Method for direct metal making by microwave energy

A metallic, direct technology for energy efficiency, process efficiency improvements, furnaces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

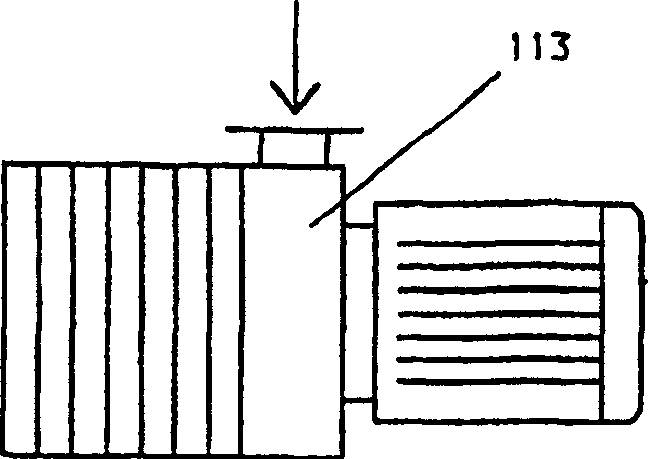

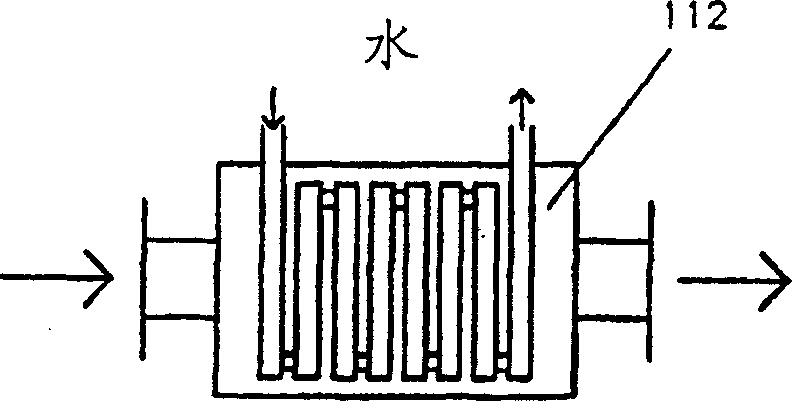

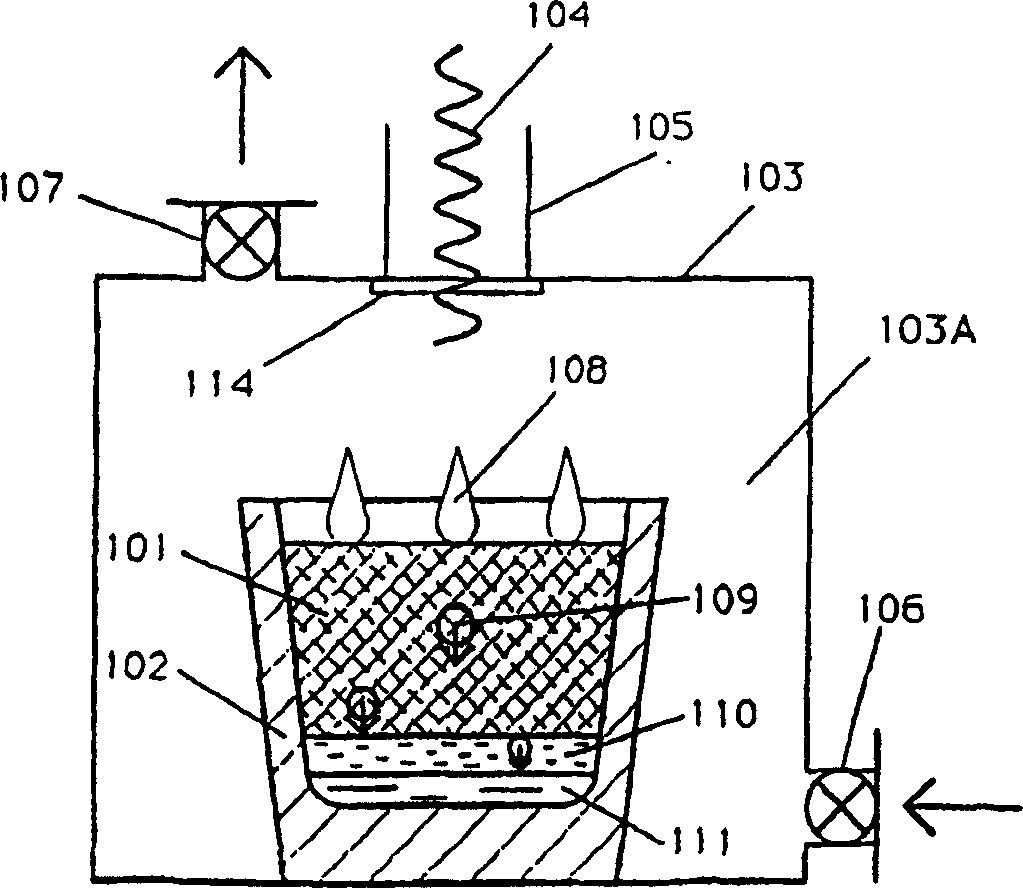

Image

Examples

example 1

[0048] A sample was prepared containing iron ore concentrate containing 65% iron mixed with 15% carbon black as reducing agent, 1% lime as flux and 5% pulverized coal as auxiliary fuel. The mixture was filled into refractory clay crucibles and loaded into a microwave treatment unit MCR200, manufactured by Wavemat Ltd. The device includes a 2.45Ghz microwave generator with a power of 300W - 3000W. This microwave device can be used with adjustable single-mode or controllable multi-mode microwave chambers. The chamber can be evacuated or continuously flushed with inert or reducing gas. A single mode of 1 kw power was used and the sample was heated to 1200 °C within 10 minutes. Measure the temperature on the outer surface of the crucible with a pyrometer. The temperature inside the crucible was not measured, but was known to be higher than 1200°C. During the heating period, the pulverized coal burns and creates a flame. The samples were incubated at about 1200°C for about 2 m...

example 2

[0050] A Cu-containing 2 A sample of S powder mixed with a stoichiometric amount of 7.5% carbon black as reducing agent. The mixture was filled into a refractory clay crucible and loaded into a microwave processing unit MCR200. The microwave chamber is constantly filled with N 2 The discharge port of the flushing forced incision chamber is connected to a scrubber. The scrubber consisted of a glass flask with a side tube and a rubber stopper for sealing its mouth. Fill half a flask with 10% basic NaOH solution. A tube through a rubber stopper is immersed in an alkaline solution with one end of the tube. The other end of the tube is connected to the outlet of the microwave chamber with a hose. During heating, the sample emitted a lot of fumes and these fumes were passed into the NaOH solution. The sample was heated to 1100 °C within 5 minutes using a single die. The temperature of the outer surface of the crucible was measured with a pyrometer. The temperature was mainta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com