Beam-pumping unit

A technology of pumping unit and pumping mechanism, which is applied in the direction of mechanical equipment, machine/engine, liquid displacement machinery, etc., and can solve the problems of small reciprocating stroke of sucker rod, high manufacturing and operating costs, and low oil pumping efficiency , to achieve the effect of improving oil pumping rate, low operating cost and saving electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

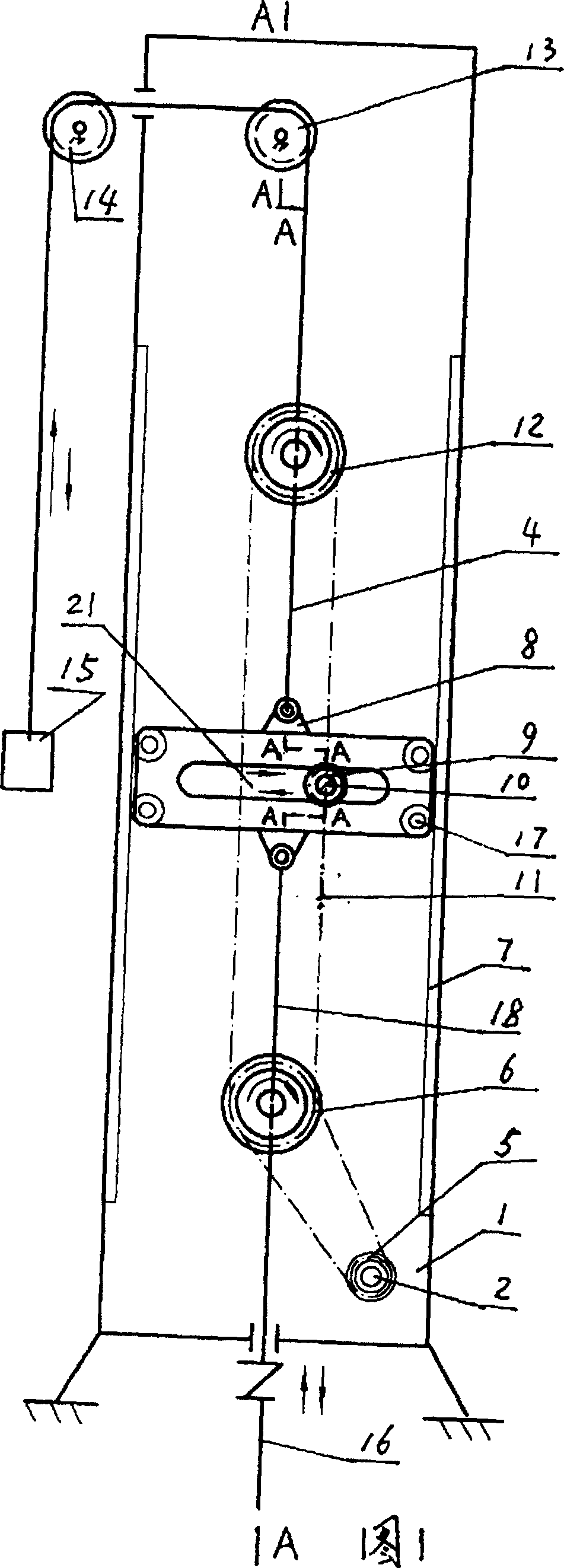

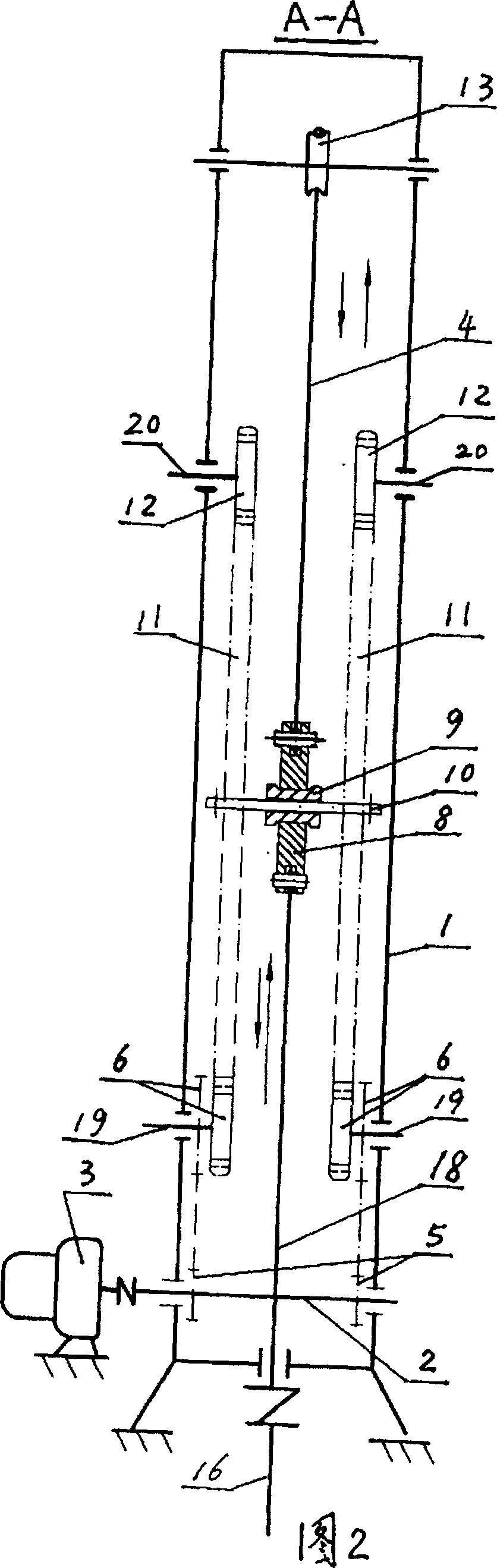

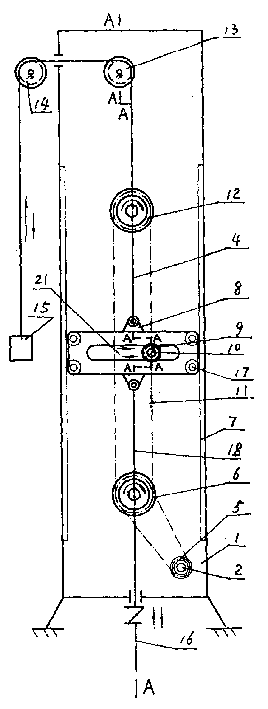

[0012] Hereinafter, the present invention will be further described by using the drawings and embodiments.

[0013] 1 and 2, the pumping unit has a frame 1, a reciprocating lifting mechanism and a driving device. The frame 1 has a quadrilateral frame structure. The reciprocating lifting pumping mechanism consists of guide slides 7 arranged on the two side walls of the frame 1, and the directional slide 8 is hinged to two guide wheels 17 respectively. The guide wheels 17 of the directional slide 8 are matched with the guide slide 7, and The frame 1 is provided with pulleys 13 and 14, the upper end of the directional slide 8 is connected with a steel cable 4, the upper steel cable 4 contacts the pulleys 13, 14 and is connected with the counterweight 15, and the lower end of the directional slide 8 is connected with a steel cable 18, The steel cable 18 at the lower end is connected to the sucker rod 16. The driving device consists of a drive shaft 2 connected to the electric reducer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com