Supercritical fluid expansion-decompression method for preparing superfine powder

A technology of supercritical fluid and ultrafine powder, which is applied in the field of materials to achieve the effect of high product quality and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

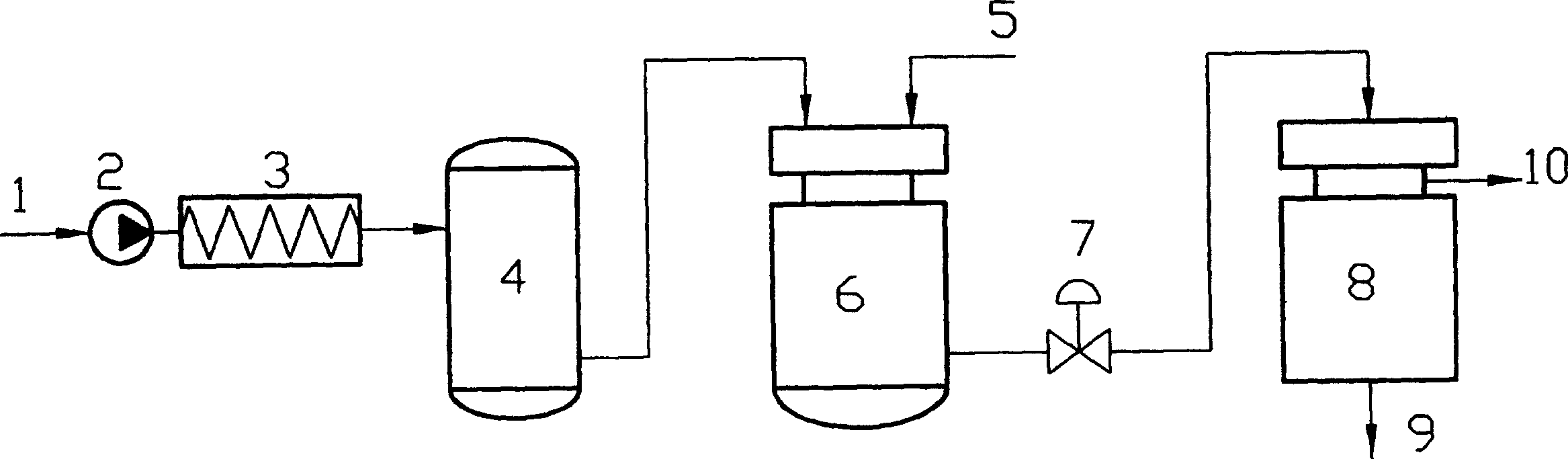

[0013] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0014] The organic solvent enters the dissolution tank 4 after being pressurized and heated by the organic inlet 1 through the solvent pump 2 and the solvent heater 3 successively. Here, the organic solvent with a certain pressure and temperature dissolves the solute (the raw material to be made into ultrafine powder) filled in the dissolution tank to form a solution with a certain concentration, and then enters the mixing tank 6 . At the same time, supercritical CO 2 via CO 2 Inlet 5 enters mixing tank 6 . Here, the solution was mixed with supercritical CO 2 After mixing, a homogeneous multi-element eutectic mixture is formed, and the mixture enters the precipitation tank 8 through a decompression device 7 (such as a decompression valve). In the precipitation tank 8, the multi-component eutectic mixture rapidly decompresses and expands th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com