Tea polyphenols extracting process

An extraction method and technology of tea polyphenols, applied in the field of tea polyphenols extraction, can solve the problems of lack of maturity and reliability of fluid extraction method, cumbersome process of resin adsorption method, low yield of ion precipitation method, etc., and achieve reduction in dosage , Low caffeine content, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

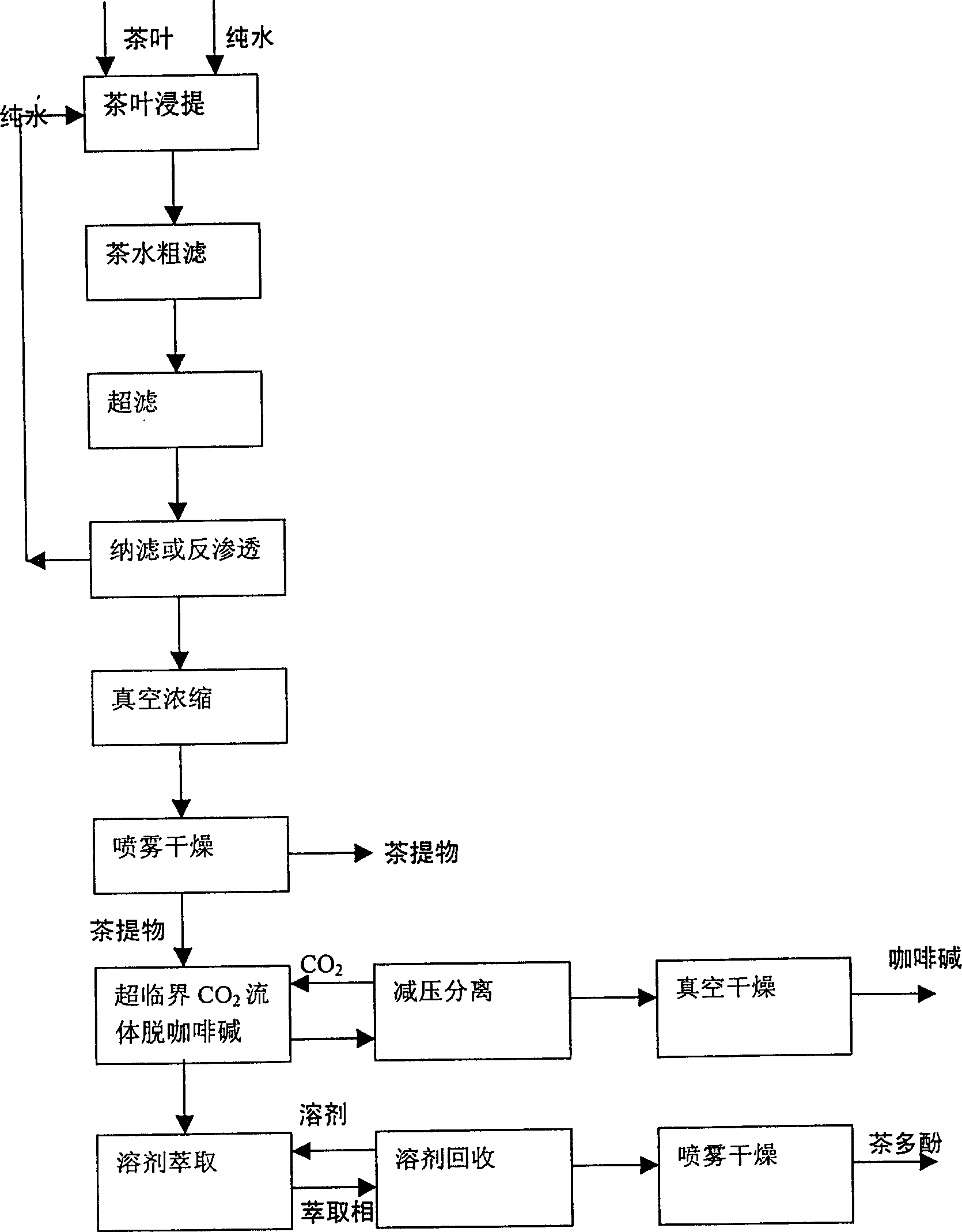

[0015] figure 1 In the process, weigh 2000 grams of medium and low-grade green tea or tea powder, add 20 liters of hot water at 90°C, stir and extract at a constant temperature for 30 minutes, filter to remove tea dregs, and cool the tea water to below 40°C. Repeat the leaching once, combine the two leaching teas and filter through a 120-mesh filter cloth to obtain 36.2 liters of tea, remove pectin with an ultrafiltration membrane with a cut-off molecular weight of 50,000 to 80,000, and dehydrate and concentrate with a reverse osmosis membrane with a cut-off molecular weight of 500,000 to 1,000,000 Obtain 3.6 liters of strong tea water, get 320.8 grams of powdered tea extract through spray drying, put the powdered tea extract into a supercritical extractor with a volume of 5 liters and pass into aqueous CO 2 While raising the temperature to 50°C, pressurize to 25-30Mpa, extract statically for 60 minutes, and open the pressure reducing valve to make the CO2 containing caffeine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com