Magnetic valve type controllable electric reactor

A reactor and magnetic valve type technology, applied in the field of magnetic valve type controllable reactors, can solve the problems of poor reactor adjustment linearity, difficulty in reducing manufacturing costs, and difficult assembly, etc., to achieve good adjustment linearity and balance Smoothness and ease of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

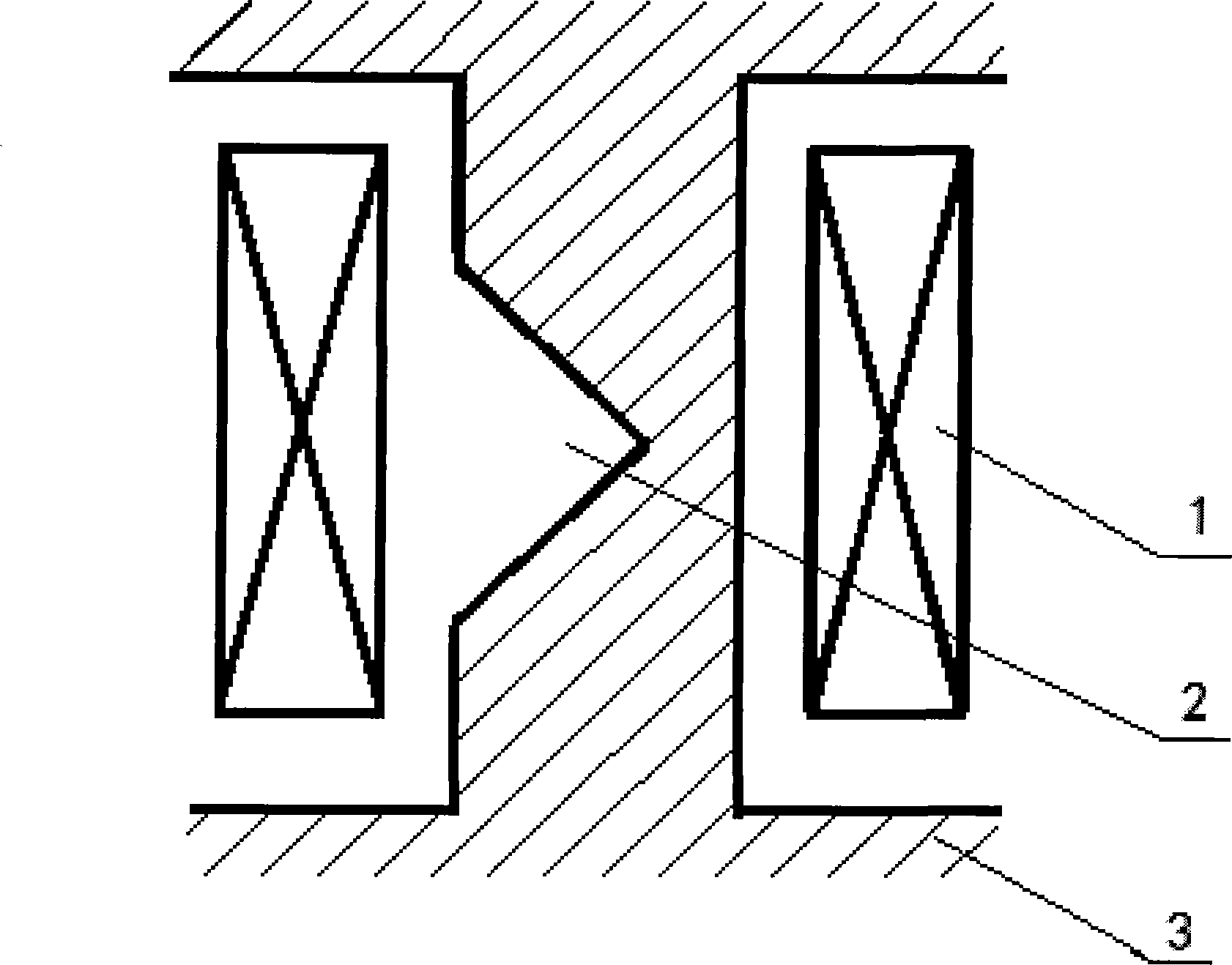

[0011] see figure 1 , the composition of the magnetic valve type controllable reactor is as follows: the iron core 3 made of silicon steel sheets has a gap of the magnetic valve 2, and the cross section of the iron core 3 at the gap of the magnetic valve 2 is V-shaped; wherein, the V-shaped magnetic valve 2 The angle between the two slopes of the notch is 90 (can be 70-150) degrees, and the notch of the V-shaped magnetic valve 2 is located on one side of the iron core 3 . The iron core 3 is externally provided with a coil 1 matched therewith.

[0012] When in use, by adjusting the current in the coil 1, the reactor output with uniform saturation of the iron core can be obtained, and the required linearly changing reactor output can be obtained.

[0013] Apparently, those skilled in the art can make various changes and modifications to the magnetic valve type controllable reactor of the present invention without departing from the spirit and scope of the present invention. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com