Probe type composite pressure sensor

A pressure sensor, probe-type technology, applied in the field of sensors, can solve the problems of inability to adapt to the coefficient of dynamic friction, compact working space structure, undiscovered, complex structure, etc., and achieves the effect of small size, wide application range and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

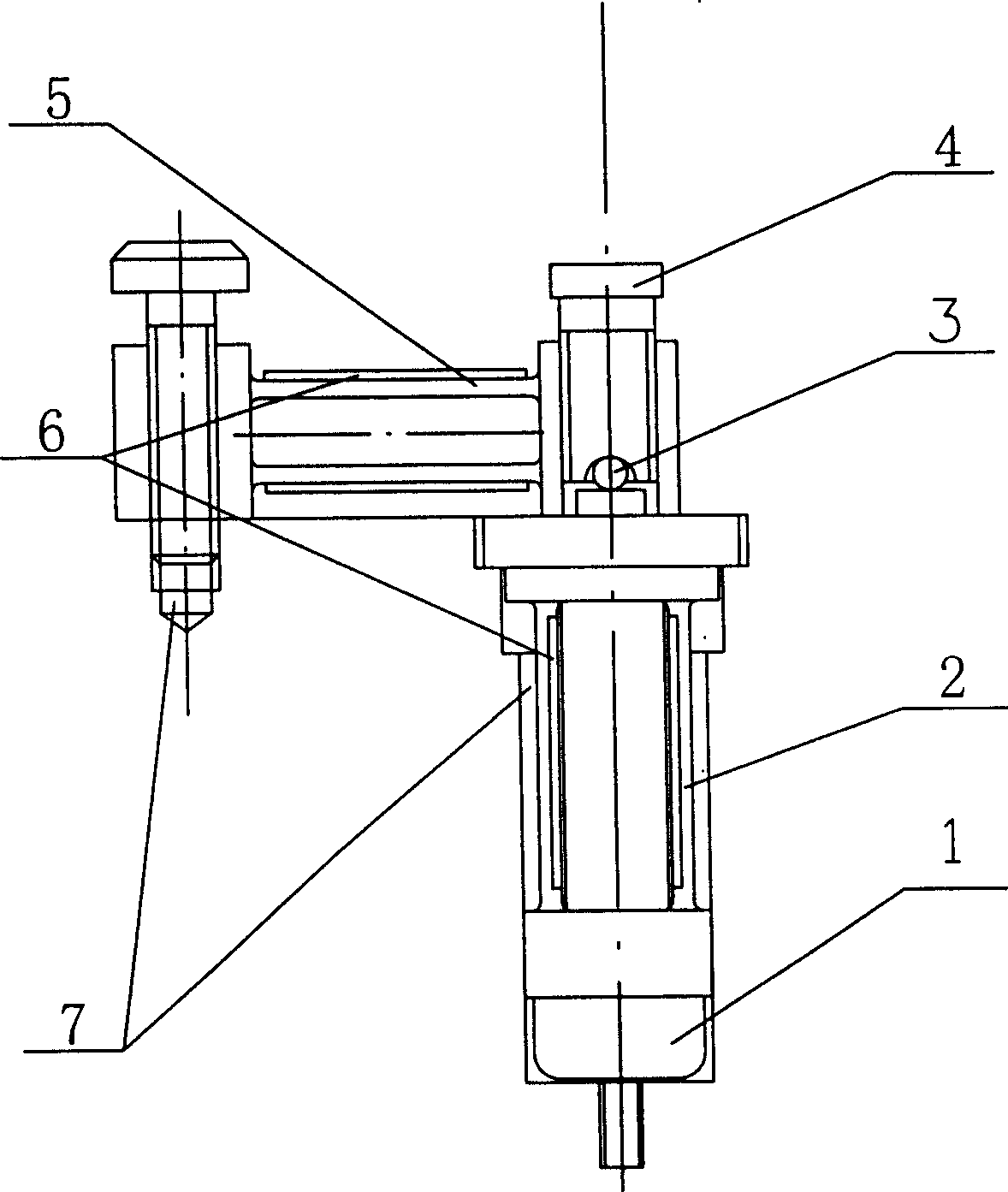

[0011] Such as figure 1 As shown, the present invention includes: probe 1, tangential force cantilever beam elastic body 2, ball 3, pre-tightening bolt 4, positive force cantilever beam elastic body 5, pasted resistance strain gauge 6, and its connection relationship is: The needle 1 passes through the tangential force cantilever beam elastic body 2 and then contacts with the positive force cantilever beam elastic body 5 through three balls, and the ball 3 and the pre-tightening bolt 4 are relatively fixed on the positive force cantilever beam elastic body 5. The cantilever beam elastic body 2 is relatively fixed in the mold workpiece 7 through the probe 1 and the pre-tightening bolt 4, and the positive force cantilever beam elastic body 5 is fixed on the mold workpiece 7 by screws. Paste-type resistance strain gauges 6 are pasted on the elastic body 2 of the force cantilever beam.

[0012] The small probe 1 is used to transmit the deformation. The head size of the probe 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com