Method for cold process deposition of antiglare layer

An anti-reflection and build-up layer technology, applied in coatings, layered products, sputtering, etc., can solve the problems of increased absorption of MgF2 layer, cumbersome methods, and increased production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] In order to characterize the properties of the antireflective buildups obtained according to the method of the invention, we prepared antireflective buildups on organic substrates (CR39) using different high refractive index materials.

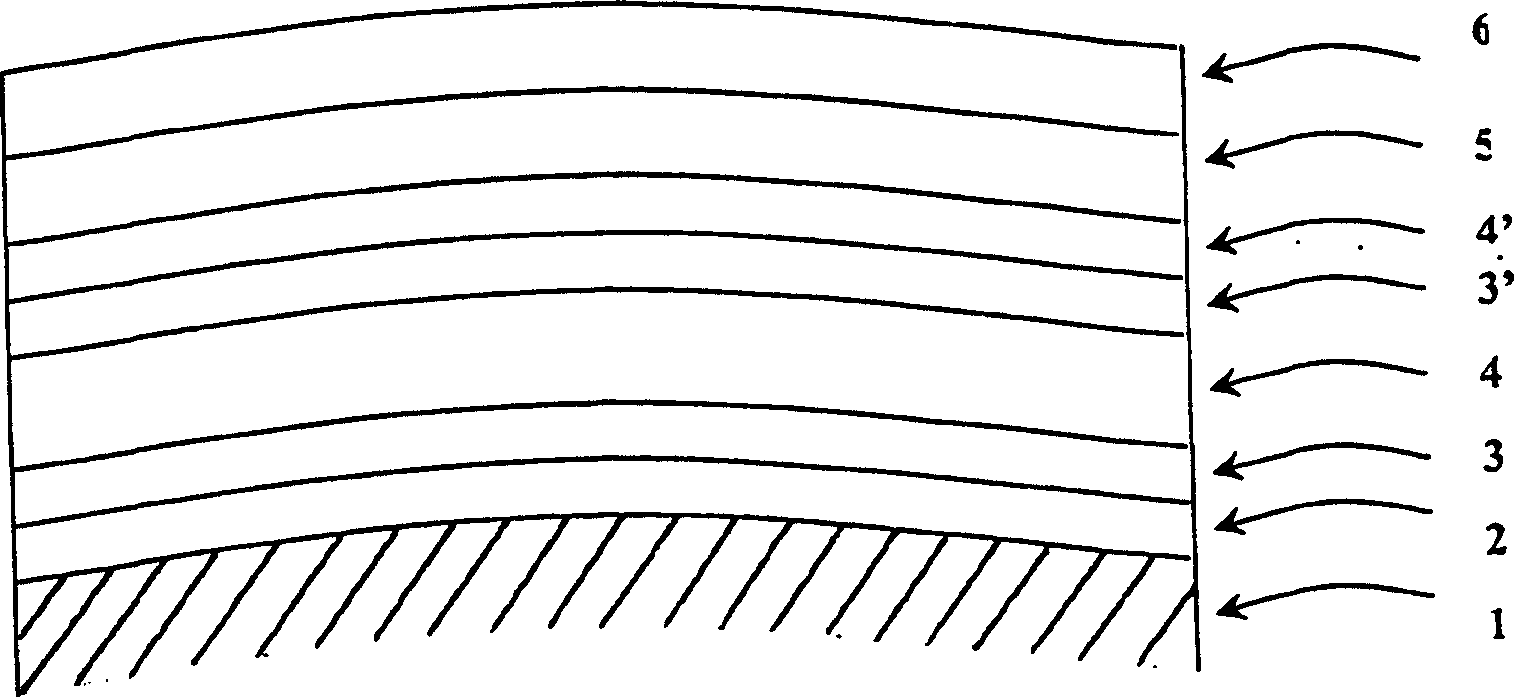

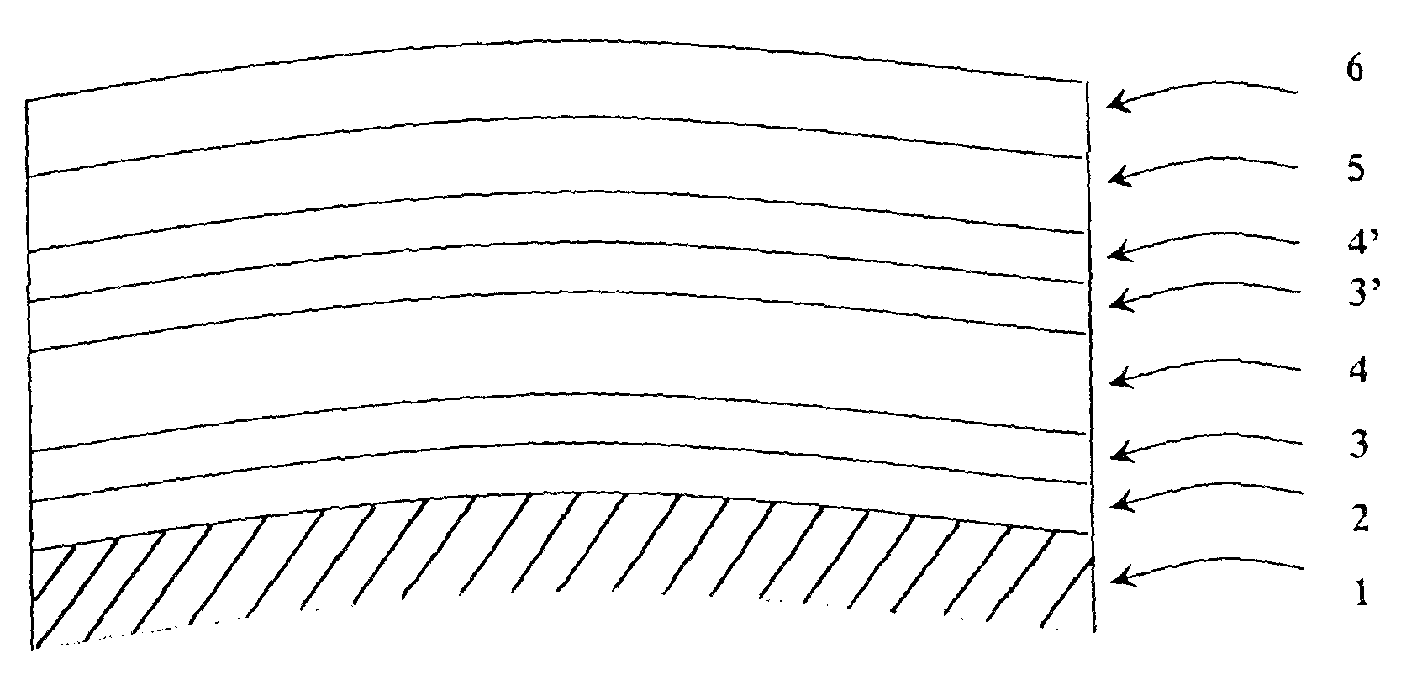

[0047] SiO for matrix 2 / HI / SiO 2 / HI / MgF 2 Coating layer coating consisting of four layers of overcoating type (HI stands for material with high refractive index).

[0048] The process of the invention is carried out with a Balzers BAK 760 vacuum evaporator.

[0049] The different HI materials used are listed in the table below. The respective suppliers are indicated in parentheses. For each high refractive index material, we treated the bottom layer of HI material with ion bombardment in the presence of argon gas at a voltage of 100 V and a current of 1 A for 1 min to obtain a matrix, The second matrix was not treated with ion bombardment. Next, MgF was deposited by vacuum evaporation without ion assistance 2 .

[0050] In the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com