Steel material for thermal cutting using oxygen

A technology for thermal cutting and steel, applied in the field of steel for thermal cutting, which can solve the problems of not guaranteeing laser cutting properties, and not having itself, and achieve the effect of good laser cutting properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

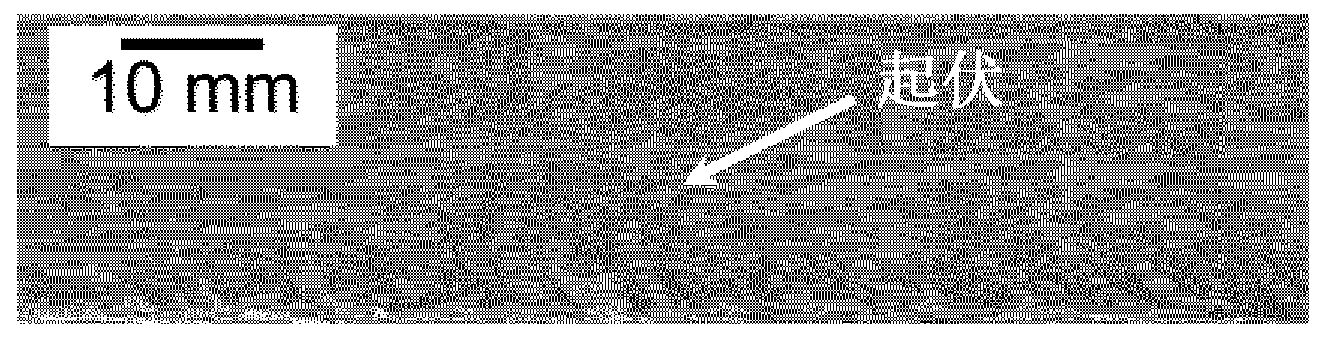

[0120] The slabs of steel No.1 to No.22 having the chemical composition shown in Table 1 were heated to 1120°C, and after the initial scale was removed by descaling, they were rolled at a finishing temperature of 750°C to 900°C to Three types of steel materials were obtained with plate thicknesses of 16mm, 25mm, and 32mm. After that, wait for the scale to grow, and correct the flatness with a leveler after water cooling. Scale remains on the surface of manufactured steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com