Flux composition and solder paste composition for soldering containing acrylic resin

A composition and flux technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of easy cracking, circuit metal corrosion, circuit short circuit, etc., to inhibit cracks and inhibit separation. , the effect of inhibiting thermal denaturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

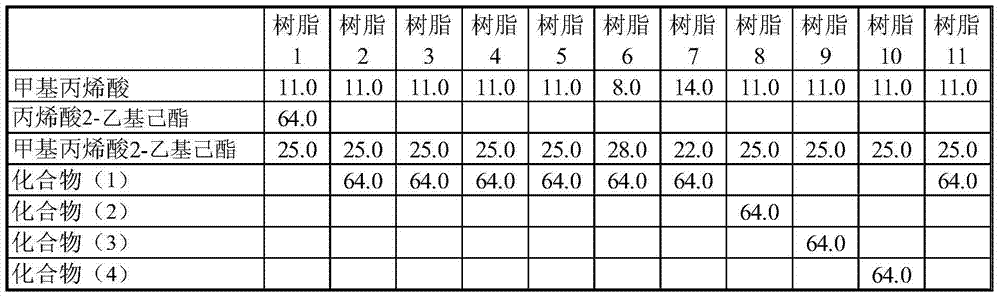

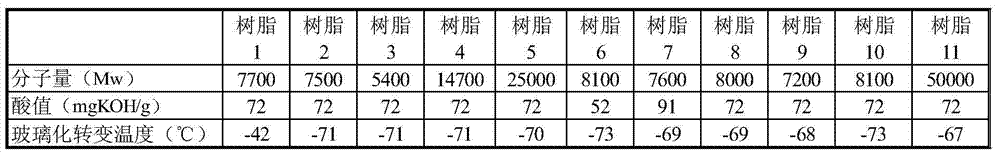

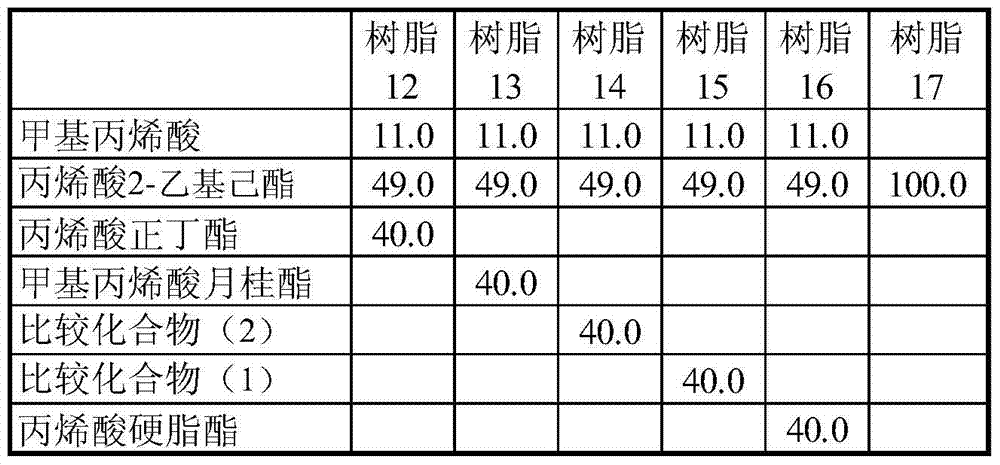

[0079] The present invention will be described in detail below with reference to Examples and Comparative Examples. In addition, this invention is not limited to these Examples.

[0080] Synthesis of a compound containing a saturated alkyl group having a straight chain structure with 2 to 20 carbons

Synthetic example 1

[0082] 243.4g (3.38mol) of acrylic acid and 630.3g (2.6mol) of 2-hexyldecanol (CAS registration number: 2425-77-6) were added to a 2,000ml 4-neck flask equipped with a stirrer and a reflux condenser. OXOCOL1600, manufactured by Nissan Chemical Industry Co., Ltd.), 74.1 g (0.39 mol) of p-toluenesulfonic acid monohydrate, 4 g of p-methoxyhydroquinone, and 900 g of toluene were reacted under reflux for 6 hours. The solution was neutralized with a saturated aqueous sodium bicarbonate solution, extracted with ethyl acetate, and then concentrated to obtain 756 g of a compound (1) represented by the following general formula (7) (yield: 98%).

[0083] [chemical formula 7]

[0084] ···Formula (7)

Synthetic example 2

[0086] 756 g of a compound represented by the following general formula (8) was obtained under the same conditions as in Synthesis Example 1 except that 2-stearyl alcohol (trade name: FINE OXOCOL 180T, manufactured by Nissan Chemical Industries, Ltd.) was used as the raw material alcohol (2) (Yield: 98%).

[0087] [chemical formula 8]

[0088] ···General formula (8)

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com