Automatic storage system

An automatic storage and storage area technology, applied in the direction of control/adjustment system, storage device, control components, etc., can solve the problems that cannot meet the transportation volume of the stacker, the production line cannot work, and the transportation path is complicated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

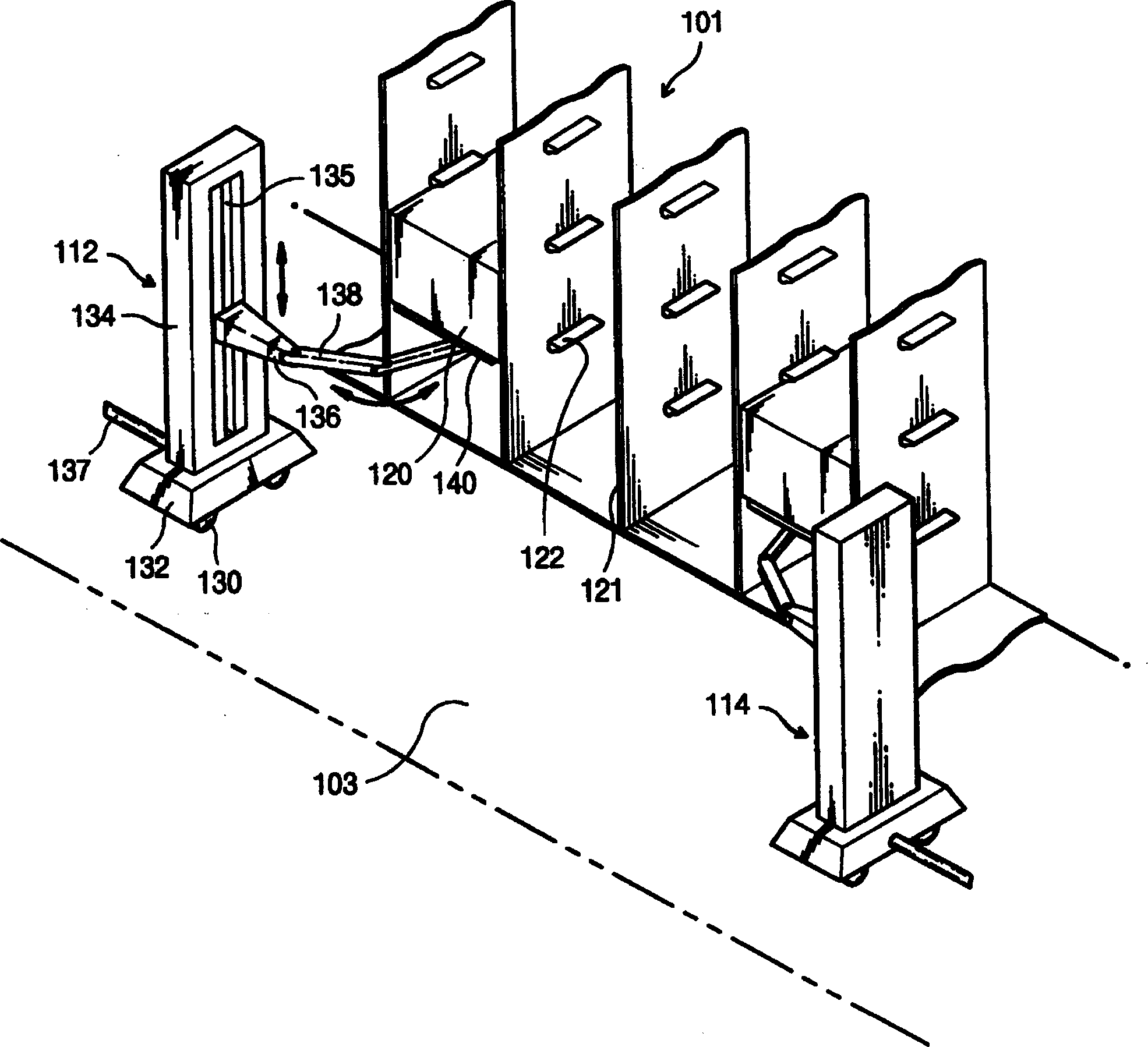

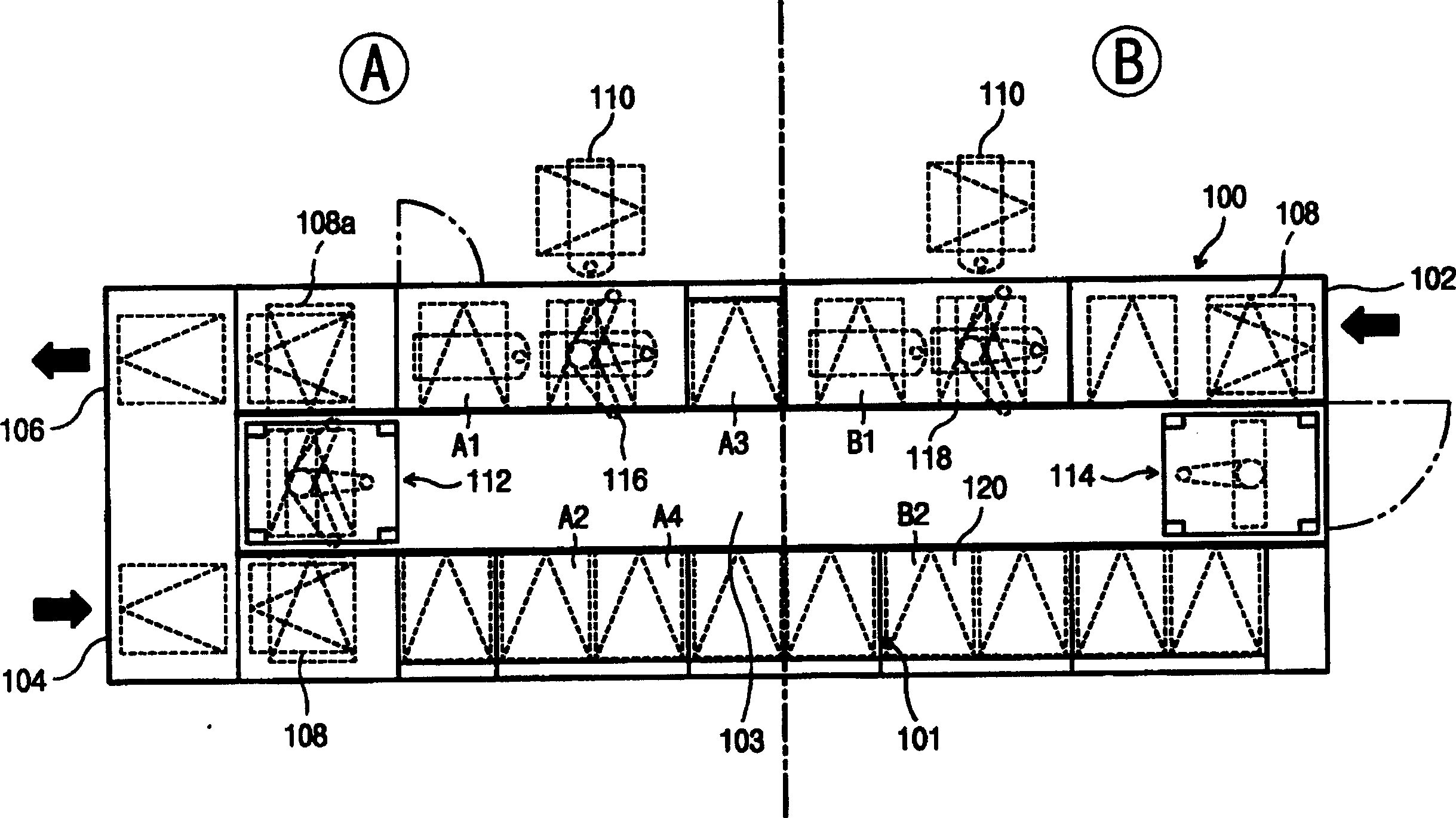

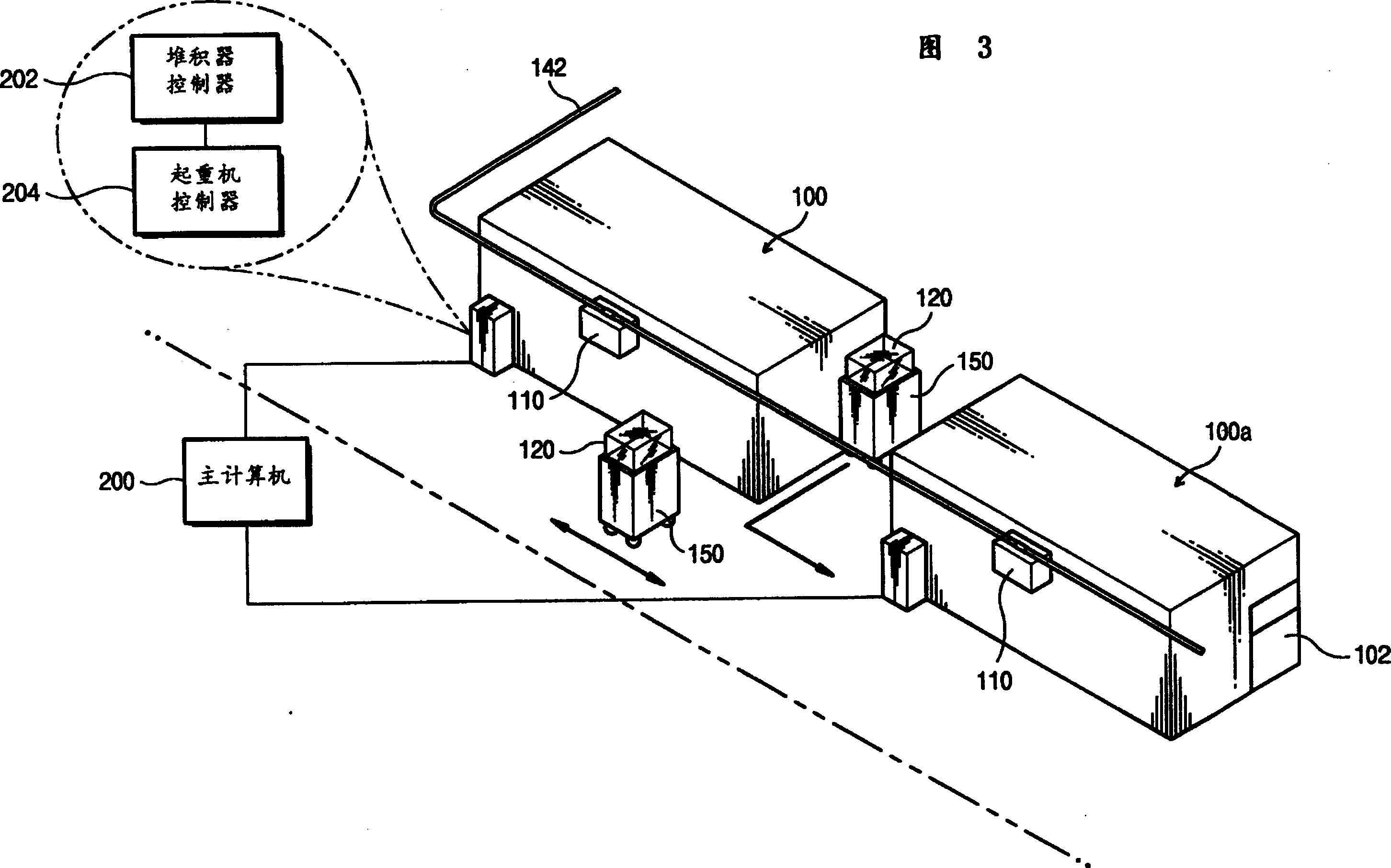

[0018] The invention provides a new and improved automatic storage system, which includes a storage area with constant space, a loading device for loading workpieces in the storage area, and a controller. This automatic storage system is of the stacker type with a storage area and a loading device.

[0019] In the place of the stacker 100 shown in FIG. 3, the system is integrated with the processing equipment of the production line, or separate from the processing equipment in order to load workpieces subjected to constant processing steps. Automated guided vehicles (AGVs) 150 are used to transport workpieces 120 in the bay. AGV150 transports workpieces in and between warehouse partitions. Compared with the rail-guided vehicle (RGV) that moves along the track, the AGV does not need a track and can move directly to the floor of the production line. As shown in FIG. 3 , the AGV receiving the workpiece 120 from the stacker 100 performs an operation of transporting the workpiece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com