Method for synthesizing blue copper ore mineral pigment

A technology of mineral pigments and azurite, applied in copper compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the basic principles of cultural relics restoration, the difficulty of long-term preservation of paintings, and the complicated steps of azurite pigments, etc. problems, to achieve the effect of improving resource utilization efficiency, solving increasing scarcity, and solving complicated process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] see figure 1 , figure 1 It is a schematic flow chart of the method for synthesizing azurite pigments in some embodiments of the present invention. The synthetic method described in the embodiment of the present invention includes: S11: preparing a reaction solution; in this step, preparing a reaction solution containing Cu 2+ brine solution, then add CO containing 3 2- and HCO 3 - At least one of the salts (that is, at least one of carbonate and bicarbonate), so as to form the first mixed solution.

[0040] According to an embodiment of the invention, the preparation of Cu 2+ The concentration of the saline solution is not particularly limited, and can be selected according to actual needs. For example, according to a specific embodiment of the present invention, Cu 2+ The concentration of the saline solution may be 0.1-1 mol / L, preferably 0.2-0.4 mol / L. According to an embodiment of the invention, the preparation of Cu 2+ The volume of the saline solution is ...

Embodiment 1

[0069] Prepare a beaker with a capacity of 500 ml, dissolve 15 g of copper nitrate trihydrate in 200 ml of deionized water, the solution is dark blue; then add 6 g of calcium carbonate powder, and stir. Keep the beaker below 14 degrees Celsius, and stir vigorously for 1 minute every 20 minutes. After about 2 hours, there will be bubbles in the solution, and after 8 hours, a blue precipitate will be formed, and the oscillation will be stopped; keep the temperature and let it stand for 24 hours hours, and stirred twice more within 24 hours. After 24 hours, ultrasonic dispersion was used to obtain a suspension, the suspension was subjected to sedimentation treatment, the precipitate was collected, washed, and dried in a vacuum oven at 70 degrees Celsius to obtain about 5.4 grams of azurite product with a yield of 78%. .

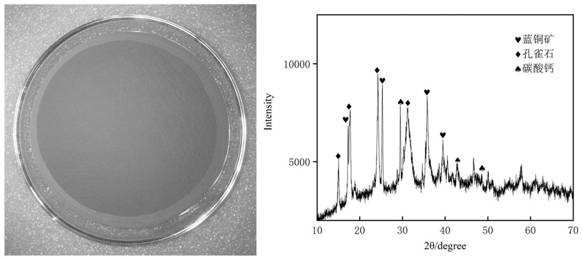

[0070] Product testing: the obtained product and the XRD phase test results of the product are as follows: figure 2 As shown, the XRD results show that most ...

Embodiment 2

[0072] Prepare a glass bottle with a sealing ring of 500 ml in capacity, dissolve 15 grams of copper nitrate trihydrate in a glass bottle filled with 200 ml of deionized water, the solution is dark blue; then add 6 grams of calcium carbonate powder, and seal the glass bottle. Keep the sealed glass bottle below 12 degrees Celsius, and vibrate vigorously for 1 minute every 20 minutes. After 2 hours, bubbles will appear in the solution, and after 6 hours, a blue precipitate will form. Stop shaking; keep the temperature and let it stand for a while. Leave for 24 hours, then shake twice within 24 hours. After 24 hours, ultrasonic dispersion was used to obtain a suspension, the suspension was subjected to sedimentation, the precipitate was collected, washed, and dried in a vacuum oven at 70 degrees Celsius to obtain about 6 grams of azurite product with a yield of 87%. .

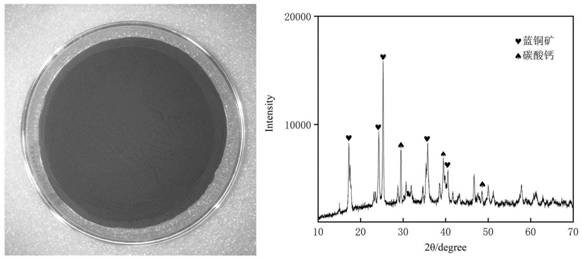

[0073] Product testing: the obtained product and the XRD phase test results of the product are as follows: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com