Preparation method of edible fungus extracting solution, edible fungus extracting solution, and compound prepared from edible fungus extracting solution

A technology for edible fungi and extracts, applied in food extraction, food science, applications, etc., can solve problems such as reduced efficacy and inactivation of heat-sensitive components, to improve utilization, increase nutrients, and ensure clarity and stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

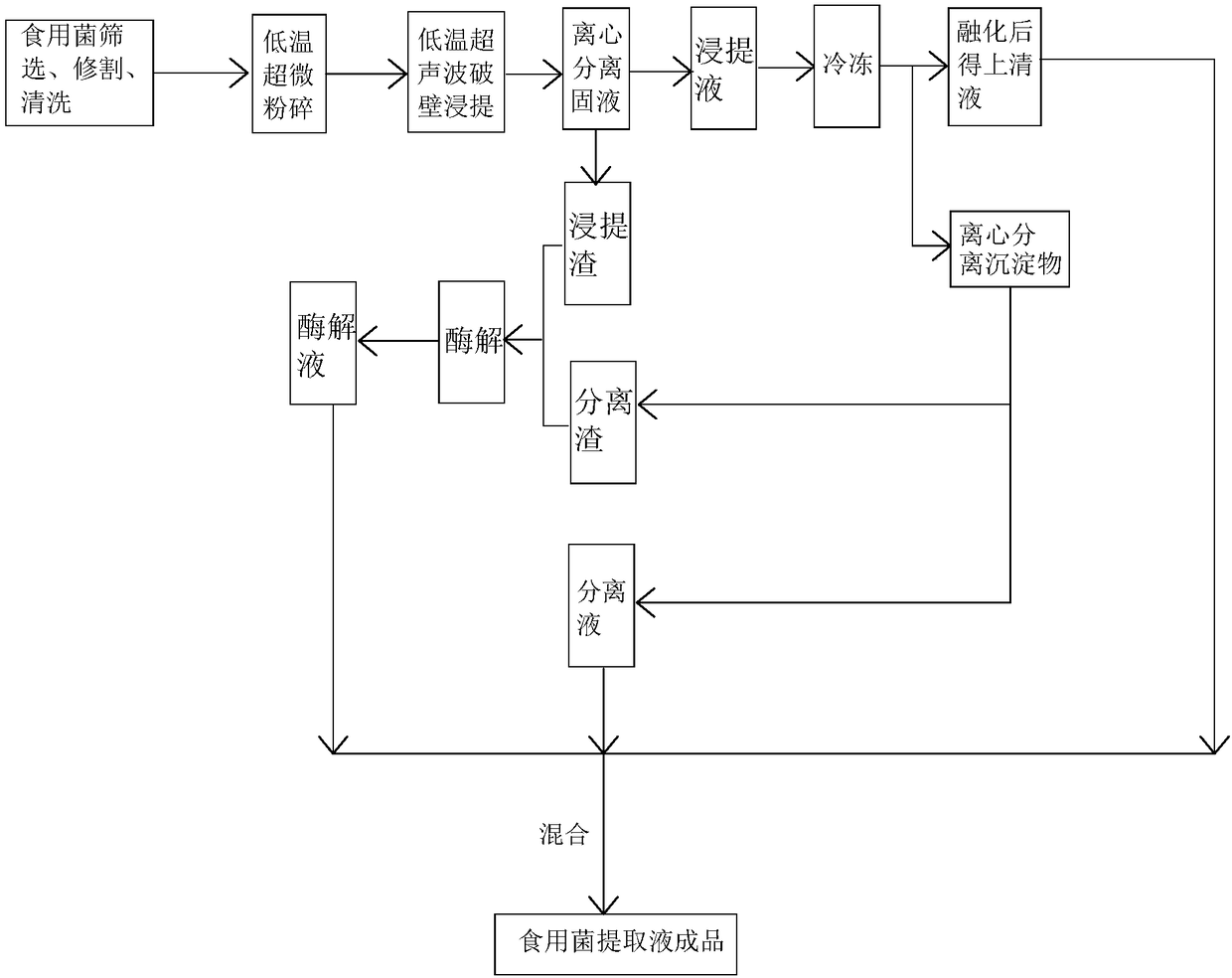

Image

Examples

Embodiment 1

[0035] Embodiment 1: The preparation method of the edible fungus extract, the edible fungus fruiting body is successively subjected to low-temperature ultrafine pulverization, low-temperature ultrasonic leaching, liquid freezing separation, and solid enzymatic treatment to obtain the edible fungus extract, which specifically includes the following steps: (1) screening of raw materials; (2) low-temperature ultrafine grinding; (3) low-temperature ultrasonic extraction; (4) centrifugal separation; (5) liquid freezing separation; (6) solid enzymatic hydrolysis; (7) vacuum concentration to obtain edible Bacteria extract; Among them,

[0036] (1) Raw material screening: remove deformed and insect-bitten individuals, screen clean and round qualified edible fungus fruiting bodies, rinse and dry for later use;

[0037] (2) Low-temperature ultrafine grinding: the fruiting bodies of the screened edible fungi are subjected to low-temperature ultrafine grinding with a low-temperature ultra...

Embodiment 2

[0051] Embodiment 2: The preparation method of the edible fungus extract, the edible fungus fruiting body is successively subjected to low-temperature ultrafine pulverization, low-temperature ultrasonic extraction, liquid freezing separation, and solid enzymatic treatment to obtain the edible fungus extract, which specifically includes the following steps: (1) screening of raw materials; (2) low-temperature ultrafine grinding; (3) low-temperature ultrasonic extraction; (4) centrifugal separation; (5) liquid freezing separation; (6) solid enzymatic hydrolysis; (7) vacuum concentration to obtain edible Bacteria extract; Among them,

[0052] (1) Raw material screening: remove deformed and insect-bitten individuals, screen clean and round qualified edible fungus fruiting bodies, rinse and dry for later use;

[0053] (2) Low-temperature ultrafine grinding: the fruiting bodies of the screened edible fungi are subjected to low-temperature ultrafine grinding by a low-temperature ultra...

Embodiment 3

[0067] Embodiment 3: The preparation method of the edible fungus extract, the edible fungus fruiting body is successively subjected to low-temperature ultrafine pulverization, low-temperature ultrasonic extraction, liquid freezing separation, and solid enzymatic treatment to obtain the edible fungus extract, which specifically includes the following steps: (1) screening of raw materials; (2) low-temperature ultrafine grinding; (3) low-temperature ultrasonic extraction; (4) centrifugal separation; (5) liquid freezing separation; (6) solid enzymatic hydrolysis; (7) vacuum concentration to obtain edible Bacteria extract; Among them,

[0068] (1) Raw material screening: remove deformed and insect-bitten individuals, screen clean and round qualified edible fungus fruiting bodies, rinse and dry for later use;

[0069] (2) Low-temperature ultrafine grinding: the fruiting bodies of the screened edible fungi are subjected to low-temperature ultrafine grinding with a low-temperature ult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com