Triazine-based compound comprising functionalized alkylthio groups, and photo polymerization initiator

A kind of compound, technology of triazine derivatives, applied in the field of photosensitive compositions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

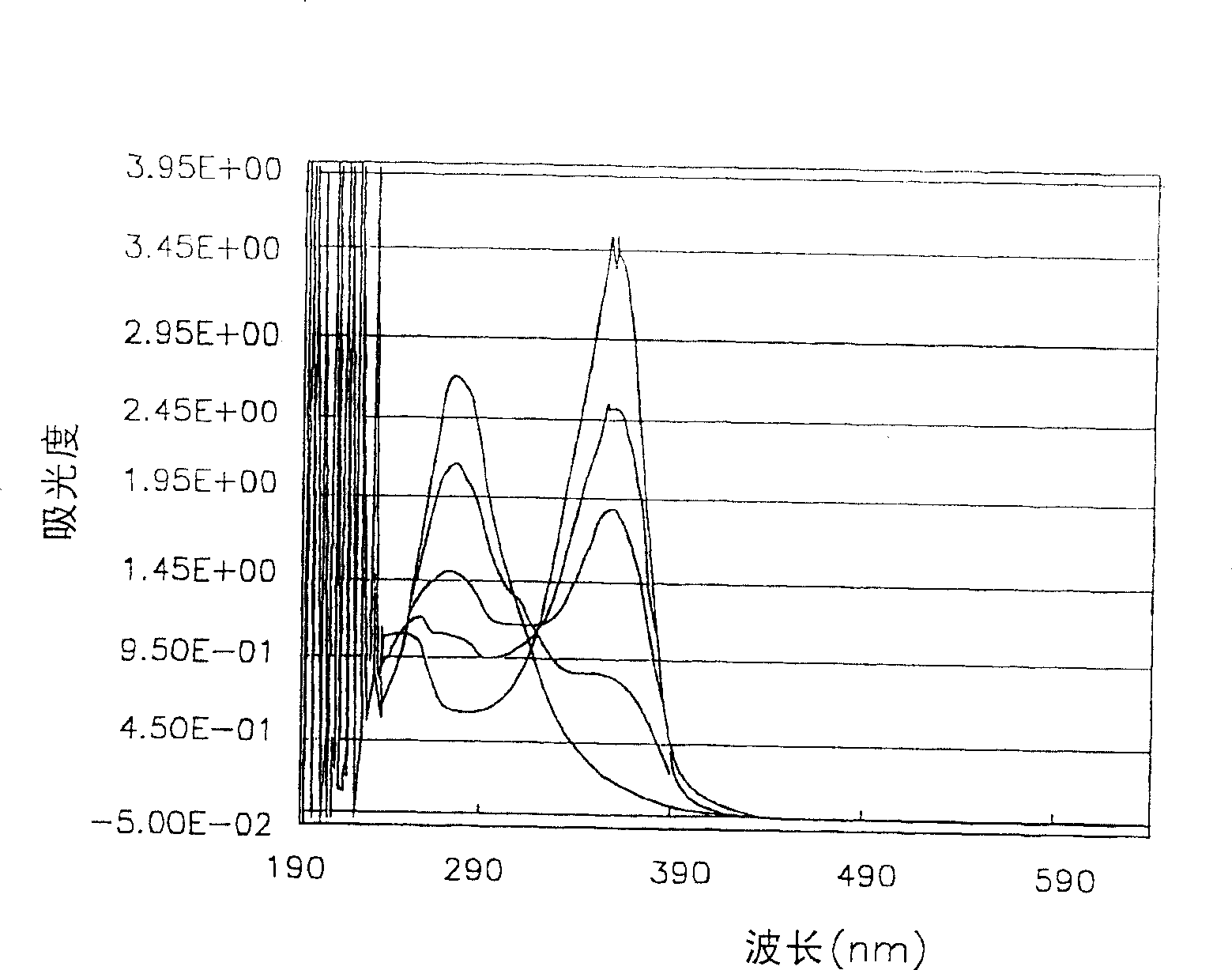

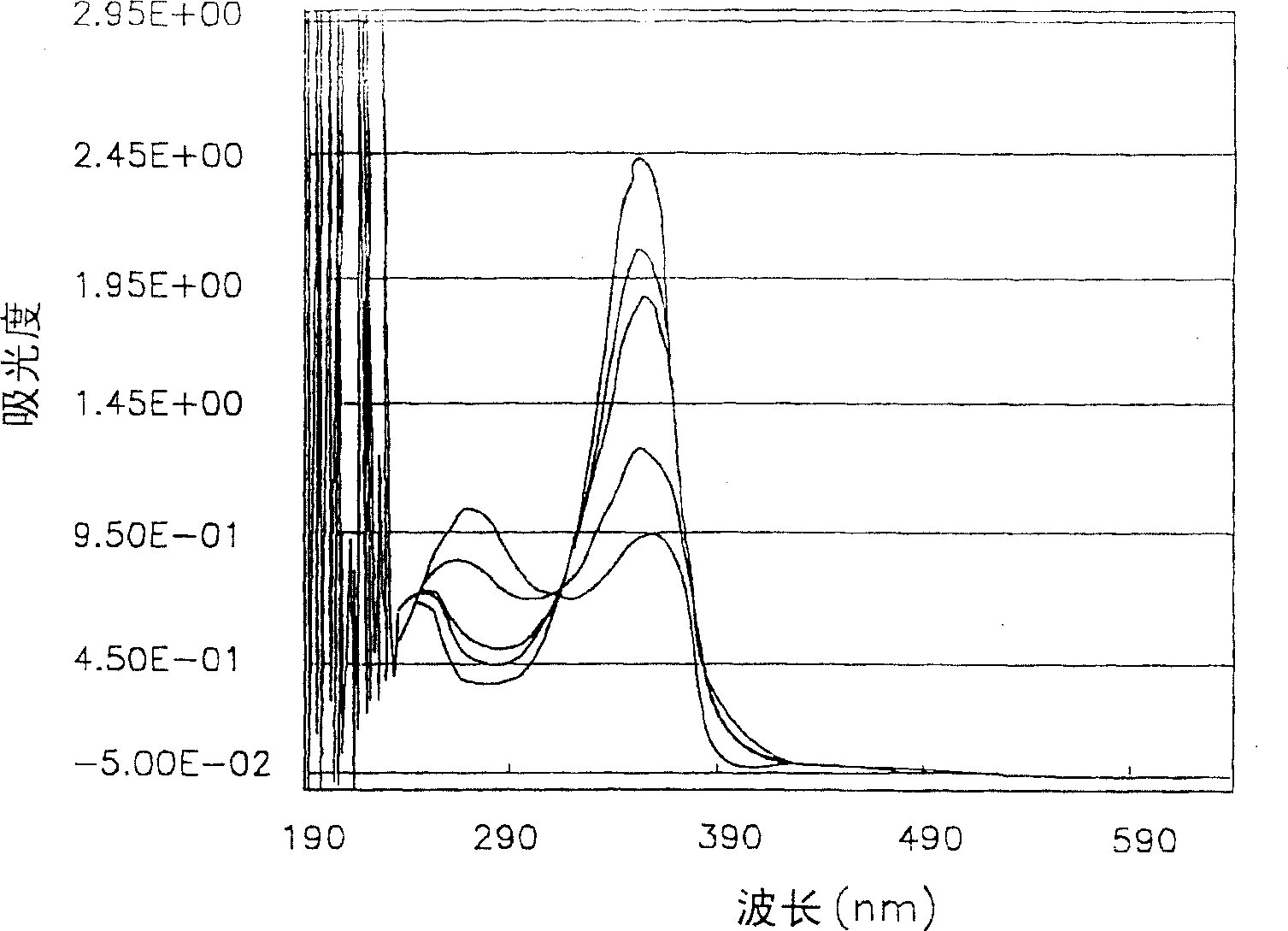

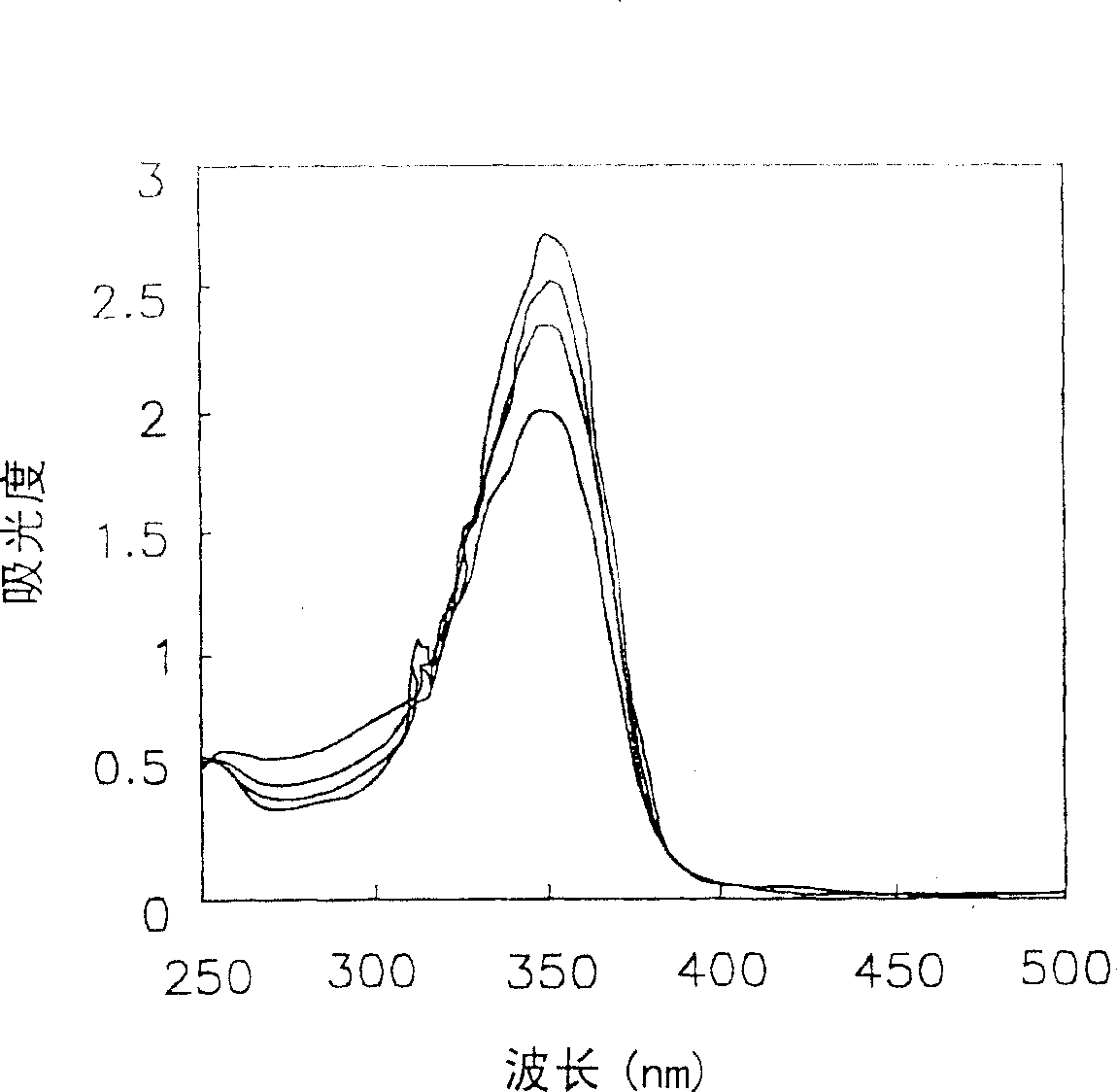

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1: the preparation of 3-{4-[2,4-bis(trichloromethyl)-s-triazin-6-yl]phenylthio}propionic acid shown in the following chemical formula 1a

[0052] [chemical formula 1a]

[0053]

[0054] [Step 1: Synthesis of 3-(4-cyanophenylthio)propionic acid]

[0055] Put 20g of 4-fluorobenzonitrile (165 mmol), 20 g of 3-mercaptopropionic acid (188 mmol) and 50 g of potassium carbonate into 300 ml of DMF (dimethylformamide), and keep the bath temperature at 100°C for 20 Hour.

[0056] After the reaction temperature dropped to room temperature, the reaction solution was slowly poured into 1500 ml of distilled water, and then the generated precipitate was removed by filtration. The filtrate was acidified with 2N hydrochloric acid solution (pH reached 2 as determined with pH paper), at which point an organic precipitate formed. After filtering and washing the precipitate with distilled water, the product was dried in a vacuum oven, and its structure was analyzed by NMR (nu...

Embodiment 2

[0062] Embodiment 2: 1,1,1,3,3,3-hexafluoroisopropyl-3-{4-[2,4-bis(trichloromethyl)-s-three represented by the following chemical formula 1b Preparation of oxazin-6-yl]phenylthio}propionate

[0063] [chemical formula 1b]

[0064]

[0065] [Step 1: Synthesis of 3-(4-cyanophenylthio)propionic acid]

[0066] Put 20g of 4-fluorobenzonitrile (165mmol), 20g of 3-mercaptopropionic acid (188mmol) and 50g of potassium carbonate into 300ml of DMF (dimethylformamide), and keep the bath temperature at 100°C for 20 hours.

[0067] After the reaction temperature dropped to room temperature, the reaction solution was slowly poured into 1500 ml of distilled water, and then the formed precipitate was filtered out. The filtrate was acidified with 2N hydrochloric acid solution (use pH paper to ensure the pH reached 2), at which point an organic precipitate formed. The precipitate was filtered and washed with distilled water, and the product was dried in a vacuum oven, and its structure was...

Embodiment 3

[0078] Embodiment 3: the preparation of 2-{4-[2,4-bis(trichloromethyl)-s-triazin-6-yl]phenylthio}acetic acid ethyl ester shown in the following chemical formula 1c

[0079] [chemical formula 1c]

[0080]

[0081] [Step 1: Synthesis of ethyl 2-(4-cyanophenylthio)acetate]

[0082] Put 15g of 4-fluorobenzonitrile (124mmol), 16g of ethyl 2-mercaptoacetate (133mmol) and 25g of potassium carbonate into 100ml of DMF (dimethylformamide), and keep the bath temperature at 130°C for 20 hours.

[0083] After the reaction temperature dropped to room temperature, the reaction solution was slowly poured into 700ml of distilled water, extracted with ether, washed with distilled water, dried with anhydrous magnesium sulfate, and filtered. Next, the volatile materials were evaporated to give the crude product. The crude product was purified by column chromatography using a mixed solvent of hexane and ethyl acetate (3:1 by volume) as an eluent. The product structure was analyzed by NMR (nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com