Metal pile head

A metal and pile head technology is applied in the field of special metal pile heads for expanding bottom piles to form piles, which can solve the problems such as the inability to remove the mud at the bottom of the pile and the settlement of the pile, and achieve a low ratio of single pile bearing capacity, low single pile cost, Simple effect of piling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

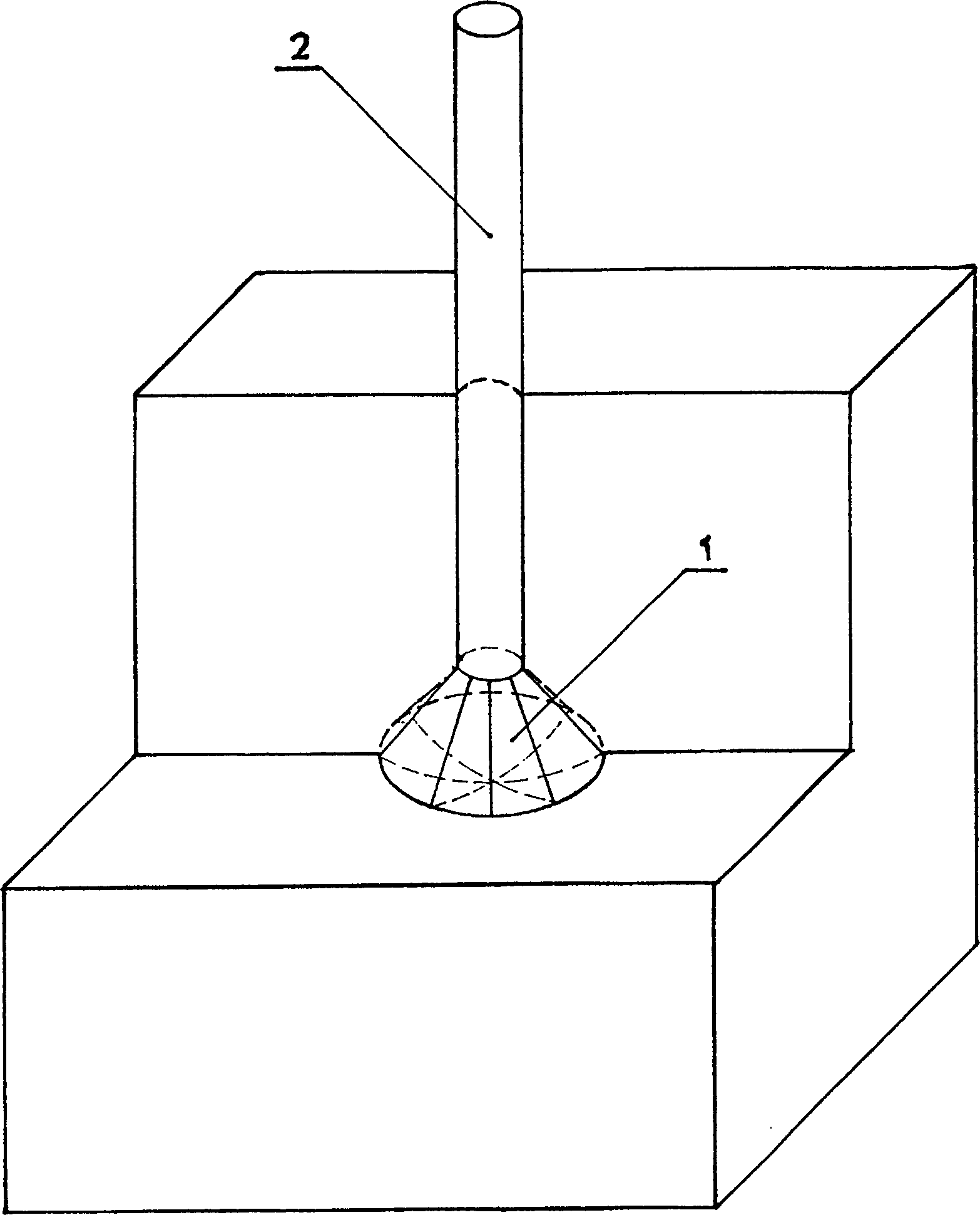

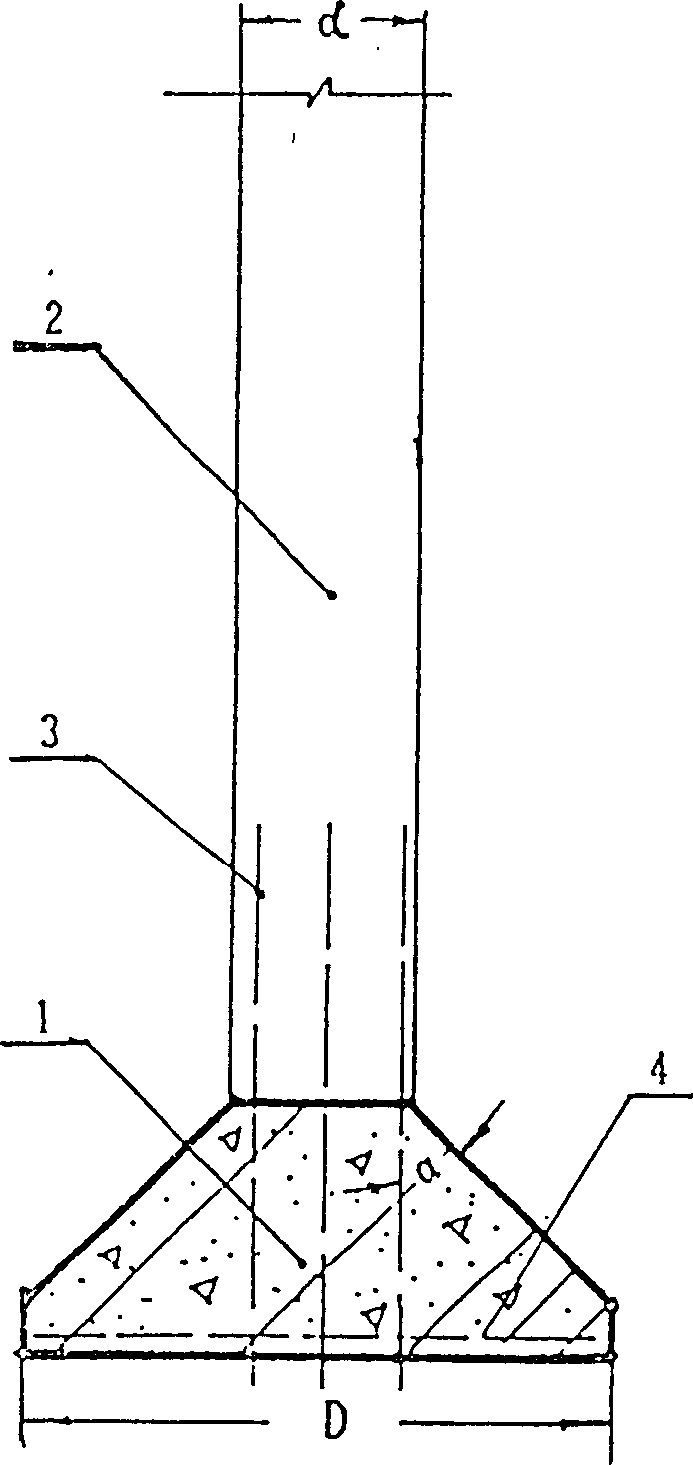

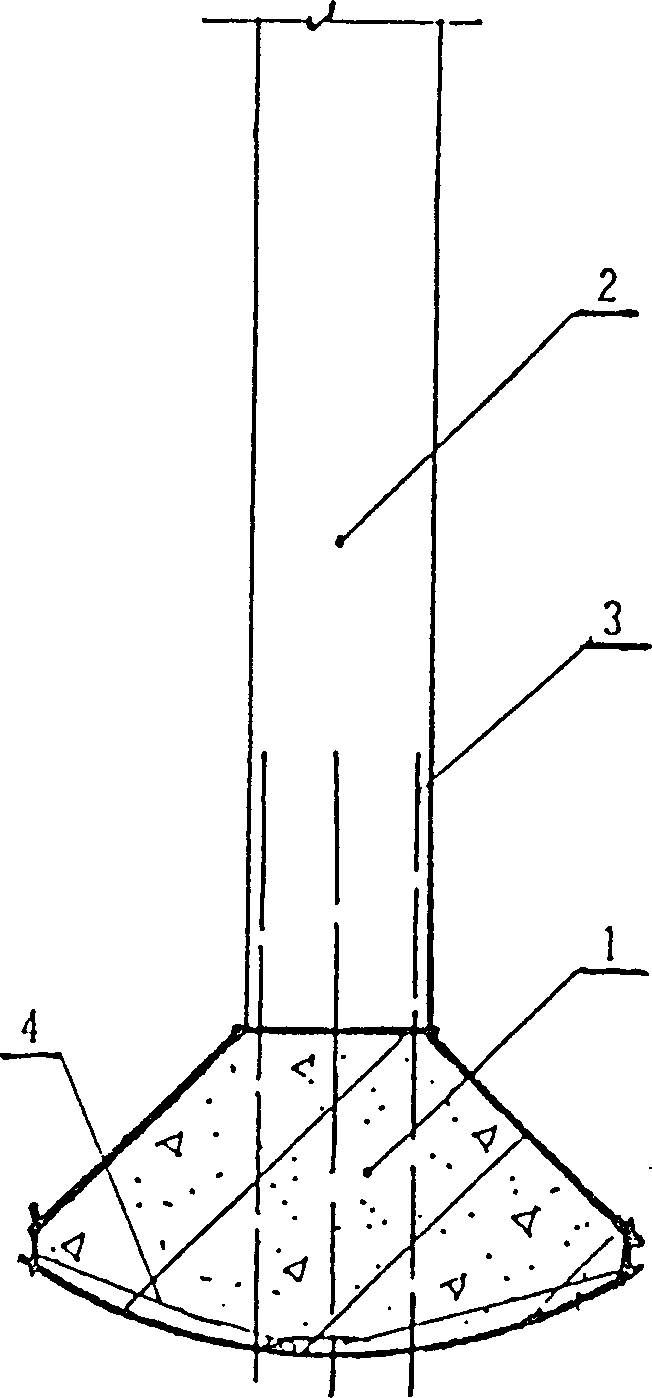

[0038] Such as Figure 1-4 As shown, the immersed tube prefabricated steel concrete expanded bottom pile is composed of a prefabricated pile body 2 and a cast-in-place steel concrete base 1, and the pile body 2 is docked with the base 1 by using the inserted rib 3 at the bottom in the hard soil layer under the positioning of the immersed tube Anchored to form a whole.

[0039] The diameter of the largest part of the base 1 should be greater than the diameter of the pile body 2. Optimally, the cross-sectional diameter d of the pile body 2 is 250-700 mm, and the ratio of the diameter D to d of the largest cross-sectional part of the base 1 is generally 1.5

[0040] The specific shape of the cast-in-place reinforced concrete base 1 is not limited, but tests have shown that if Figure 2~4 The three classes of shapes shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com