Quasi-synchronous reluctance motor

A reluctance motor, quasi-synchronous technology, applied in the direction of electrical components, electromechanical devices, etc., can solve the problems of increasing the cost of the drive system and low power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

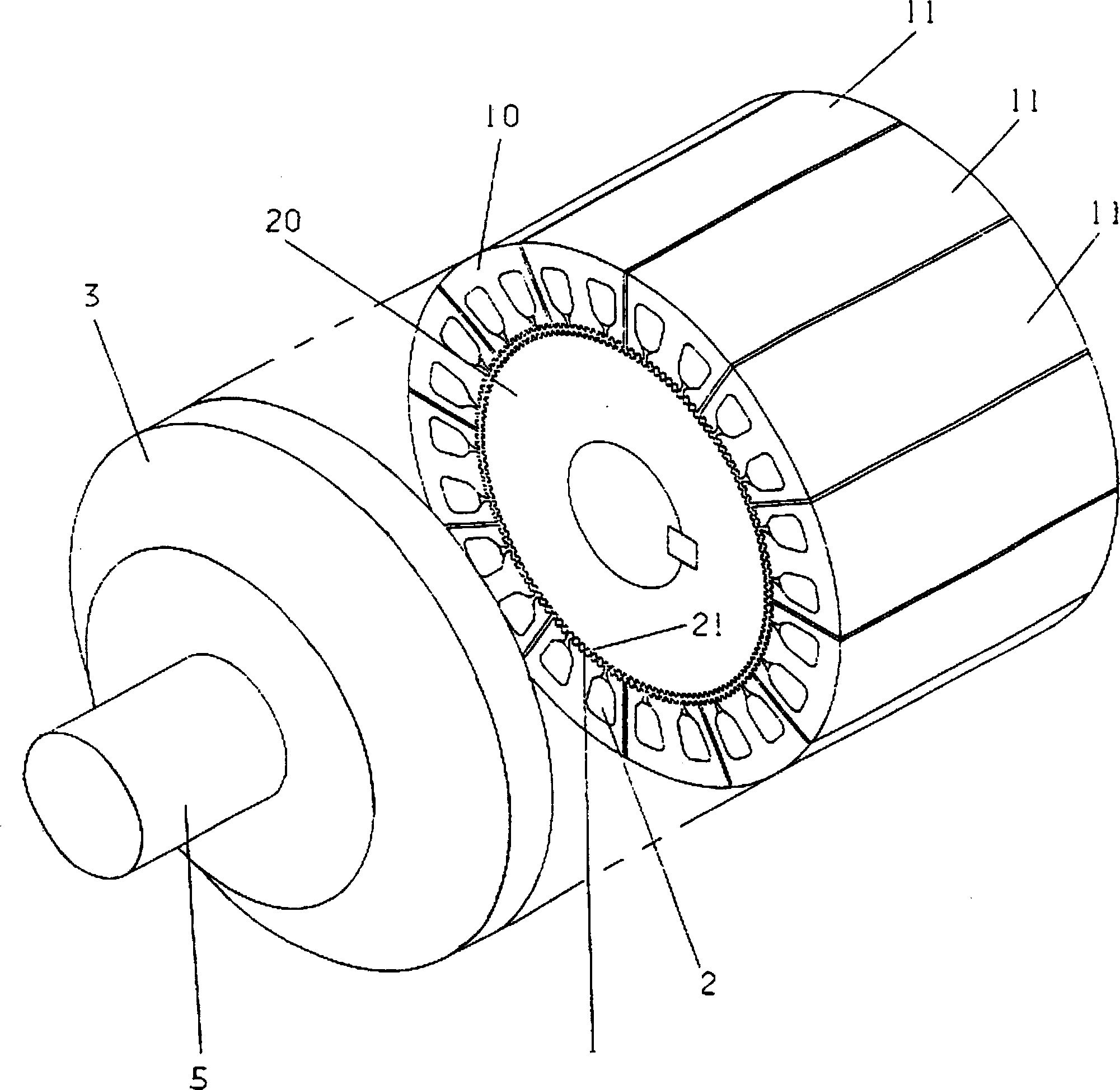

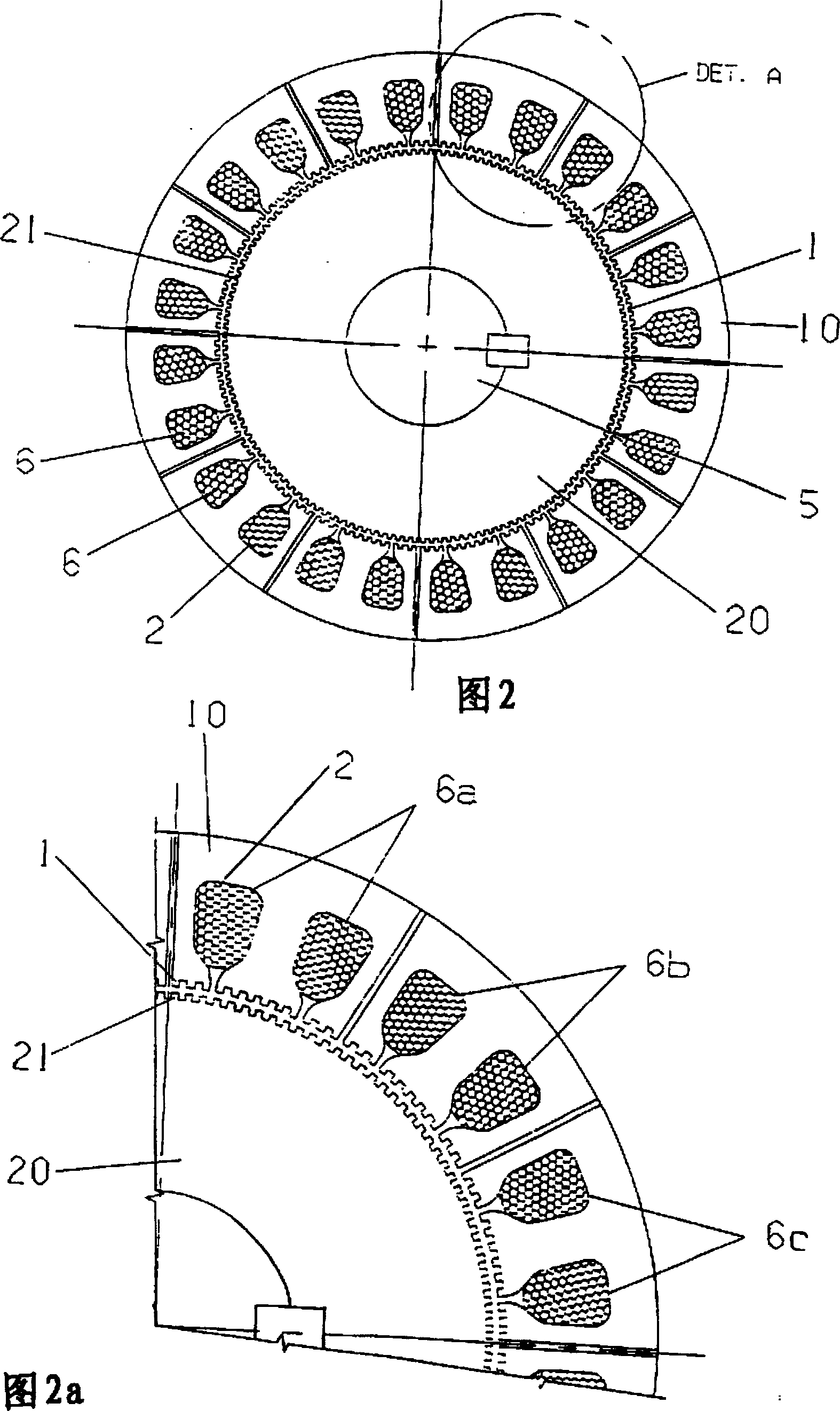

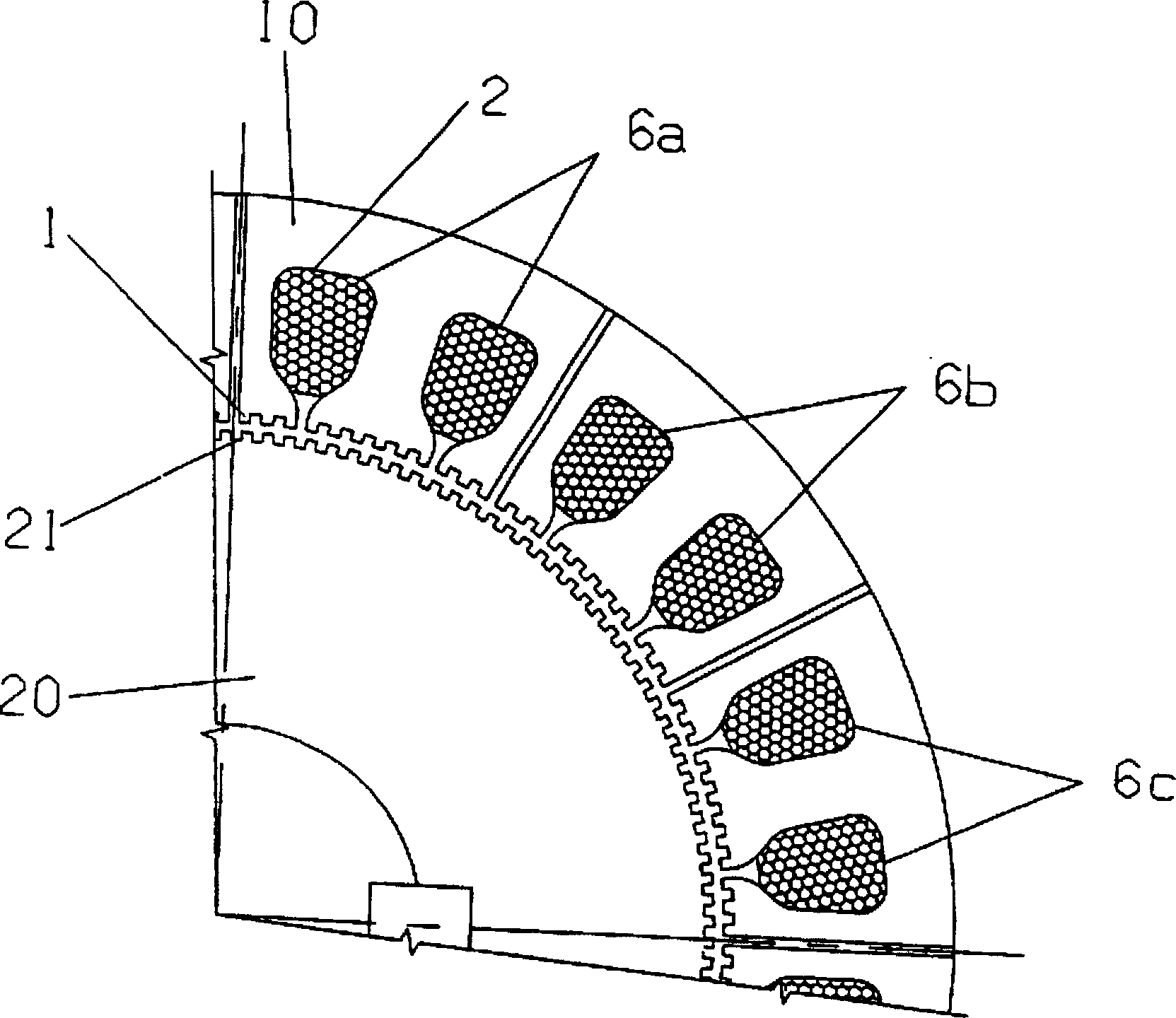

[0033] According to the above-mentioned drawings, the quasi-synchronous reluctance motor constituted according to the concept of the present invention is constructed according to such a stator 10, which has a ferromagnetic material sheet made of non-magnetic coupling or weak magnetic coupling A core consisting of segments 11 having longitudinal teeth 1 arranged on its surface facing said rotor 20 and slots 2 formed for accommodating one or more windings 6 .

[0034] These windings 6 comprise coils of magnetic material surrounding the stator 10 in order to generate a magnetic field when this winding is energized.

[0035] Since the integral part of the quasi-synchronous reluctance motor is the rotor 20, the rotor 20 also includes an iron core composed of some ferromagnetic material sheets, and longitudinal teeth 21 are evenly arranged along the end face turned to the stator 10. The teeth The number of 21 is different from the number of teeth 1 on the stator 10 .

[0036] more ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com