Bearing member for CD drive machine core

A technology for carrying components and optical drives, applied in the direction of record carrier structural parts, instruments, data recording, etc., can solve problems such as reduced efficiency, increased component costs, and increased man-hours for optical drive assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

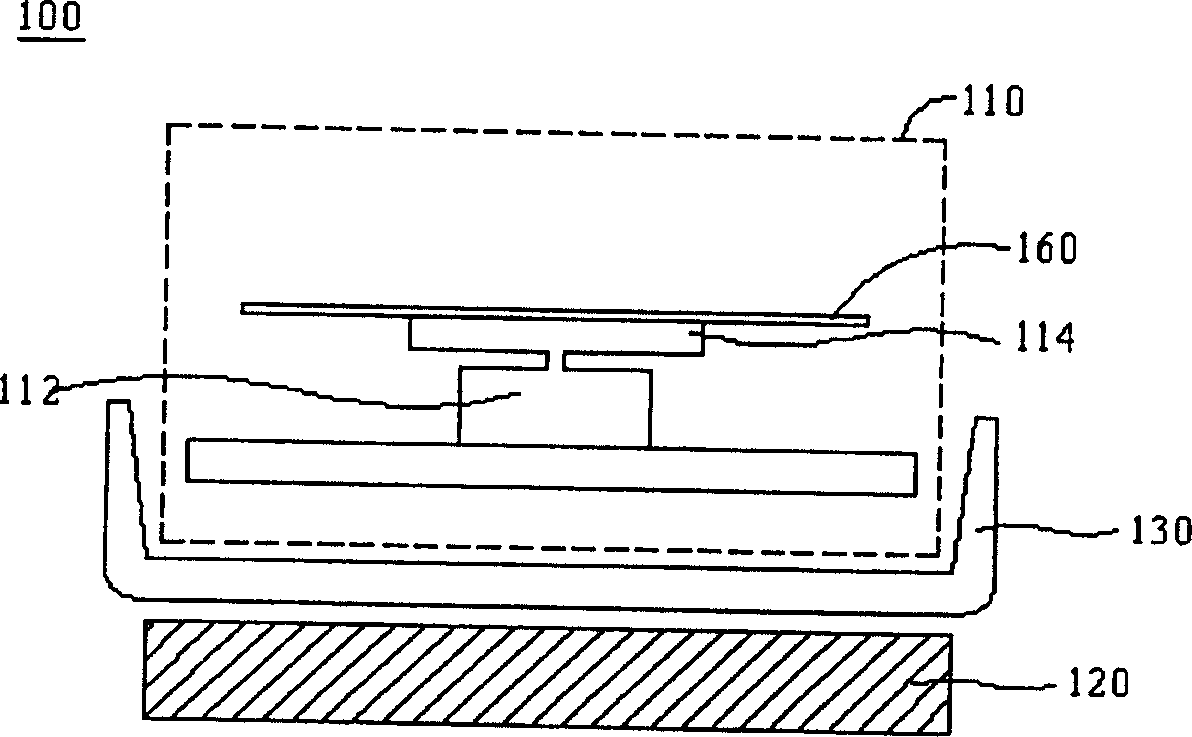

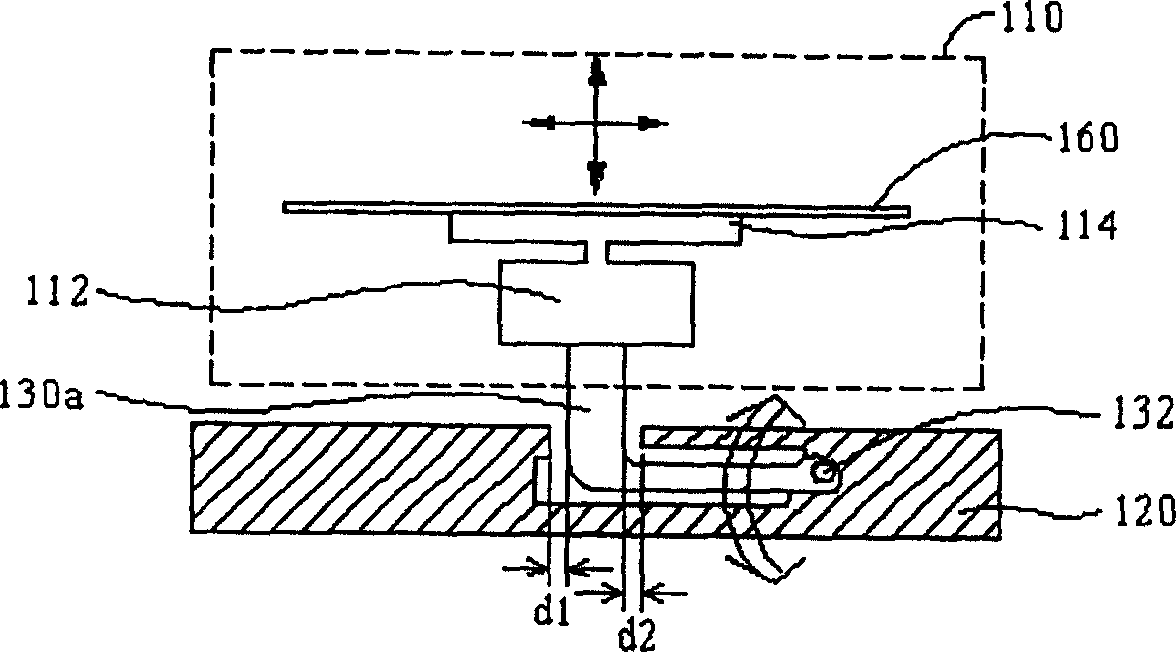

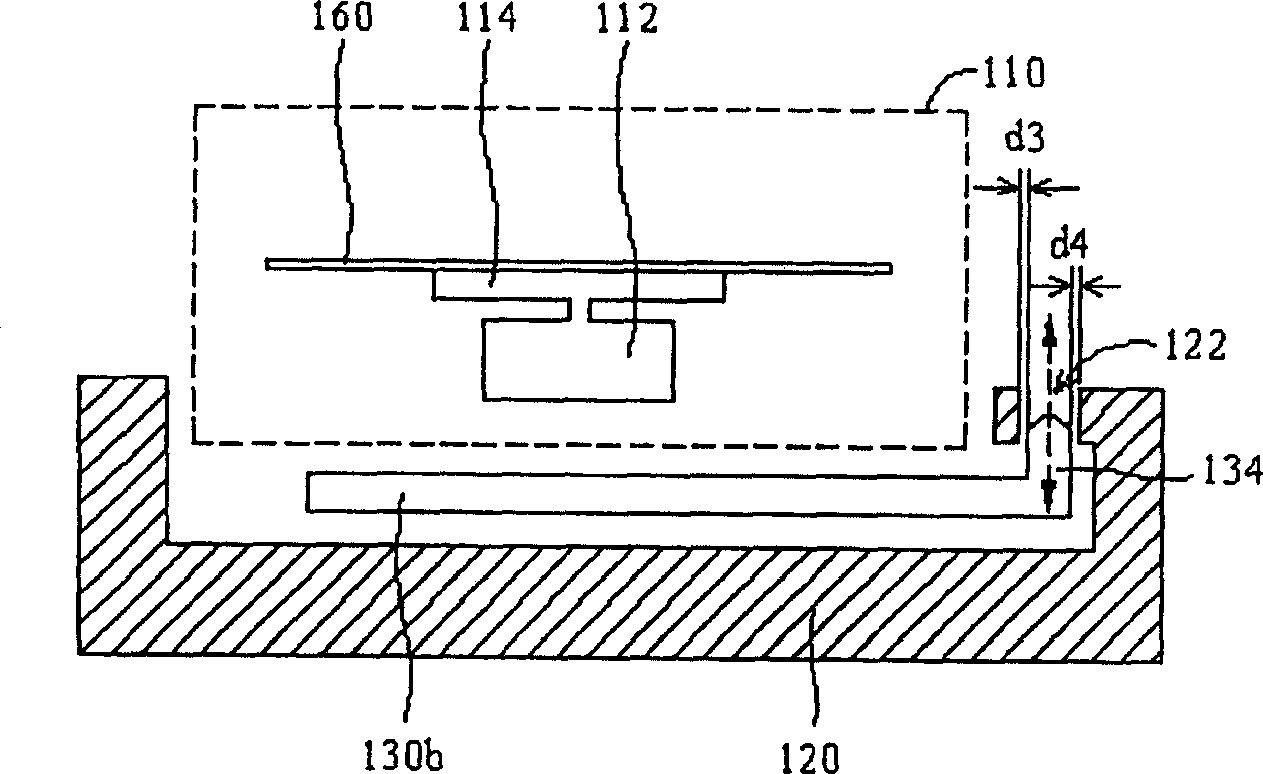

[0021] See Figure 4 , illustrating the structure of an optical drive carrying an optical disc according to an embodiment of the present invention. The mechanism of the optical drive 1 carrying the optical disc 60 of the present invention is similar to the existing structure, including the organic core 10 , the base 20 and the carrying member 30 . Wherein, the movement 10 has a motor 12 for rotating the optical disc 60 and a turn table 14 for carrying the optical disc 60 . The base 20 serves as the basic structure of the optical drive 1, and has an elastic portion 22 and a guide portion (not shown), wherein the guide portion can be as follows: Figure 2b The guide chute 122 in the prior art structure shown.

[0022] In addition, the carrying member 30 is movably connected to the base 20 for carrying the movement 10 . The bearing member 30 of this embodiment can be referred to Figure 5a As shown, it is a swing bearing member, which has a guided part (such as a chute) corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com