Multi-stage pulse combustion control system and method

A technology of pulse combustion and control method, which is applied in the direction of combustion method, combustion control, and fuel supply adjustment, etc., can solve the problems of limited adjustment ratio, insufficient fuel combustion, uneven heating of workpieces, etc., to improve product quality and adjust linearity. The effect of good temperature and smooth combustion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

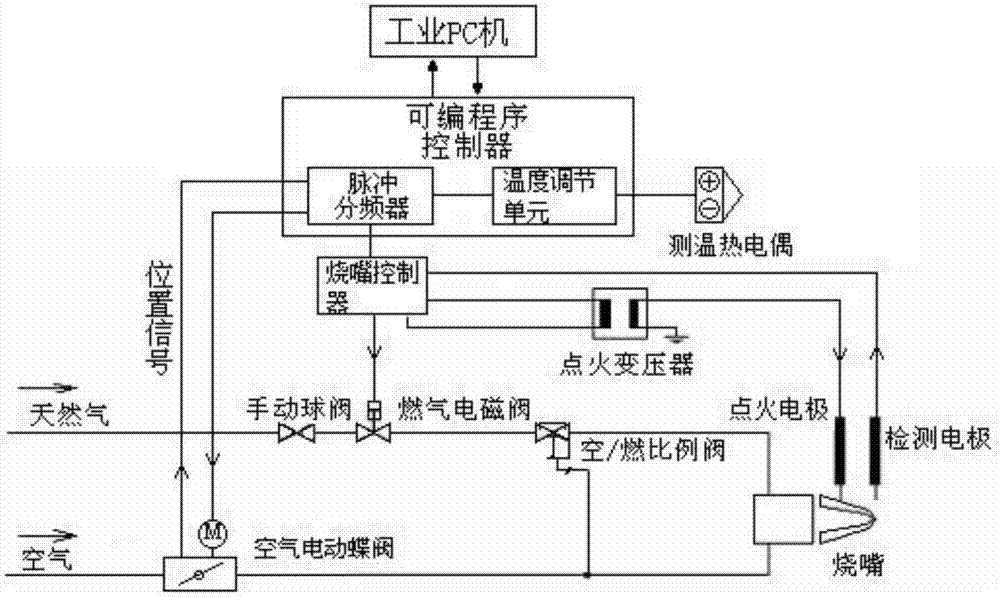

[0032] On the one hand, the present invention provides a multi-stage pulse combustion control system, including: temperature measuring thermocouple, programmable controller, burner controller, air electric butterfly valve, gas solenoid valve, air / fuel proportional valve, ignition transformer , burner; the programmable controller is respectively connected with the temperature measuring thermocouple, the input end of the burner controller, and the air electric butterfly valve on the air pipeline, and the output end of the described burner controller is respectively connected with the gas on the gas pipeline. The solenoid valve, ignition transformer, and burner are connected. The burner is connected with the burner controller through the detection electrode. The burner is connected with the ignition transformer through the ignition electrode. The air / fuel ratio valve is connected with the air electric butterfly valve. , Gas solenoid valve and burner are connected.

[0033] The pr...

Embodiment 2

[0040] On the one hand, the present invention provides a multi-stage pulse combustion control system, including: temperature measuring thermocouple, programmable controller, burner controller, air electric butterfly valve, gas solenoid valve, air / fuel proportional valve, ignition transformer , burner, industrial PC; the programmable controller is respectively connected with the temperature measuring thermocouple, the input end of the burner controller, and the air electric butterfly valve on the air pipeline, and the output end of the burner controller is respectively connected with the gas The gas solenoid valve on the pipeline, the ignition transformer, and the burner are connected. The burner is connected to the burner controller through the detection electrode. The burner is connected to the ignition transformer through the ignition electrode. The air / fuel ratio valve is respectively It is connected with air electric butterfly valve, gas solenoid valve and burner, and the p...

Embodiment 3

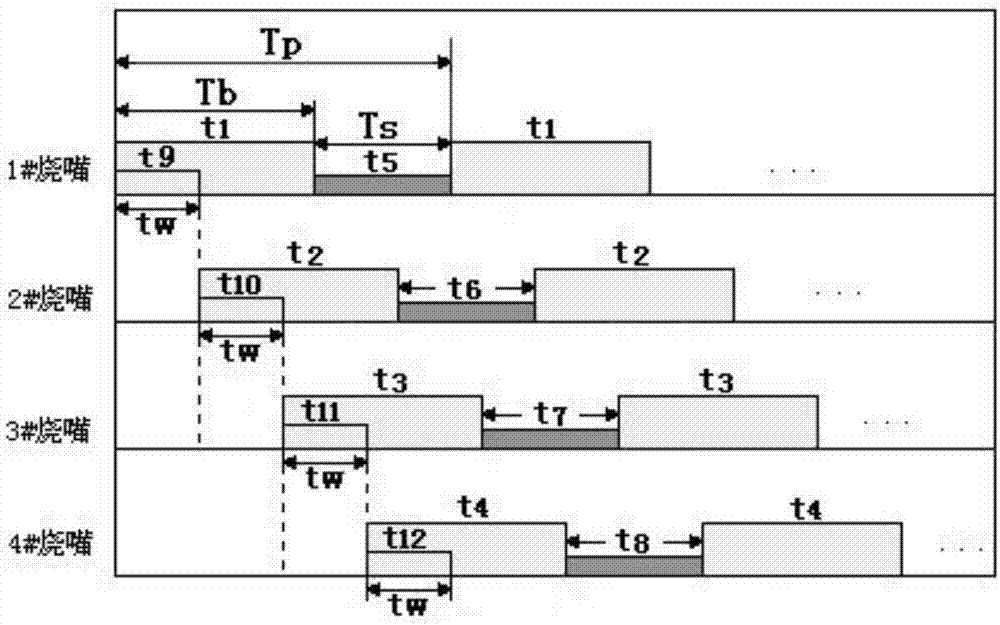

[0060] This embodiment is used as an example of the pulse frequency division method of the pulse frequency divider in Embodiment 2, please refer to figure 2 :

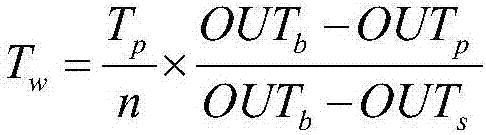

[0061] Taking the multi-segment pulse frequency division process of four burners in a certain temperature control section of a kiln as an example, the working process is clarified. T p , T b , T s They are the pulse combustion cycle, the burner high fire working cycle, and the burner low fire working cycle; the four burners are delayed in sequence according to a certain time, t w Delay the start time for each burner, that is, the delay time of the current start burner relative to the previous burner. T p , T b , T s ,t w Adjustable by industrial PC, t 1 -t 4 It is a timer used to control the fire of four burners, and the timing time is T b ;t 5 -t 8 In order to control the four burner small fire working timers, the timing time T s ;t 9 -t 12 In order to control the delay start timer of each burner, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com