Electric brush holder for rotary motor

A technology for rotating electrical machines and holding devices, applied in electromechanical devices, rotating current collectors, circuits, etc., can solve problems such as inability to respond quickly, increase in vibration area, and increase in brush prices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiment 1

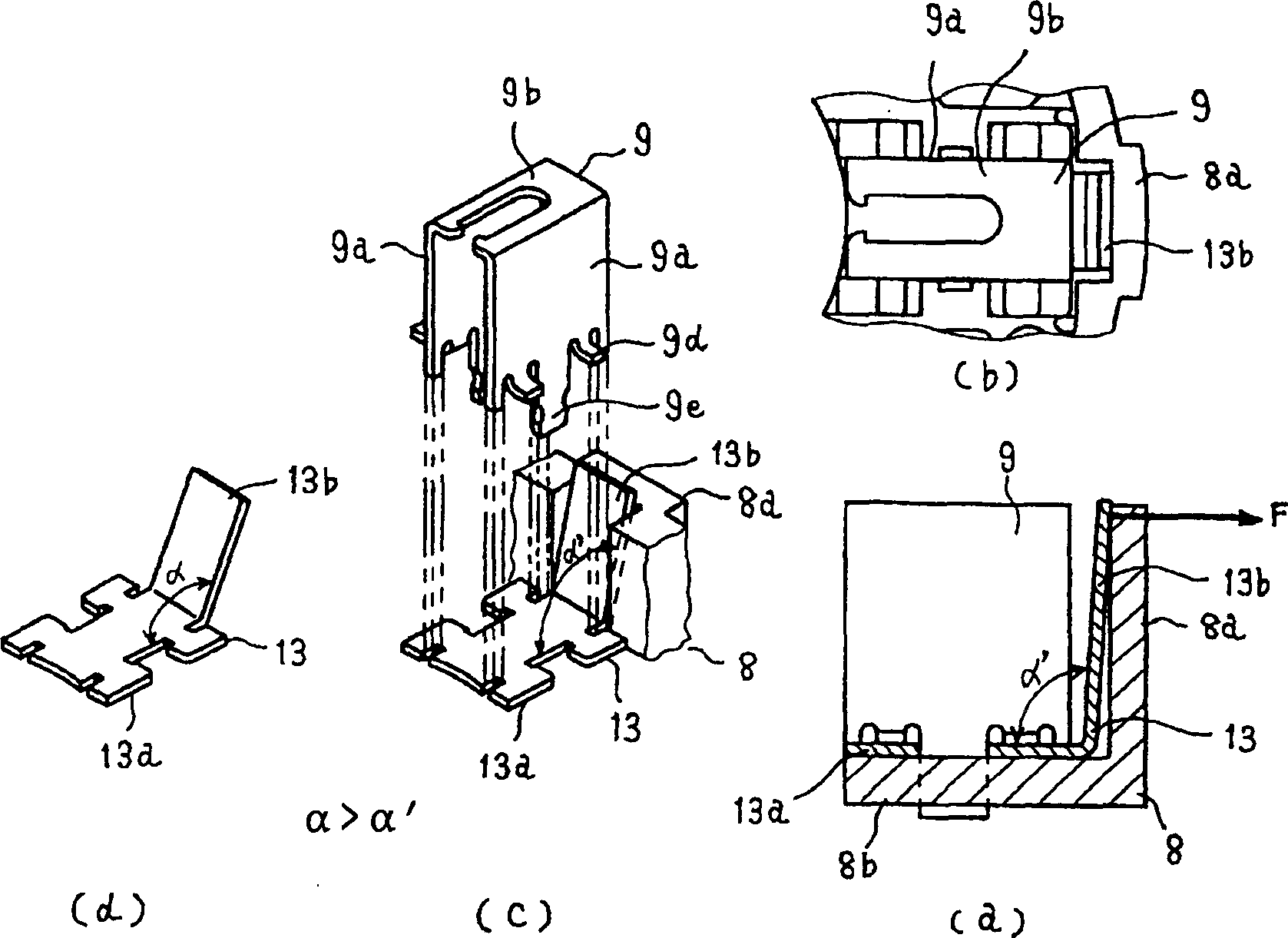

[0029] figure 1 is a structural diagram of a brush holding device according to Embodiment 1 of the present invention, figure 2 with image 3 As an explanatory diagram for explaining its effects, the same parts as those of the above-mentioned conventional example are assigned the same symbols. exist figure 1 Among them, 8 is a retainer mounting body composed of an arc-shaped outer wall portion 8a and a base plate portion 8b, and 9 is a front end portion with two side walls 9a and an upper wall 9b made into a "U" shape and a "U" shape. The brush holder with the protrusion 9c for the riveting part and the protrusion 9d for the fixed position, 13 is a spring holder, which is installed on the brush holder installation body 8 together with the brush holder 9, forming a "U" shape The wall part 13a of the bottom surface wall of the brush holder 9 and the holding part 13b which is located at the counter-commutator side opening of the brush holder 9 and supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com