Piezoelectric substrate for surface acoustic wave device and surface acoustic wave device

A surface elastic wave, piezoelectric substrate technology, applied in electrical components, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as miniaturization limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0135] Next, examples of the surface acoustic wave device of this embodiment will be described. First, a method of manufacturing the piezoelectric substrate 1 for a surface acoustic wave device of this embodiment will be described. The material of the piezoelectric substrate 1 is to use a point group 32 with Ca 3 Ga 2 Ge 4 o 14 type crystal structure; its main components are composed of Ca, Nb, Ga, Si and O, and it is composed of the chemical formula Ca 3 NbGa 3 Si 2 o 14 represents a single crystal. The growth of single crystal is carried out by the CZ method of high-frequency heating, that is, the rotary pulling method. A substrate 1 for a surface acoustic wave device was prepared by cutting out a substrate from the obtained single crystal using the cutting angle described below.

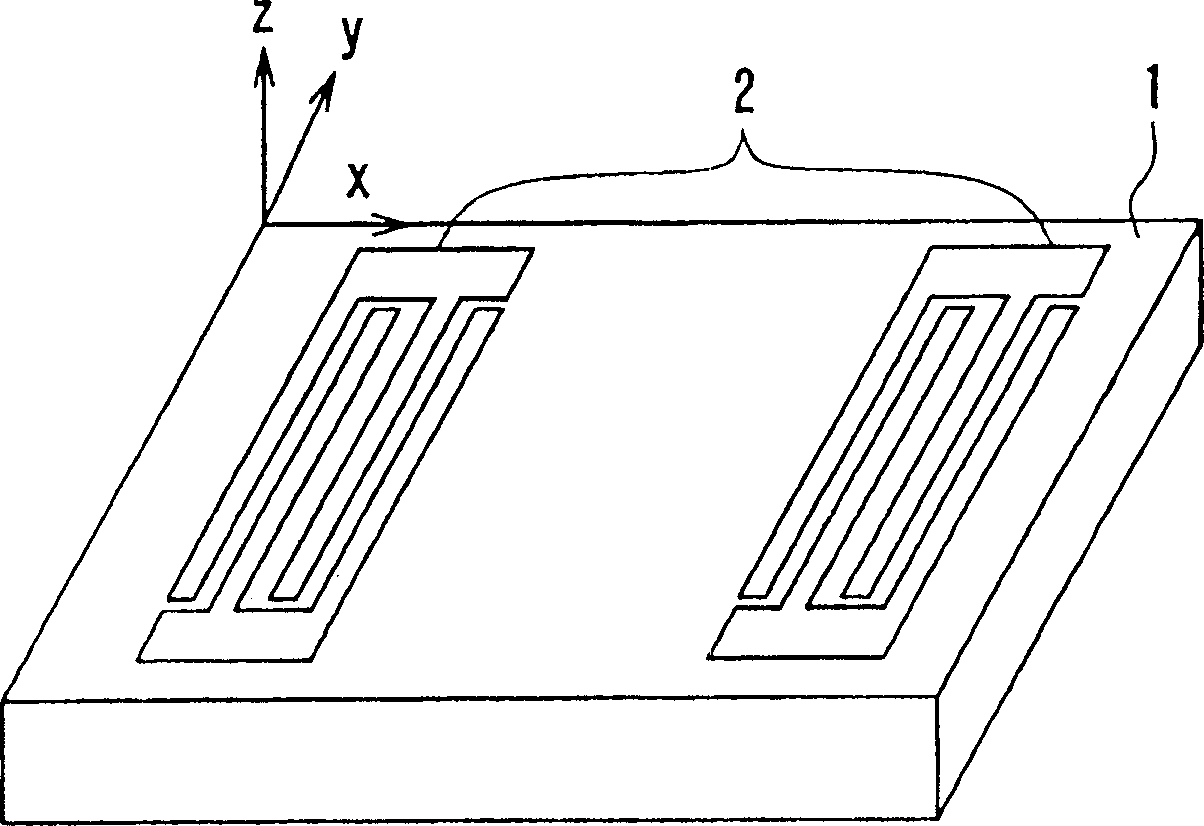

[0136] Next, a method of fabricating a surface acoustic wave device for a test will be described. As shown in FIG. 1 , in the surface acoustic wave device for testing, interdigitated ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com