A kind of environment-friendly high-temperature direct injection disperse black dye ink and preparation method thereof

A technology of dye ink and disperse black, which is applied in dyeing, ink, textiles and papermaking, etc. It can solve the problems of prohibited aromatic amine exceeding the standard, insufficient saturation and high conductivity, and achieve less salting out, high saturation and high conductivity low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1: A kind of environment-friendly high-temperature direct-injection disperse black dye ink and its preparation method and application

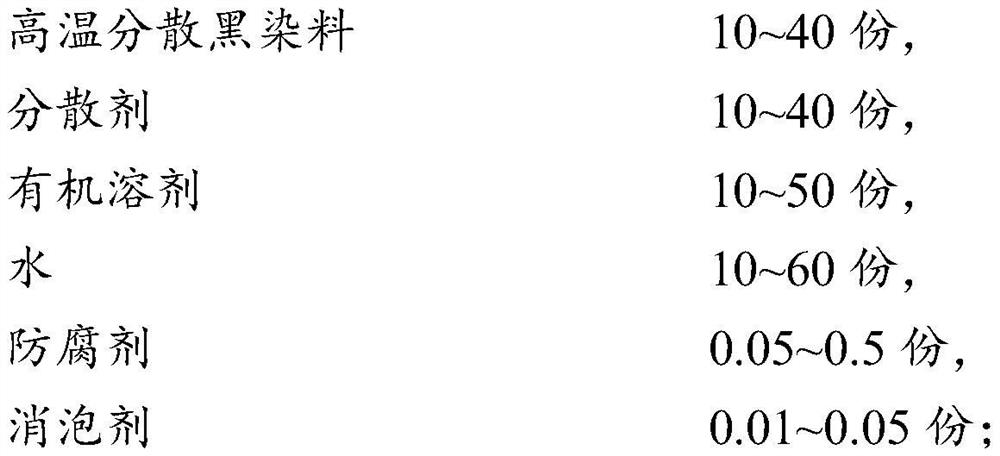

[0058] Environmentally friendly high-temperature direct-injection disperse black dye ink consists of the following raw materials in parts by mass:

[0059]

[0060] Among them, high-temperature disperse black dye is compounded from high-temperature disperse blue, high-temperature disperse orange and high-temperature disperse red. In the compounded high-temperature disperse black dye, high-temperature disperse red 177 accounts for 20% by mass percentage, and high-temperature disperse red 177 accounts for 20%. Disperse orange 44 accounted for 40%, high-temperature disperse blue 79 accounted for 40%, and zetasperse 3700 was selected as the dispersant.

[0061] Preparation of environment-friendly high-temperature direct-injection disperse black ink:

[0062] Step 1, according to the number of parts by mass, at room temperatur...

Embodiment 2

[0068] Embodiment 2: A kind of environment-friendly high temperature direct injection disperse black dye ink and its preparation method and application

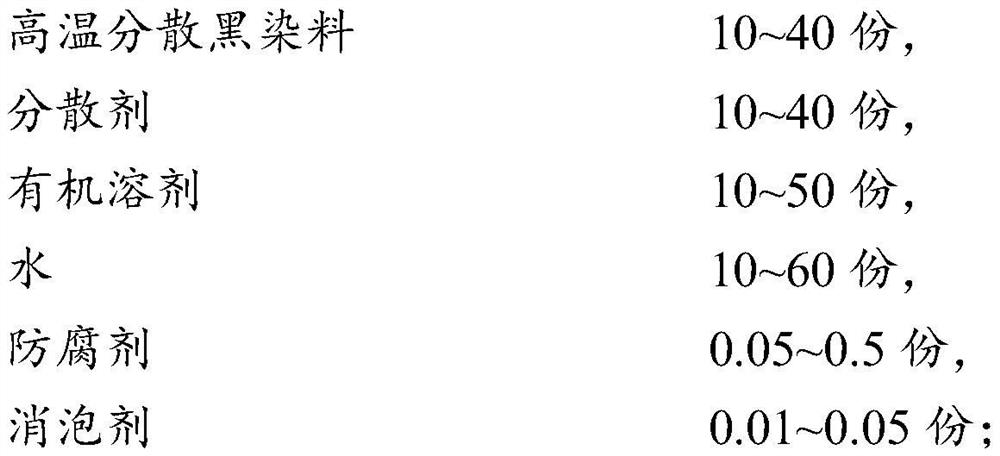

[0069] Environmentally friendly high-temperature direct-injection disperse black dye ink consists of the following raw materials in parts by mass:

[0070]

[0071]

[0072] Among them, the high-temperature disperse black dye is compounded from high-temperature disperse blue, high-temperature disperse orange and high-temperature disperse red. In the compounded high-temperature disperse black dye, high-temperature disperse red 311 accounts for 15% by mass percentage, and high-temperature disperse red 311 accounts for 15%. Disperse orange 44 accounted for 40%, high-temperature disperse blue 79:1 accounted for 45%, and the dispersant was Zetasperse 3400.

[0073] The preparation and application of the environment-friendly high-temperature direct-injection disperse black ink are the same as those in Example 1.

Embodiment 3

[0074] Example 3: A kind of environment-friendly high temperature direct injection disperse black dye ink and its preparation method and application

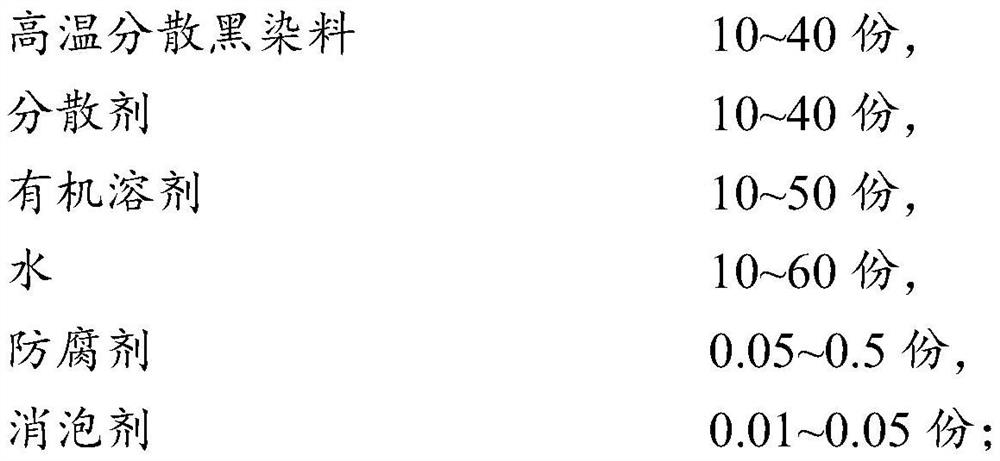

[0075] Environmentally friendly high-temperature direct-injection disperse black dye ink consists of the following raw materials in parts by mass:

[0076]

[0077] Among them, the high-temperature disperse black dye is compounded from high-temperature disperse blue, high-temperature disperse orange and high-temperature disperse red. In the compounded high-temperature disperse black dye, in terms of mass percentage, high-temperature disperse red 311 accounts for 12%, and high-temperature disperse red 311 accounts for 12%. Disperse orange 44 accounts for 40%, high temperature disperse blue 79:1 accounts for 48%.

[0078] In terms of mass percentage in the compound dispersant, Zetasperse 3100 accounts for 30%, Zetasperse 3600 accounts for 20%, Zetasperse 3800 accounts for 30%, and non-ionic diffusing agent accounts for 20%. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com