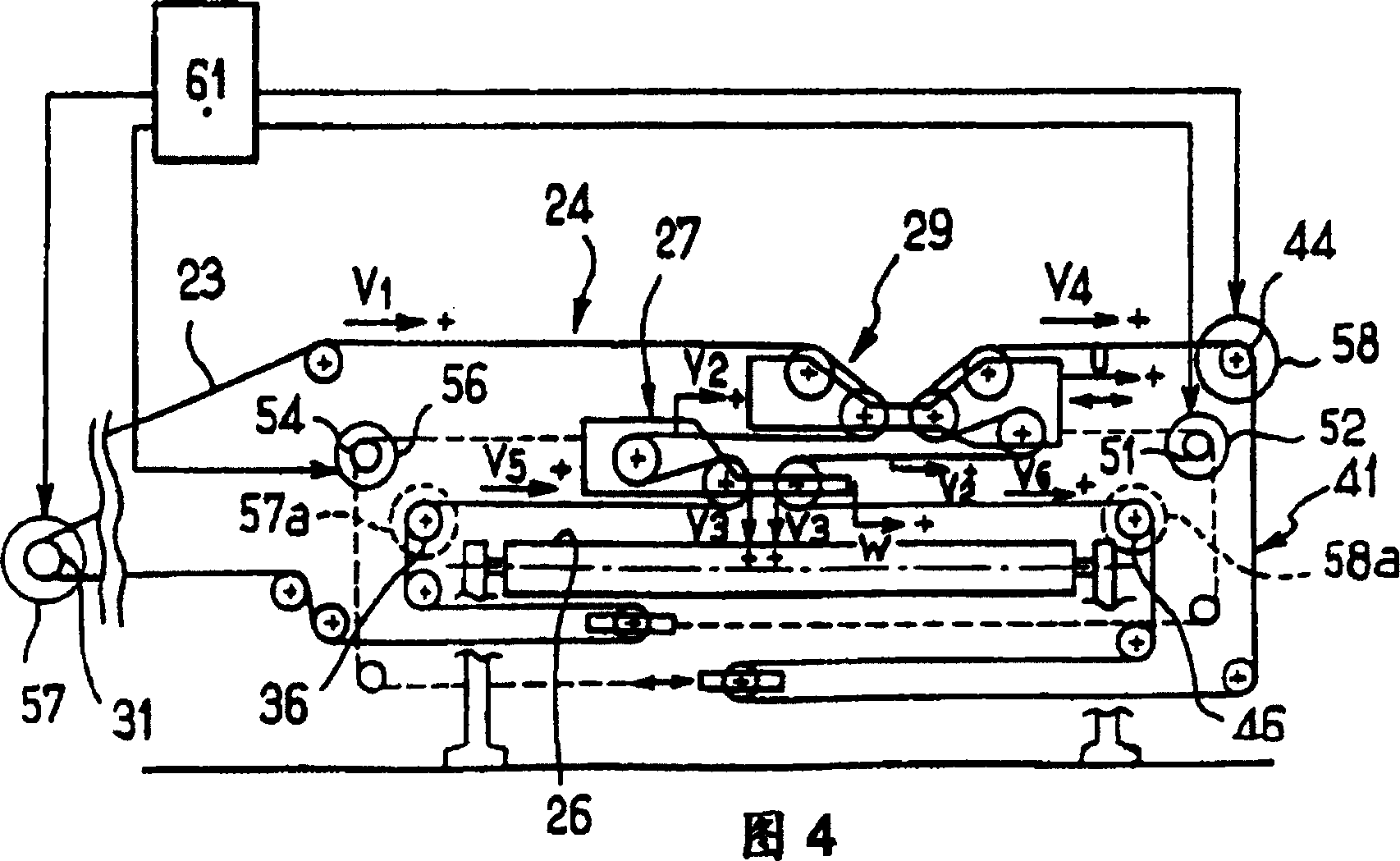

[0066] In the example of FIG. 1 , the apparatus comprises a card 1 and a crosslapper 2 .

[0067] The card 1 comprises a frame 3 supporting a carding cylinder 4 which is driven in rotation by an electric motor 6 . The frame 3 also supports at least one "cotton feeder" 7 consisting essentially of a conveyor belt driven in rotation by an electric motor 8 . The cotton feeding device 7 is loaded with textile fibers 9 from a reservoir and is usually deposited on the periphery of the cylinder 4 with the intermediary of at least one cylinder 10 . Thus, the cotton feeding device 7 regularly regenerates a layer of fibers 11 on the periphery of the cylinder 4 . Around the periphery of the cylinder 4 there are several cylinders of known type, such as 12, (only a pair of which are shown here for the sake of clarity), which are used to work the fibers, especially to place them on the cylinder 4. Orientation is done around the periphery.

[0068] The fibers from the cotton feeder 7 arriv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com