Method for guiding plate link chainsin area of reversing devices of pedestrian conveyor system

A transmission system and slewing device technology, which is applied in escalators, transportation and packaging, etc., can solve the problems of difficult control of polygonal and slewing effects, and achieve the effects of reducing polygonal effects, enhancing quiet operation, and excellent operating characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

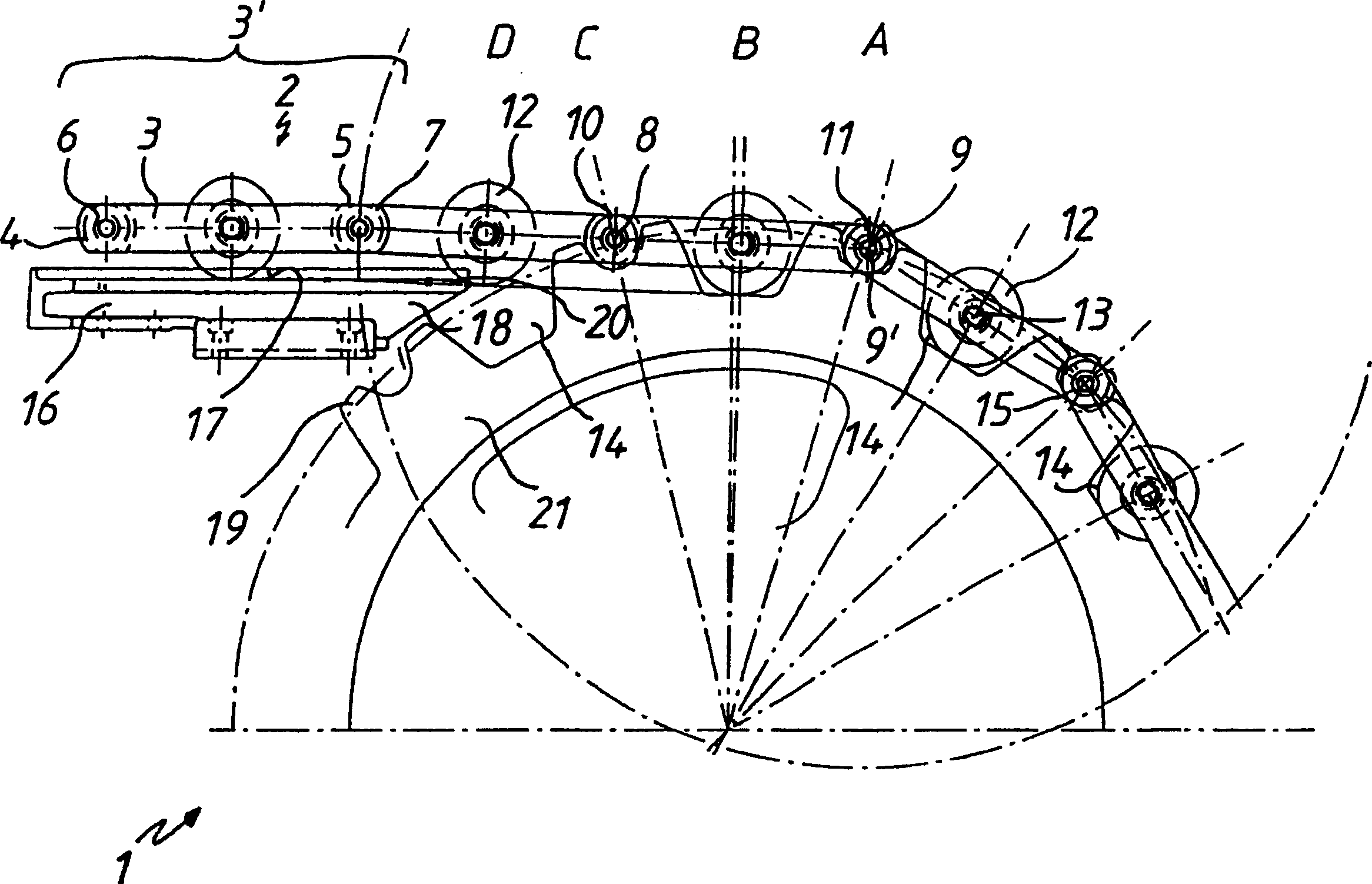

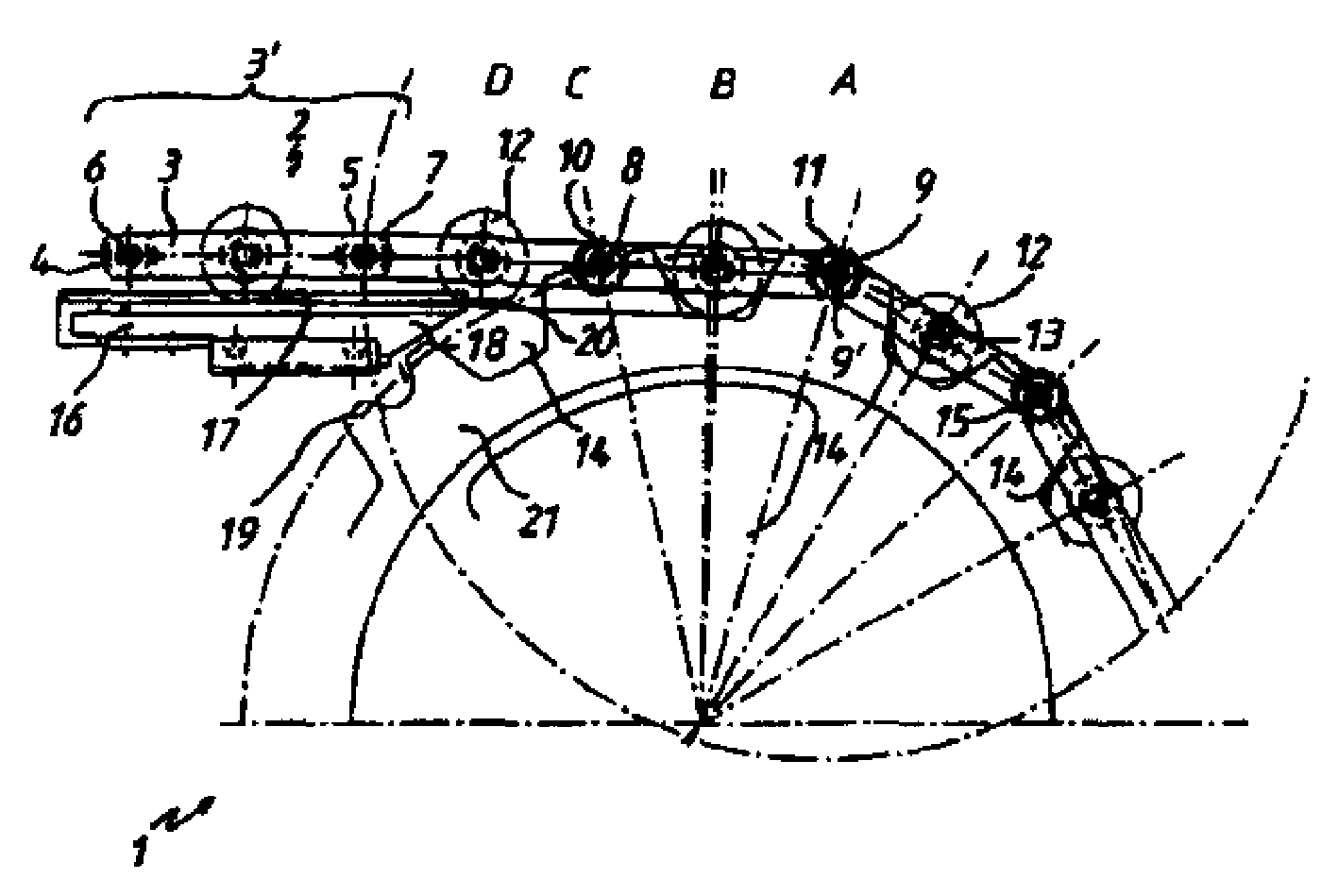

[0023] The schematic diagram illustrates the swivel area 1 of the slat chain 2 . Therein, the flight link chain 2 comprises individual flight links 3 guided in parallel in an interacting relationship with one another in their connection areas via connection elements 6, 7, forming flight flight elements 3'. The connecting elements 6 , 7 are formed by pins 8 , 9 and guide bushes 10 , 11 . Between the connecting regions 4 , 5 of the individual parallel chain plates 3 , at approximately half-height, guide rollers 12 are arranged, rotatable about axes 13 . If possible, without generating polygonal and turning effects, the link chain 2 turns around a sprocket 21 arranged therein, for example, in the turning region 1 of an escalator or a moving walk (not shown further). The sprocket 21 is provided with a circular seat 14 for receiving the guide roller 12 . Between the circular seats 14 , an engagement zone 15 is provided for receiving and guiding the connection elements 6 , 7 ie bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com