Method for calibrating industrial CT system detector by group series winding

A calibration method and detector technology, which can be used in digital differential analyzers, calculations using non-numerical representations, and material analysis using radiation. Increased computation time, good correction quality, and fewer iterations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

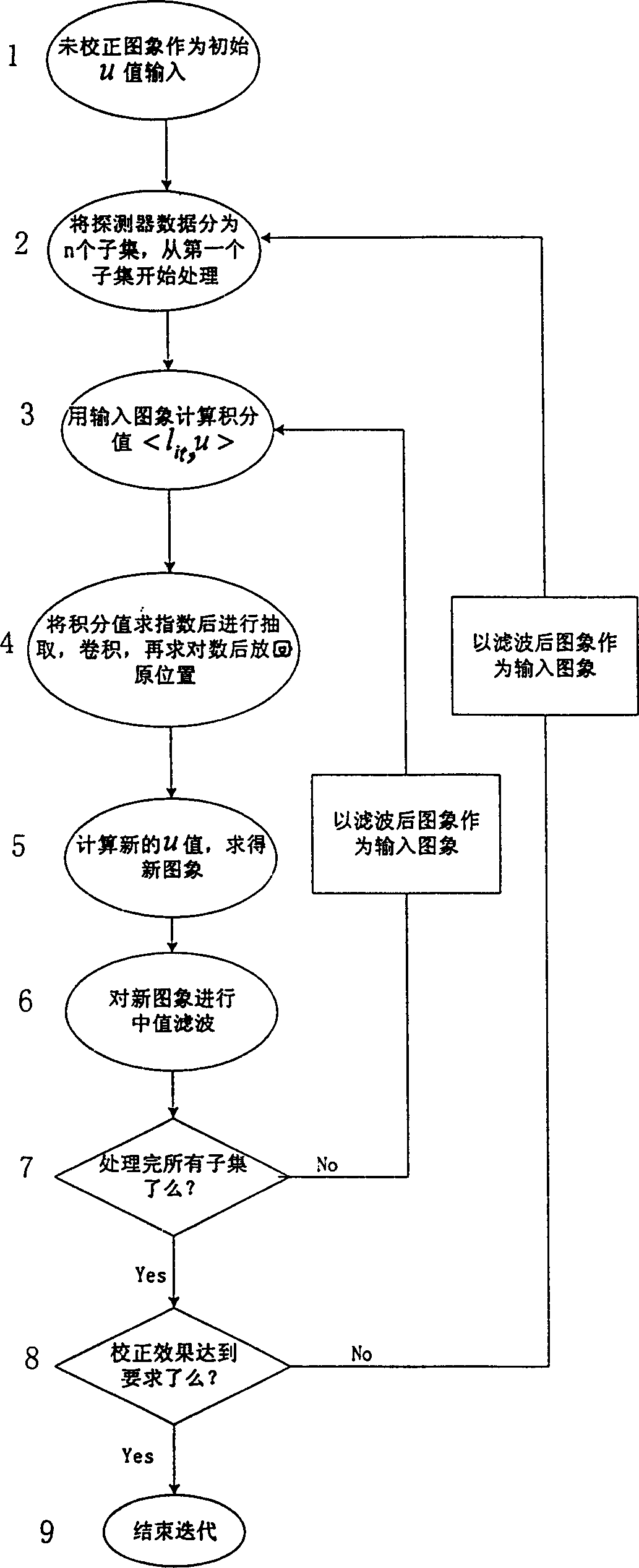

Method used

Image

Examples

Embodiment Construction

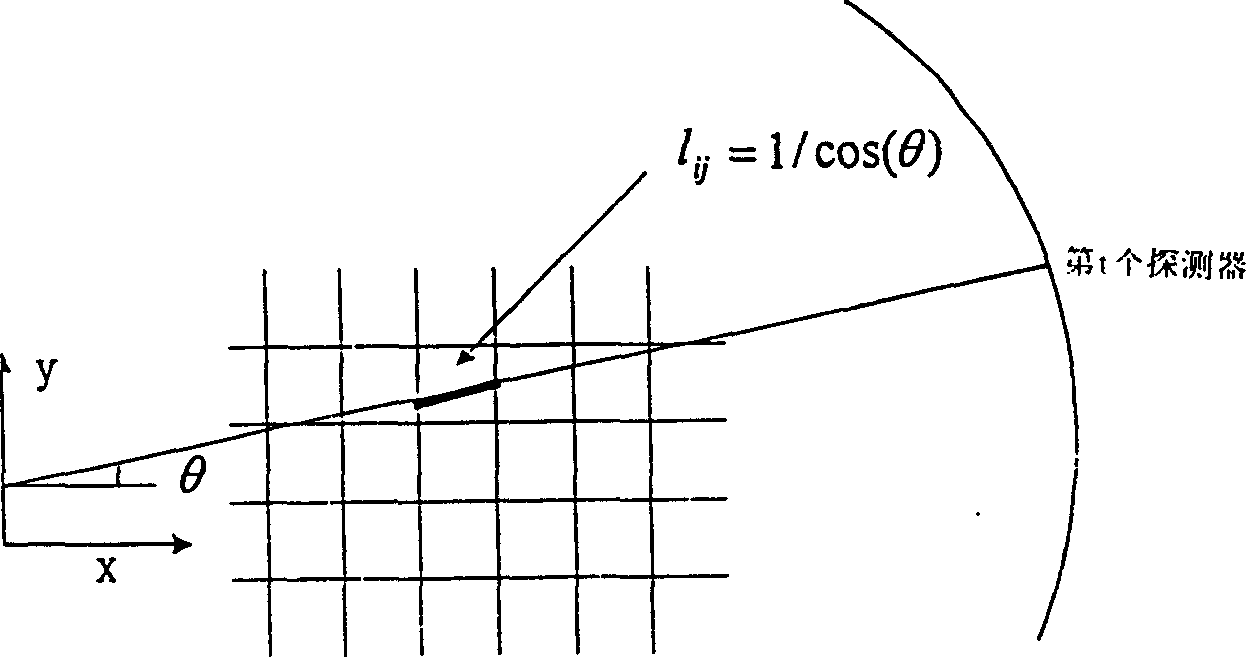

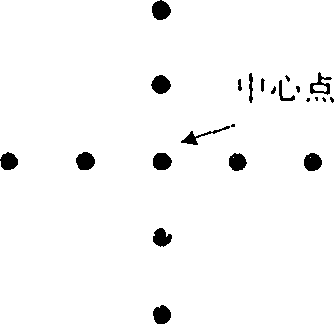

[0025] The specific method for calculating the integral value with the input image as described in step (3) in the technical solution is: set the number of subsets as s, and in a certain projection direction i, input the absorption coefficient Compute the integral value in each detector direction t l it , u n > = Σ j l itj u j n , where l itj is the intersecting length of pixel j in the direction of detector t when projecting direction i; t=1, 2, ..., k, k is a natural number, t is the number of detectors in each scan, and all integrals are calculated for t valueit , u n >, repeat the above step (3) for all i in the subset, and calculate all integral values it , u n >, i=(s-1)*r / n+1,...,s*r / n. The intersection length l itj can be a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com