Nano silver and preparation method and application of nano silver

A nano-silver, reaction technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of inability to accurately control the reaction temperature, limit the wide application of nano-silver, uneven particle size of nano-silver, etc. Problems, to achieve good application prospects, shorten the reaction time, the effect of uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The invention provides a preparation method of nano silver, comprising the following steps:

[0038] The silver nitrate solution and the sodium citrate solution are mixed, and the reduction reaction is carried out in a microwave synthesizer to obtain nano silver;

[0039] The temperature of the reduction reaction is 60-120°C.

[0040] In the present invention, unless otherwise specified, the required preparation raw materials are all commercially available products well known to those skilled in the art.

[0041] The present invention mixes silver nitrate solution and sodium citrate solution. In the present invention, the mass concentration of the silver nitrate solution is preferably 0.0001-0.001 mol / L, more preferably 0.0005-0.001 mol / L. In the present invention, the silver nitrate solution is preferably an aqueous silver nitrate solution, and the process of preparing the silver nitrate aqueous solution is not particularly limited in the present invention, and the s...

Embodiment 1

[0051] Dissolve 0.0849g of silver nitrate in 500mL of deionized water to obtain a silver nitrate solution with a concentration of 0.001M;

[0052] Dissolve 1 g of sodium citrate in 100 mL of deionized water to obtain a sodium citrate solution with a mass concentration of 1%;

[0053] 10 mL of the sodium citrate solution was added with 0.01 M HNO 3 The solution was adjusted to pH 6;

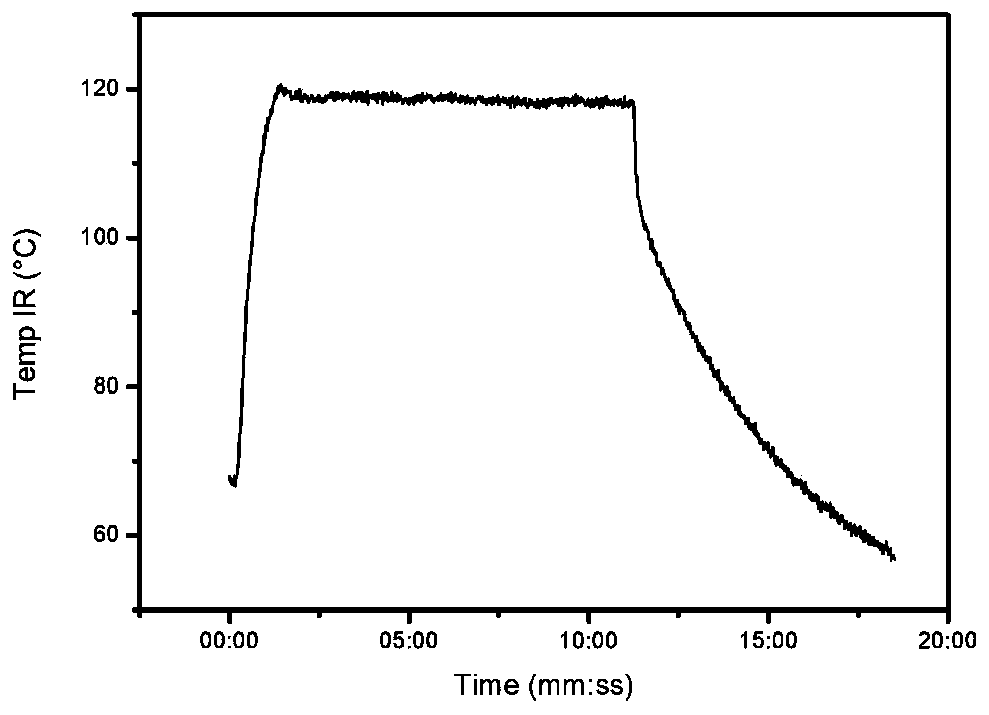

[0054] 50 mL of the above-mentioned silver nitrate solution was heated to boiling, and 5 mL of sodium citrate solution with pH value of 6 was added dropwise, and stirred evenly while adding dropwise. After the dropwise addition, the heat source was removed and cooled; A reduction reaction was carried out (120° C., 10 min); after the reaction, the obtained material was centrifuged, and the supernatant was taken to obtain a nano-silver solution.

[0055] Performance Testing

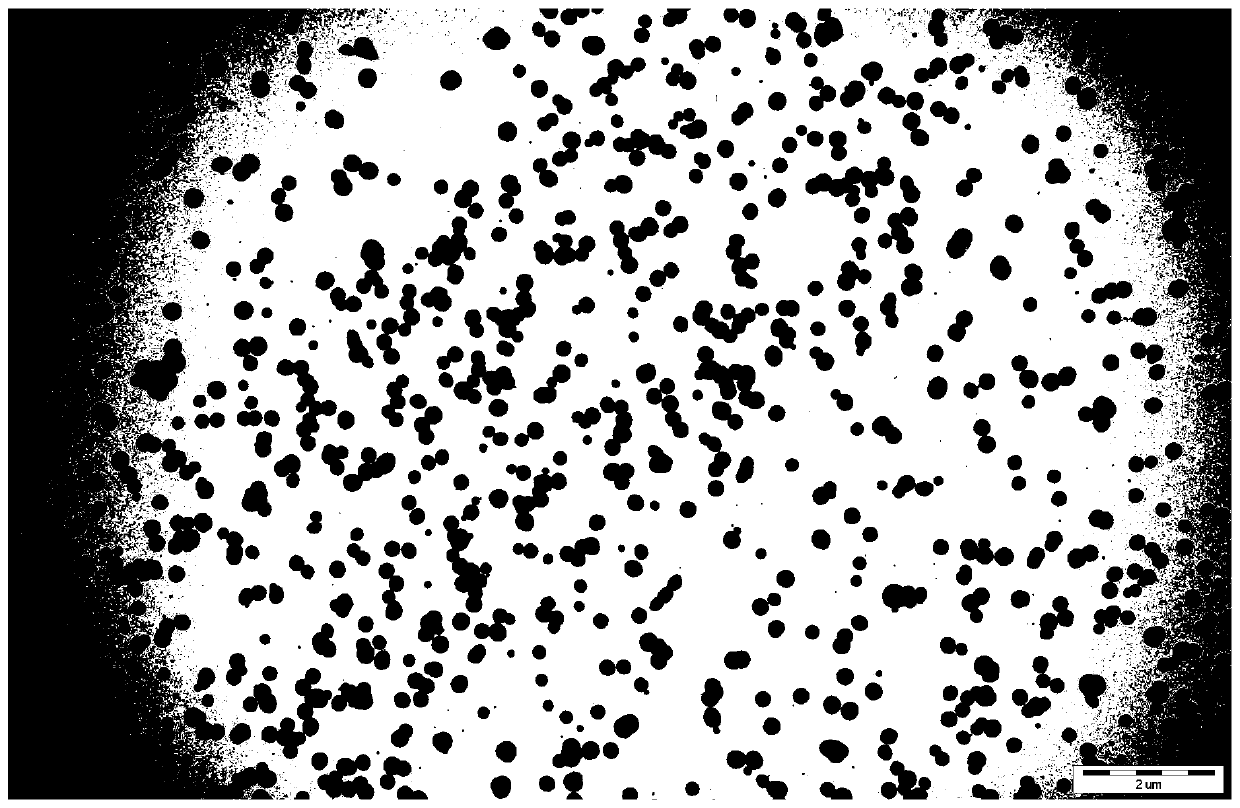

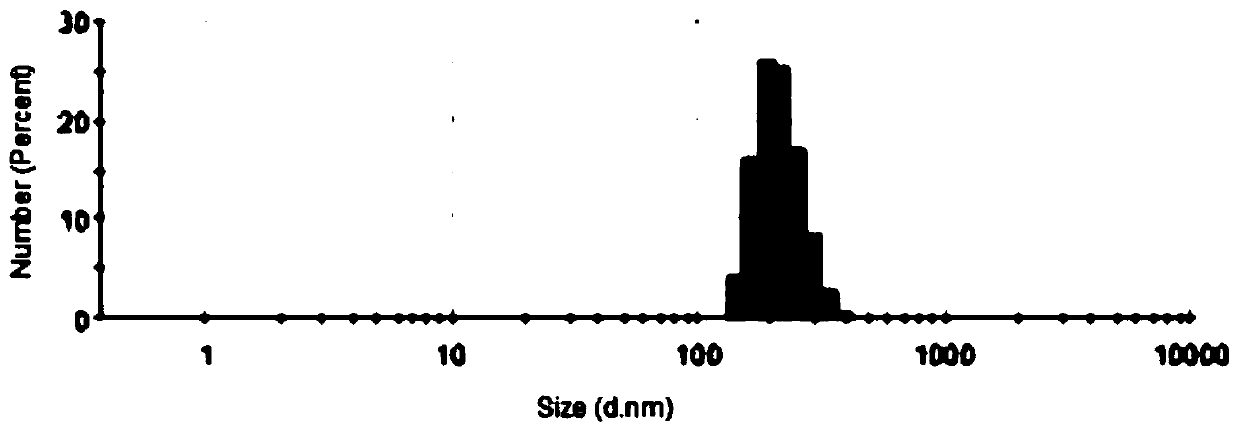

[0056] 1) Carry out SEM characterization and particle size distribution test to the nano-silver prepared in Example 1, the...

Embodiment 2

[0059] Dissolve 0.0849g of silver nitrate in 500mL of deionized water to obtain a silver nitrate solution with a concentration of 0.001M;

[0060] Dissolve 1 g of sodium citrate in 100 mL of deionized water to obtain a sodium citrate solution with a mass concentration of 1%, take 10 mL of sodium citrate solution, and use pH test paper to measure the pH value of 7;

[0061] 50 mL of the above-mentioned silver nitrate solution was heated to boiling, and 5 mL of sodium citrate solution with a pH value of 7 was added dropwise, and stirred evenly while adding dropwise. After the dropwise addition, the heat source was removed and cooled; A reduction reaction was carried out (120° C., 10 min); after the reaction, the obtained material was centrifuged, and the supernatant was taken to obtain a nano-silver solution.

[0062] Performance Testing

[0063] 3) SEM characterization and particle size distribution test are carried out to the nano-silver prepared in Example 2, and the results...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com