Process of electricity sedimentation in aqueous solution for producing rare earth magnetic film alloy material

An electrodeposition method and transition metal technology, applied in the field of rare earth permanent magnetic thin film alloy materials, can solve the problems that ultrafine powder cannot be in contact with air, cannot meet the production of permanent magnetic materials, and does not mention magnetic materials, etc. The effects of separation and film thickness control, easy composition and film thickness, and bright coating surface without cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: prepare Nd-Fe-B alloy

[0049] Plating solution: 0.08mol / L FeCl 2 +0.8mol / L Glycine+0.5mol / L NdCl 3 +0.8mol / LCaCl 2 +H 3 BO 3 0.5mol / L+additive II, wherein additive II is benzylamine 0.4g / L+H 3 BO 3 0.2g / L, pH=6.0, D=20mA / cm 2 , T=30℃

[0050] Coating composition: weight ratio Fe%=87.46, Nd=11.5%, B%=1.04

[0051] Coating test method: After dissolving the sample with 1:1 HCl, set it to 50ml, measure the content of Fe by atomic absorption method, measure the content of Nd and B respectively by spectrophotometry, heat-treat the obtained coating, and heat-treat the material The magnetic properties were measured with a vibrating sample magnetometer, and the results are shown in Figure 11 . It can be seen that the Bs of this material is 2×10 4 Gs. Br=Hc is 1600Oe, which is a permanent magnetic film material with excellent magnetic properties.

Embodiment 2

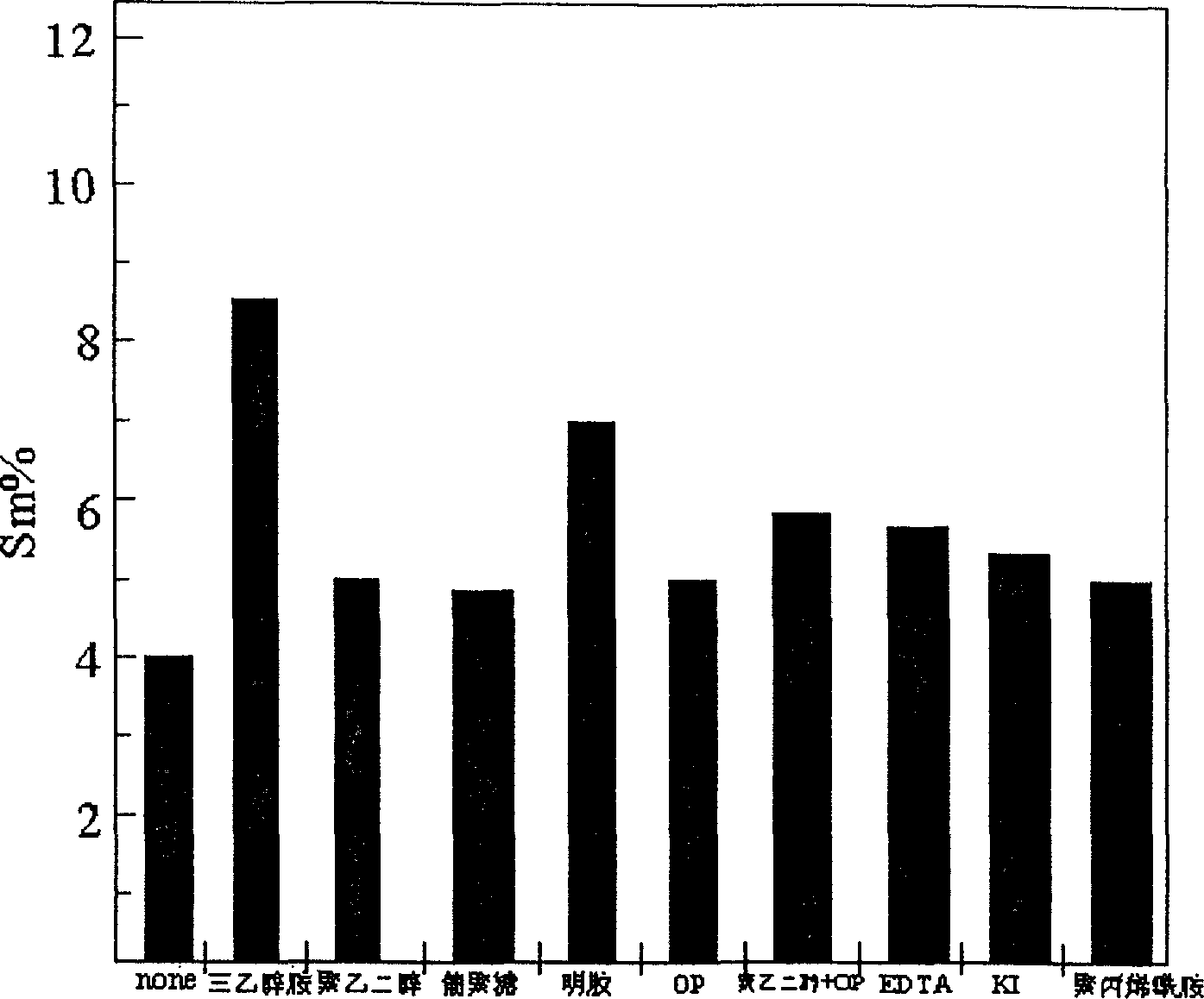

[0052] Embodiment 2: another group of electroplating solution components are, FeCl 2 (0.08mol / L)+Glycine(0.9mol / L)+CaCl 2 (0.8mol / L)+RE(0.5mol / L)+Additive I(0.2g / L)+Additive II+H 3 BO 3 (0.5mol / L); Wherein additive I is any one in polyethylene glycol 20000, dextran, gelatin, OP, EDTA, polyacrylamide, KI; Additive II is any in benzylamine, mannitol, ammoniacal liquor A (0.2g / L) and H 3 BO 3 (0.4g / L) mixed, or any one of dimethylaniline, benzylamine, methanol (0.4g / L) and NaBH 4 (0.2g / L) mixed.

Embodiment 3

[0053] Embodiment 3: technological process

[0054] ①Preparation of solution

[0055] Raw materials: rare earth oxide + hydrochloric acid or rare earth chloride, Fe powder + HCl or ferrous chloride, complexing agent, CaCl 2 , Additive I, H 3 BO 3 , Additive II.

[0056] The preparation process is as follows:

[0057] Solution A: After dissolving the rare earth oxide with hydrochloric acid, add some complexing agent.

[0058] Solution B: The transition metal chloride is dissolved and another part of the complexing agent is added.

[0059] Solution C: After mixing solution A and solution B, add CaCl 2 and H 3 BO 3 .

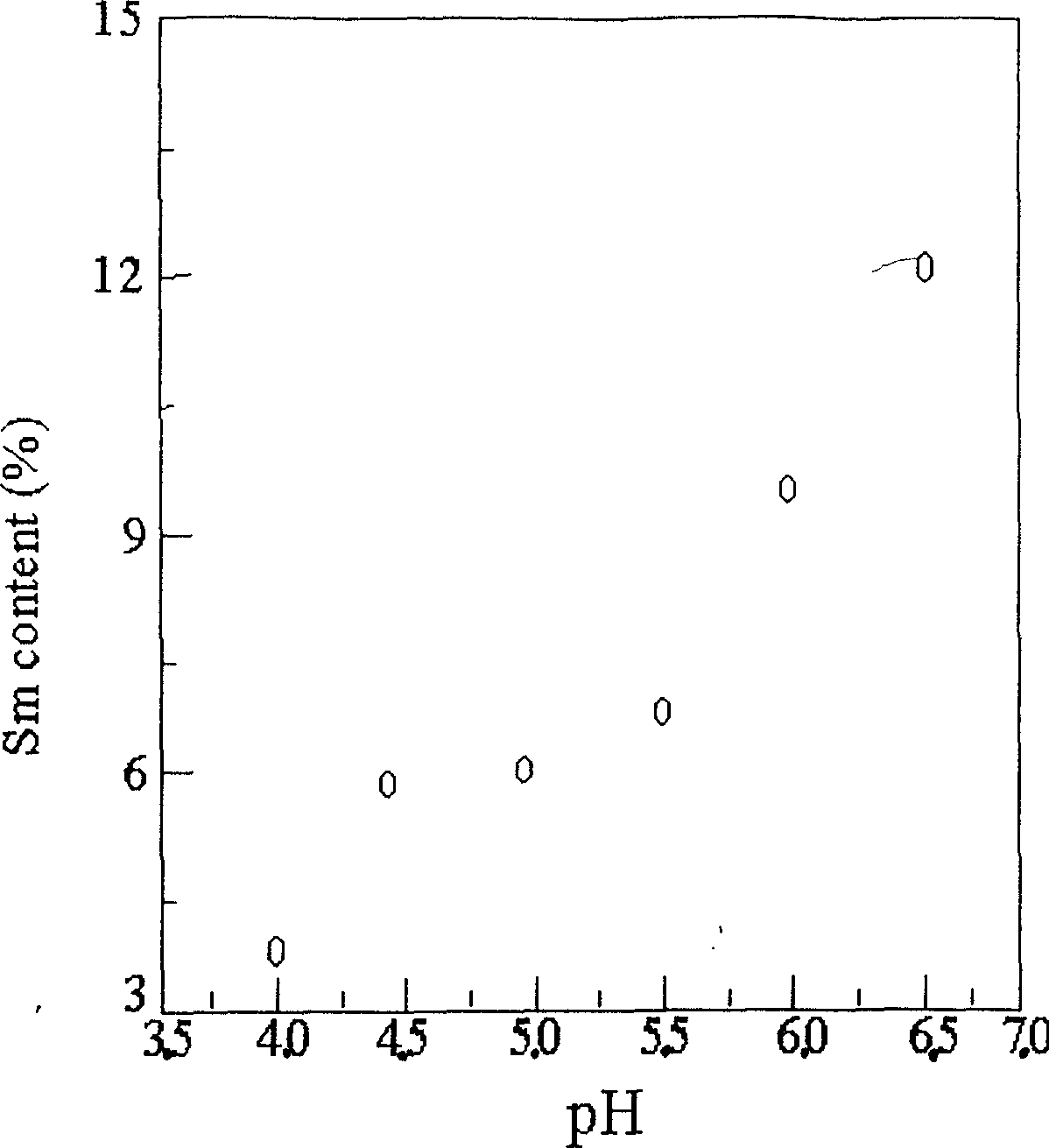

[0060] Adjust the pH value to 1-6.5

[0061] Solution D: Solution C + Additive I + Additive II.

[0062] Then adjust the pH to 1-6.5

[0063] ②Electrodeposition

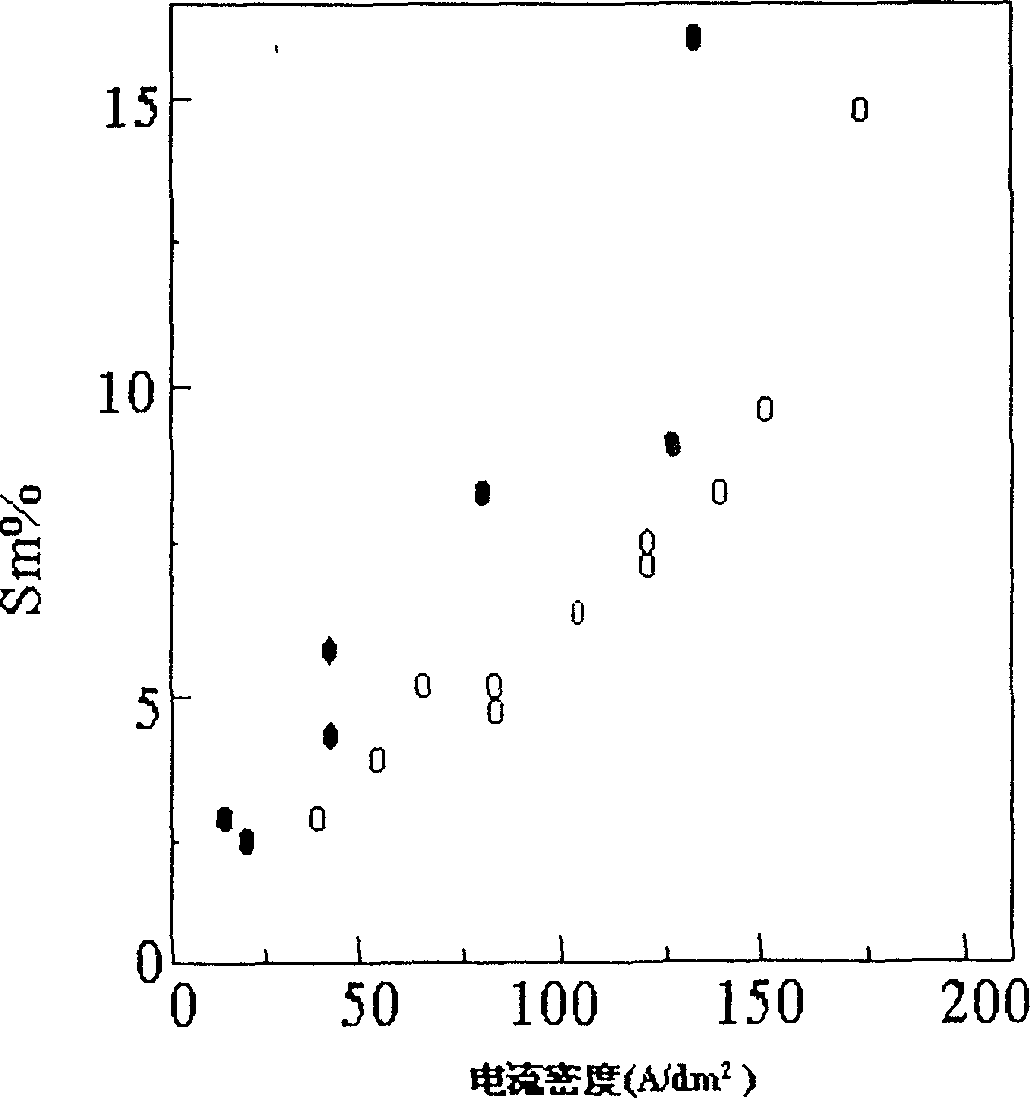

[0064] Electrode: The anode uses an inert anode, a transition metal anode or a double anode, and the anode is an electrodeposited substrate material.

[0065] Plating treatment:

[0066] Br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com