Weft yarn brake for loom

A technology of brakes and weft yarns, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problems of easy torn weft yarns and the possibility of brake adjustment not being fully satisfactory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

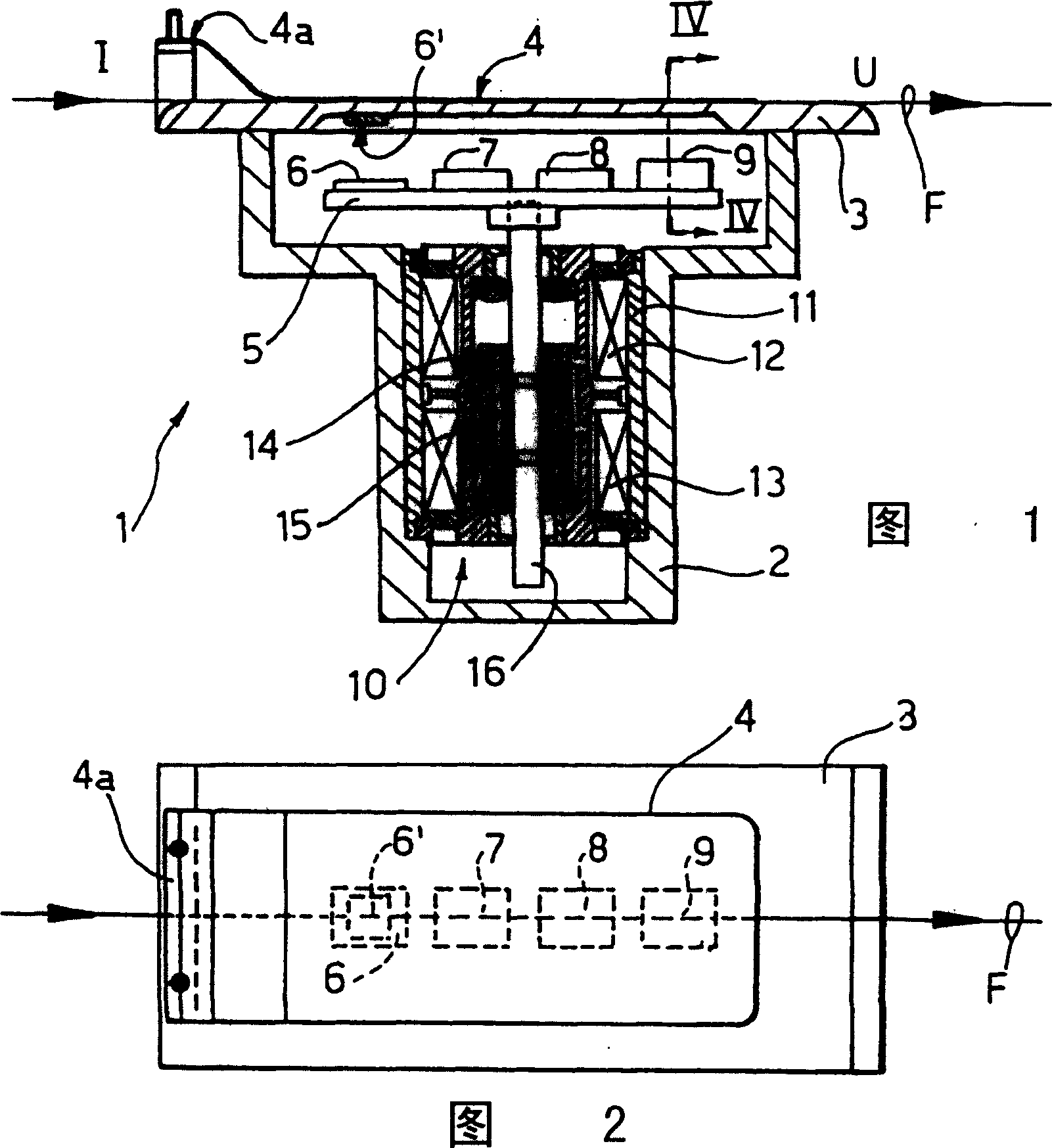

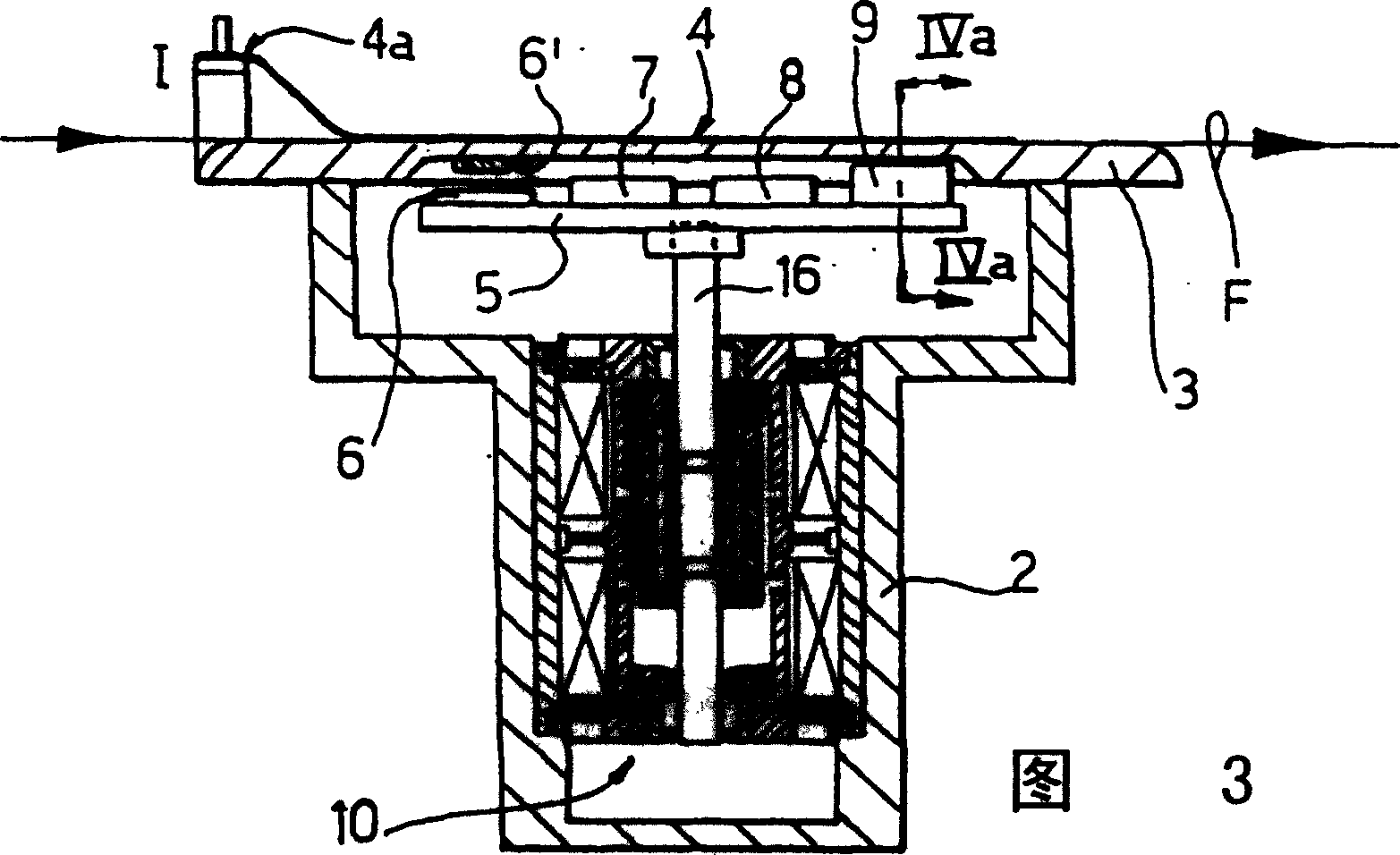

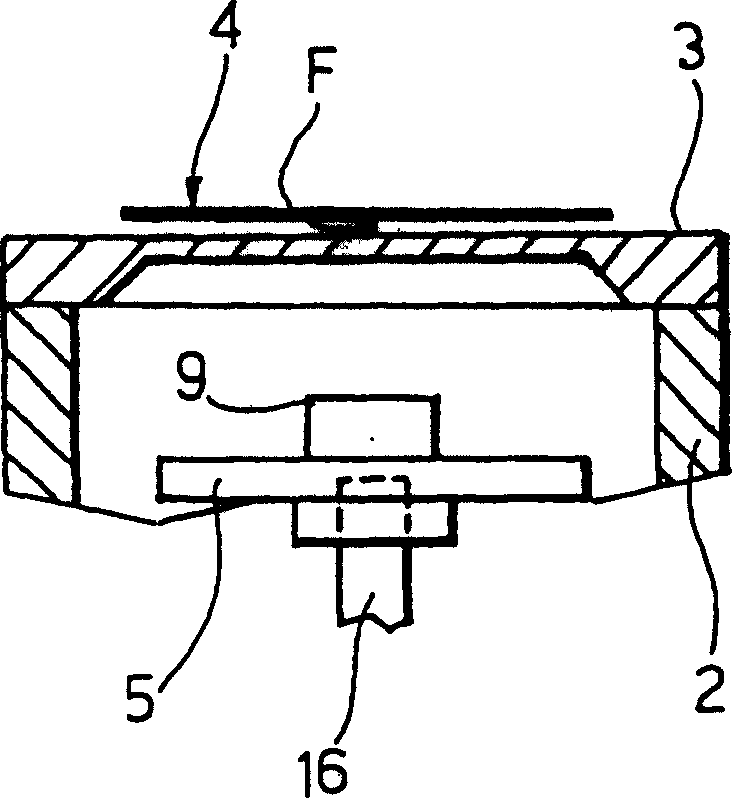

[0028] See Figure 1 to Figure 4 , Reference numeral 1 generally designates a weft thread brake which essentially comprises a hollow body 2 with a flat rigid top plate 3 rigidly connected to the body 2 at its end. The top plate 3 is made of a non-magnetic material such as aluminum and supports a resilient sheet 4 made of a magnetic material such as resilient steel. The foil 4 preferably has an end 4a rigidly connected to the top plate 3, the other end of which is free to move, between which the weft thread F, subject to a regulated braking action, slides. Generally, the connecting end 4a of the sheet 4 is placed at the entrance of the brake, and the end of the mountain is placed at the outlet U of the brake.

[0029] To produce an adjustable braking action, a yoke 5 which is movable linearly and supports a plurality of permanent magnets 6, 7, 8 and 9 is placed under the fixed plate 3 so that the magnets generate magnetic lines of force which pass through the fixed plate and C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com