Process for making flowering tree - garden landscape

It is a technique of making crafts and landscapes, which is applied in the field of architecture and gardens. It can solve the problems of simulated plastic trees without charm and achieve a wide range of effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

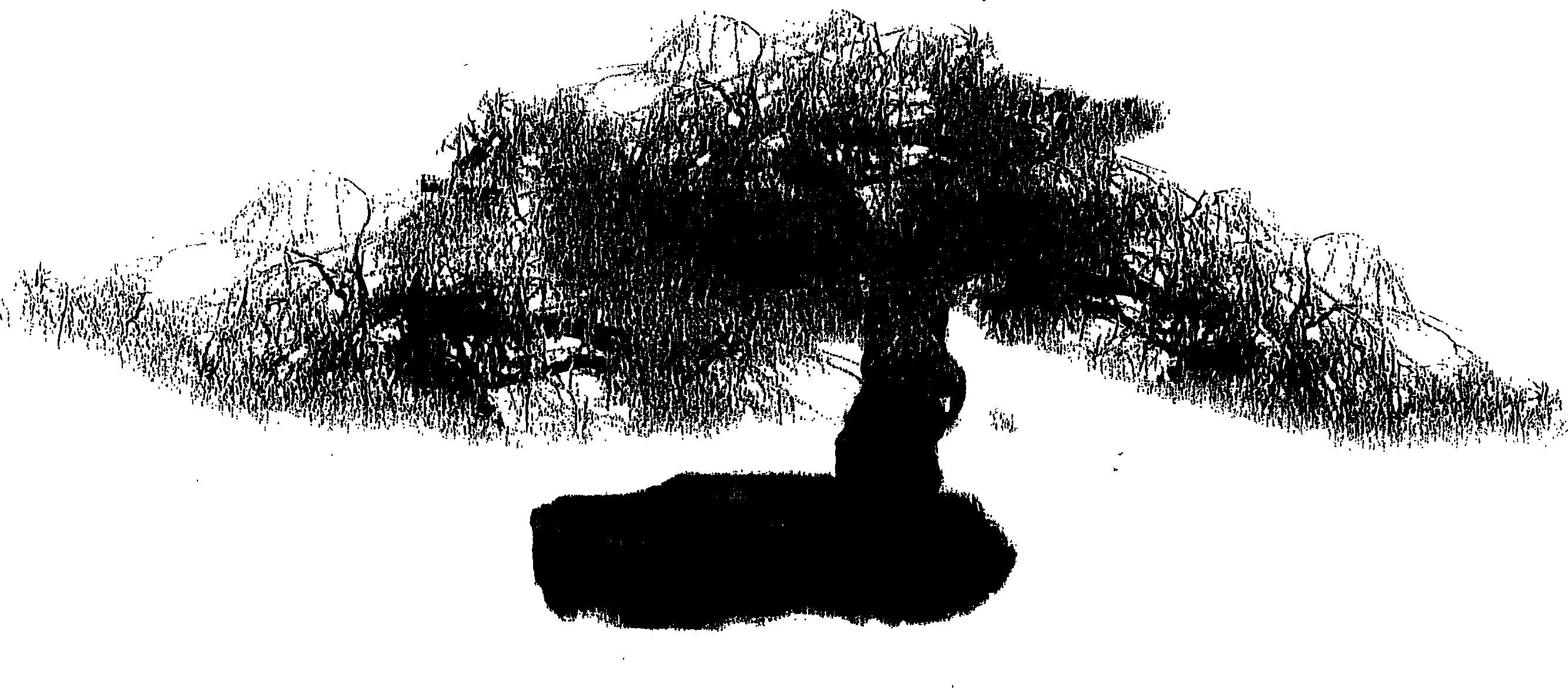

[0020] Embodiment 1 (taking new landscape tree---peach tree as example, see figure 1 )

[0021] 1. Build the infrastructure

[0022] First of all, consider the construction quality of its shaped body, specifically reflecting its firmness, so the internal structure of the shape is very important, so the first step in the construction according to the design plan is the basic structure, based on the principles of building mechanics, using high-quality steel to build make. This embodiment is made with a seamless steel pipe with a diameter of 1.5 inches and an angle steel of 7 cm, and uses the most powerful support to load the weight of the shape;

[0023] 2. Build the exterior structure

[0024] After the basic structure of the main body is completed, the outline of the main body can be made using the steel foundation of the main body. According to the design plan, according to different site needs to play and create. To make the outline, it is necessary to use round steel w...

Embodiment 2

[0035] The difference from Example 1 is:

[0036] 1) In the construction of the basic structure, seamless steel pipes with a diameter of 4 inches and angle steels with a diameter of 3 cm are used to make them;

[0037] 2) In the construction of the exterior structure, the round steel with a diameter of 6mm is mainly used to construct the exterior outline;

[0038] 3) In the initial shape, the galvanized welded wire mesh with a gap of 4mm and a diameter of 0.8mm is bound firmly; then hemp cement ash is applied to the bound wire mesh to make the bottom surface of the shape and form a structural surface to form a stable initial shape;

[0039] 4) molding: add iron oxide pigment with sand ash to adjust into colored sand ash (the ratio of iron oxide pigment in this embodiment in sand ash is 5%, the ash in the described sand ash adopts white cement, the mixture of white cement and sand The ratio is 1:0.8.

Embodiment 3

[0041] The difference from Example 1 is:

[0042] 1) In the construction of the basic structure, seamless steel pipes with a diameter of 3 inches and angle steels with a diameter of 5 cm are used to make them;

[0043] 2) In the construction of the exterior structure, round steel with a diameter of 9mm is used as the main construction of the exterior profile;

[0044] 3) In the initial shape, the galvanized welded wire mesh with a gap of 4.5mm and a diameter of 0.9mm is bound firmly; then hemp cement ash is applied to the bound wire mesh to make the bottom surface of the shape and form a structural surface to stabilize the initial shape ;

[0045] 4) molding: add iron oxide pigment with sand ash to adjust into colored sand ash (the ratio of iron oxide pigment in the present embodiment in sand ash is 4%, the ash in described sand ash adopts white cement, the mixture of white cement and sand The ratio is 1:1.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com