Pneumatic pulverization device and low temperature pulverization method using the same

A jet crushing and low-temperature crushing technology, which is applied in grain processing and other fields, can solve problems such as difficult fine crushing, achieve constant crushing particle size, and suppress thermal denaturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Embodiments of the present invention will be described below.

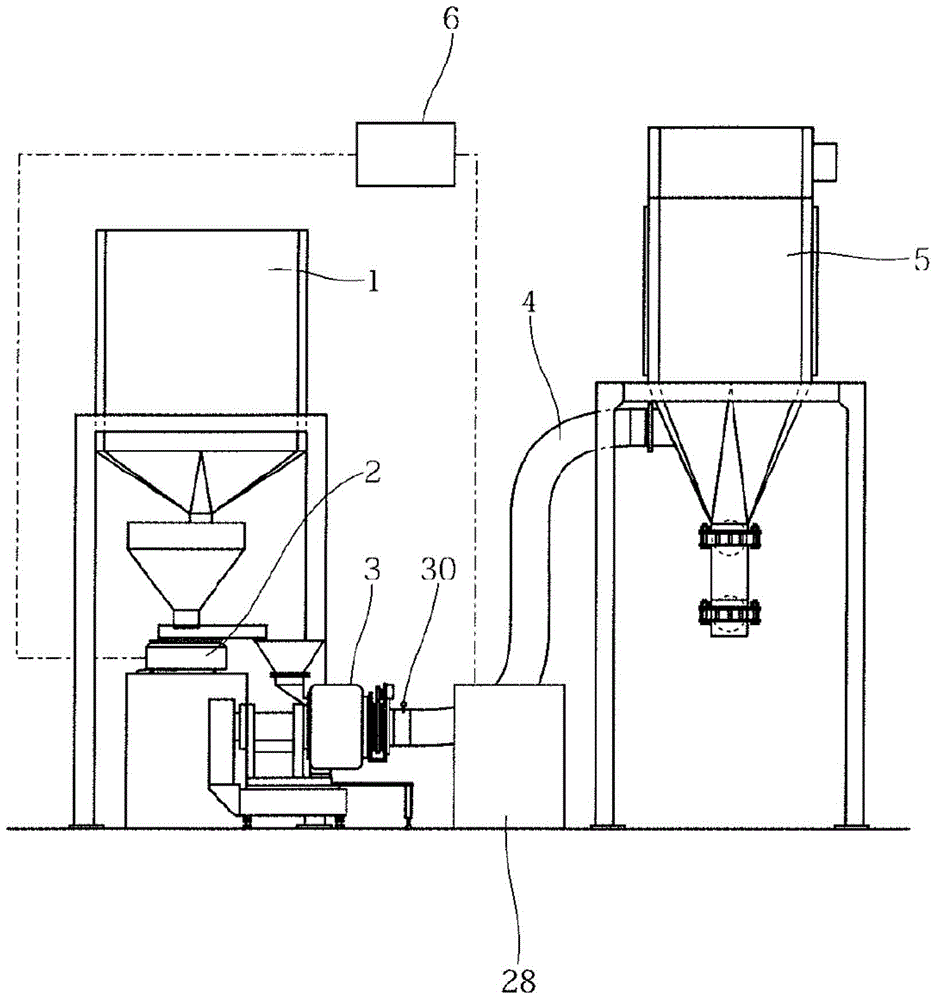

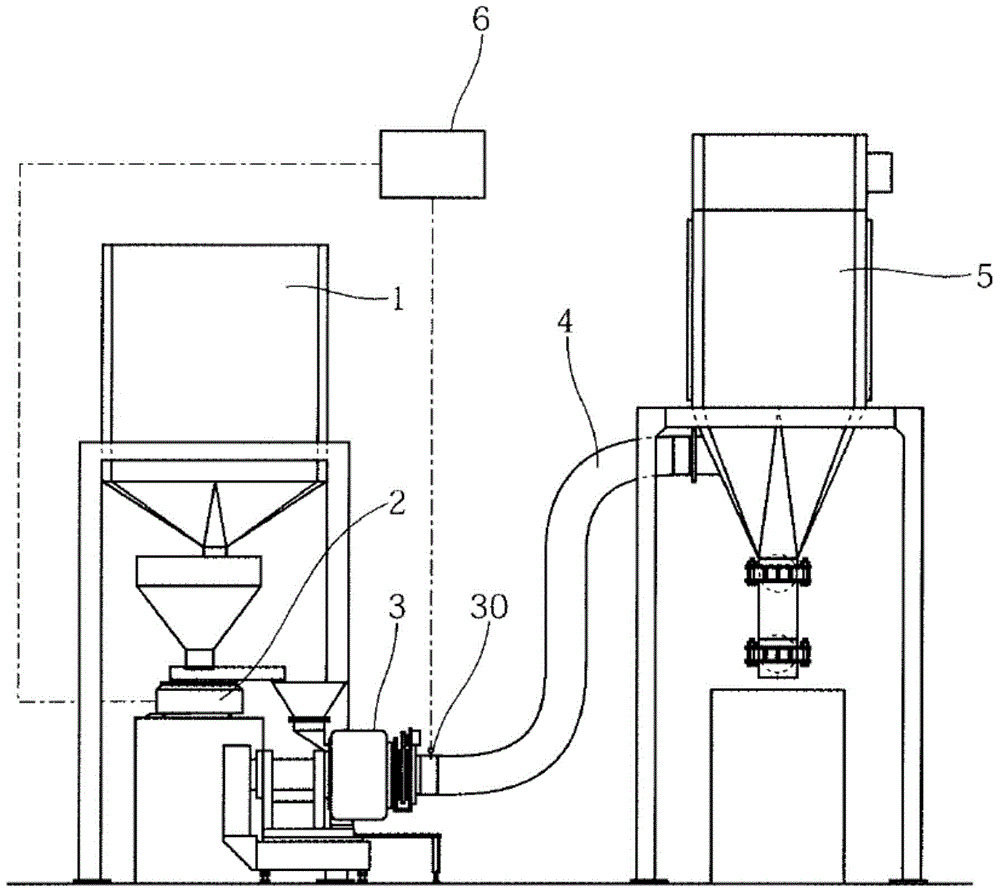

[0057] figure 1 1 is an explanatory diagram of the first embodiment of the present invention, 1 is a raw material hopper, 2 is a raw material supply machine, 3 is a jet mill, 4 is a suction duct, and 5 is a pulverized material recovery hopper. In addition, although the raw material used in each embodiment is soybean, it may be other grains, such as adzuki bean and rice.

[0058] Soybeans as a raw material are fed from a raw material hopper 1 to a raw material feeder 2 installed therebelow, and are then supplied to a jet mill 3 . The raw material feeder 2 is a vibrating quantitative supply device, and its raw material supply amount is controlled by the control device 6 as will be described later.

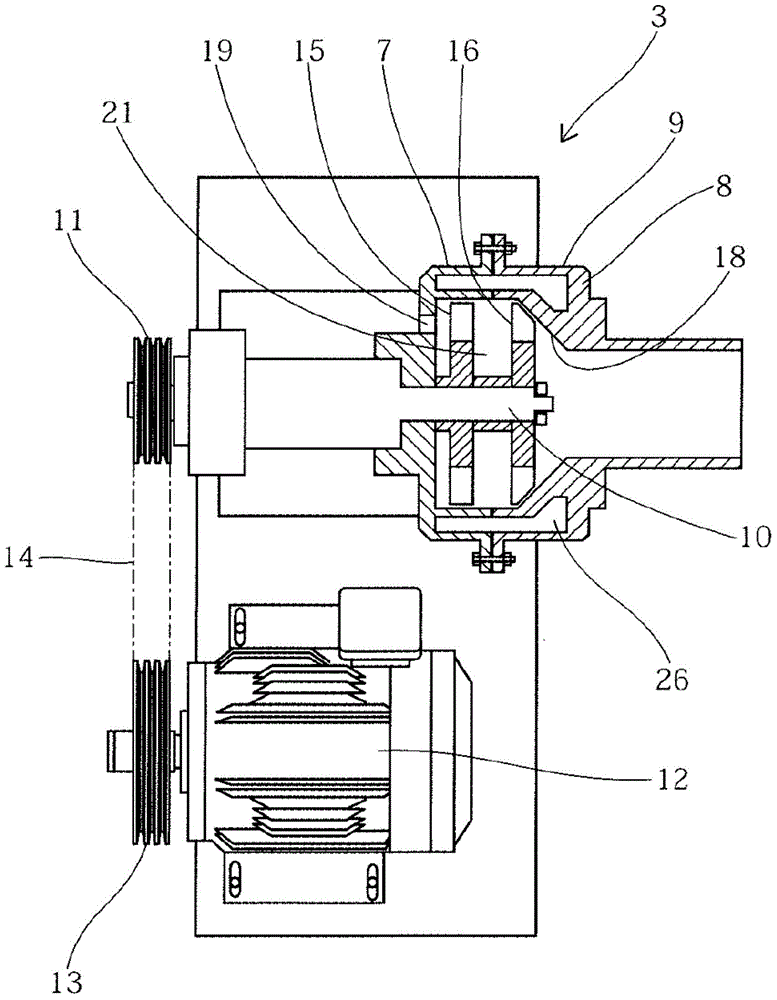

[0059] figure 2 Details of the jet mill 3 are given. The jet mill 3 has a casing 9 including a cylindrical main body 7 and a conical front cover 8 . A rotating shaft 10 with a cantilever structure is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com