Ultrasonic-wave ozone vehicle washing method and device

An ultrasonic and ozone technology, applied in cleaning methods and appliances, chemical instruments and methods, cleaning methods using liquids, etc., can solve the problems of inability to meet the needs of sterilization and disinfection inside the car body, environmental pollution of detergents, and high requirements for use conditions , to achieve the effect of low labor intensity, less washing time and low cost of car washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

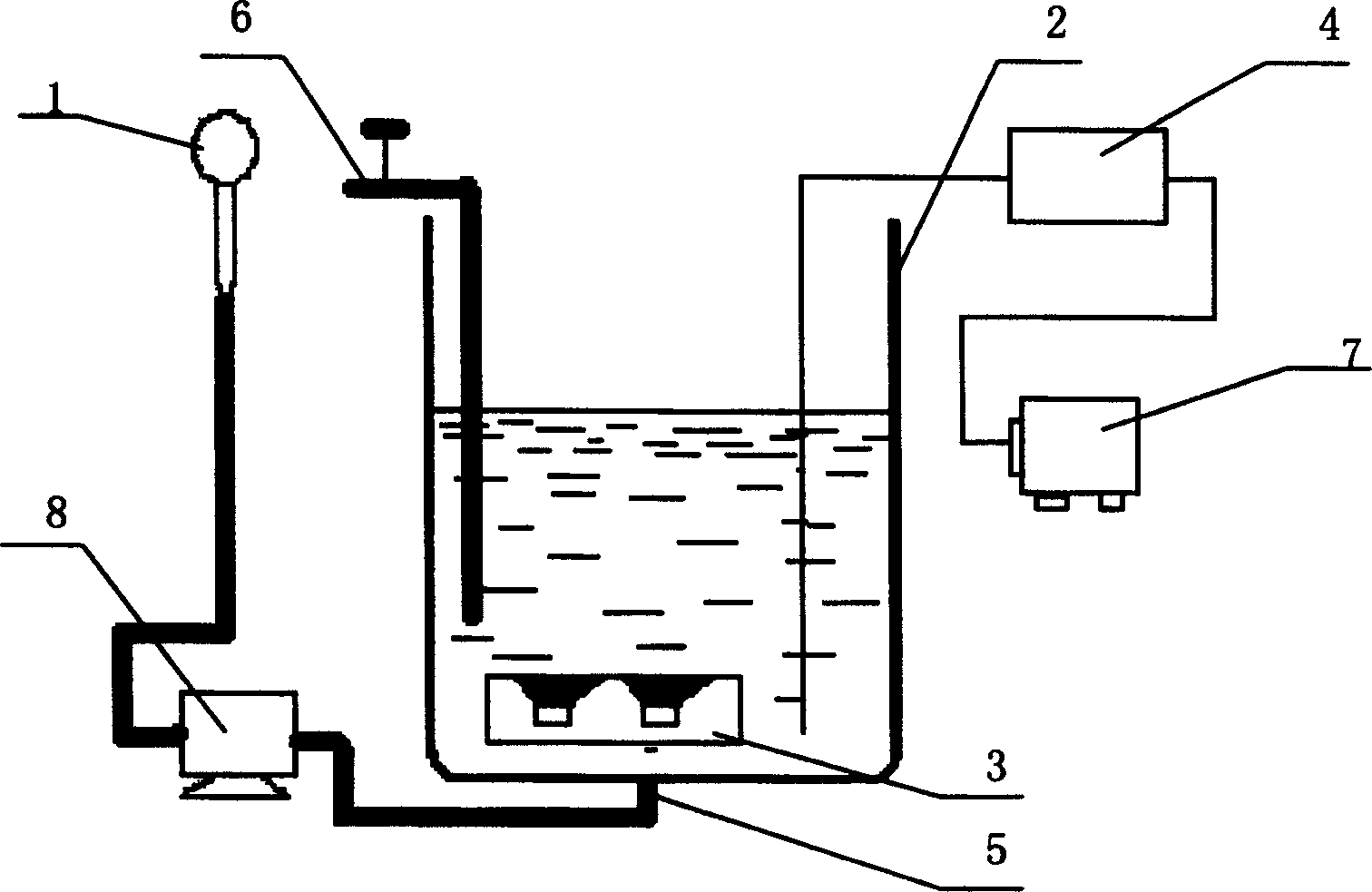

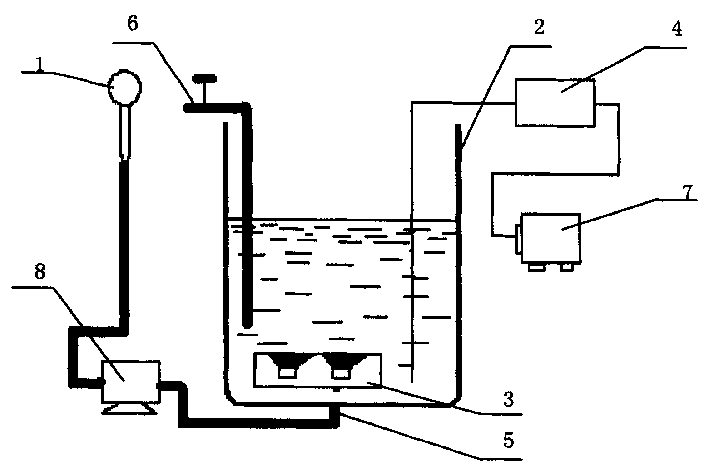

[0029] Such as figure 1 As shown, the device of the present invention is mainly composed of a car wash brush 1, a water-filled cylinder 2, an ultrasonic transducer 3 installed in the cylinder, and an ozone generator 4. The cylinder is provided with a water outlet pipe 5 and a water inlet pipe 6; The device is connected to the air pump 7, and the water outlet pipe 6 is connected to the booster pump 8. The model of each component is as follows

[0030] Cylinder: volume 20 liters;

[0031] Air pump: AC0-318, AC 220V, power 45W, displacement 50L / min, air pressure (0.06MPa) 1.5MPa;

[0032] Booster pump: 15WG0.8-15 single-phase motor. Voltage 220, head 15 meters, power 80W;

[0033] Ozone generator: AC 220V, power 25W;

[0034] Ultrasonic water flow car wash brush: the ordinary car wash brush is equipped with a 30-35Khz mechanical jet ultrasonic generator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com