Actuator for operation of gearless driving machine of elevator

A transmission gear and drive equipment technology, applied in the field of wheel drive equipment, can solve the problems of unsafe, expensive, and complicated operations, and achieve the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

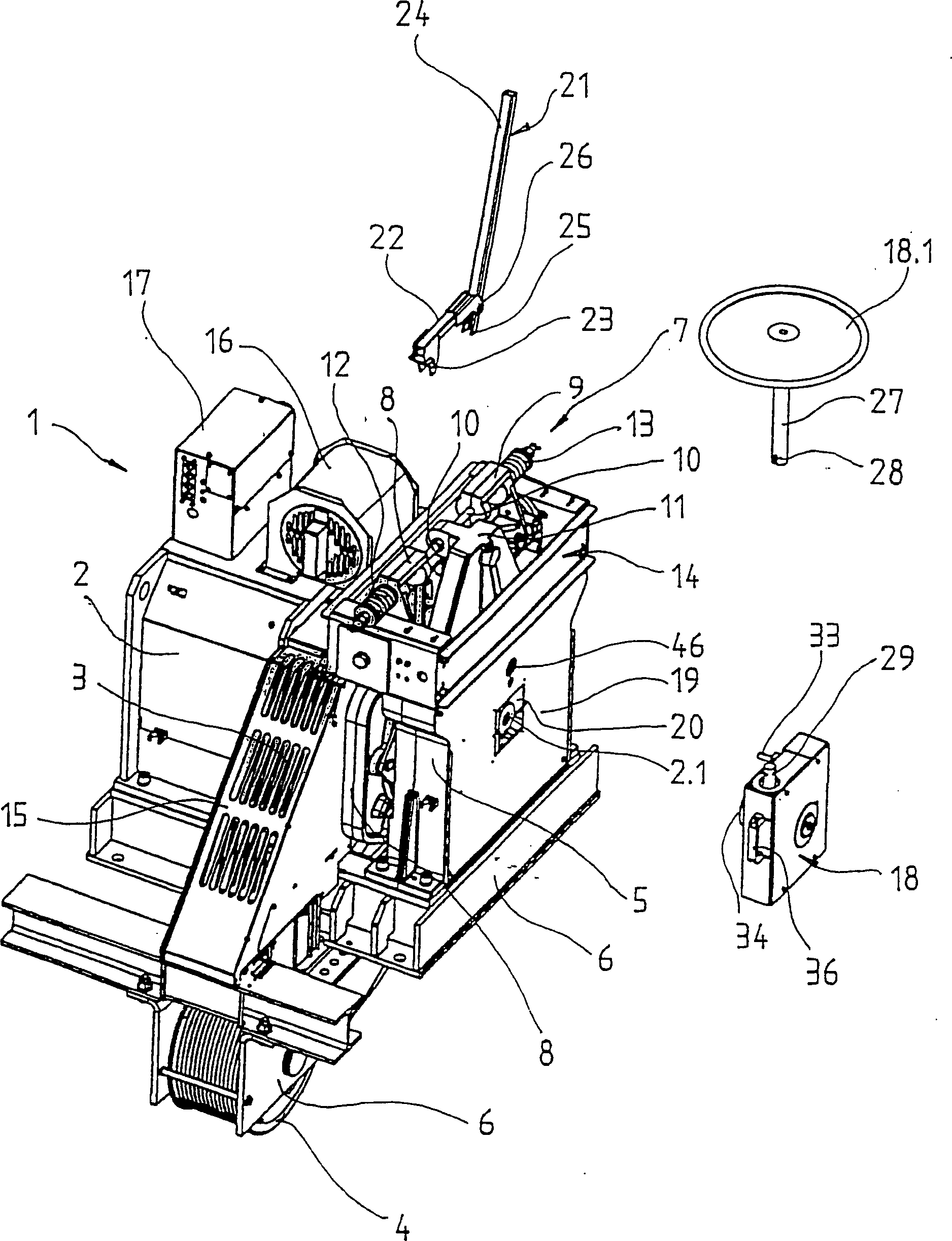

[0014] figure 1 A gearless drive unit 1 is shown with an electric motor 2 consisting of a stator and a rotor for driving a drive wheel 3 . Cables not shown in the figure go around the driving wheel 3 and the reversing roller 4, said cables suspend an elevator car not shown in the figure and a counterweight not shown in the figure and drive the latter two. The driving wheel 3 is fixed on the motor shaft 2.1, one end of the motor shaft is pivotally connected to the bearing cap and the other end is pivotally connected to the bearing seat 5. Motor 2, bearing cover, bearing seat 5 and reversing roller 4 are fixed on the machine bracket 6.

[0015] The drive unit comprises a brake device 7 with a first brake lever 8 and a second brake lever 9 on which each a brake shoe is arranged. The lower ends of the brake levers 8 , 9 are pivotally connected to the bearing housing 5 and their upper ends are guided by a rod 10 . The middle of the rod 10 is set on a bracket 11 connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com