Solar energy evaporating type separation method and apparatus therefor

A separation method, evaporative technology, applied in the direction of separation method, evaporation, chemical instruments and methods, etc., to achieve the effect of simple structure design, conducive to material separation, and prevent energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

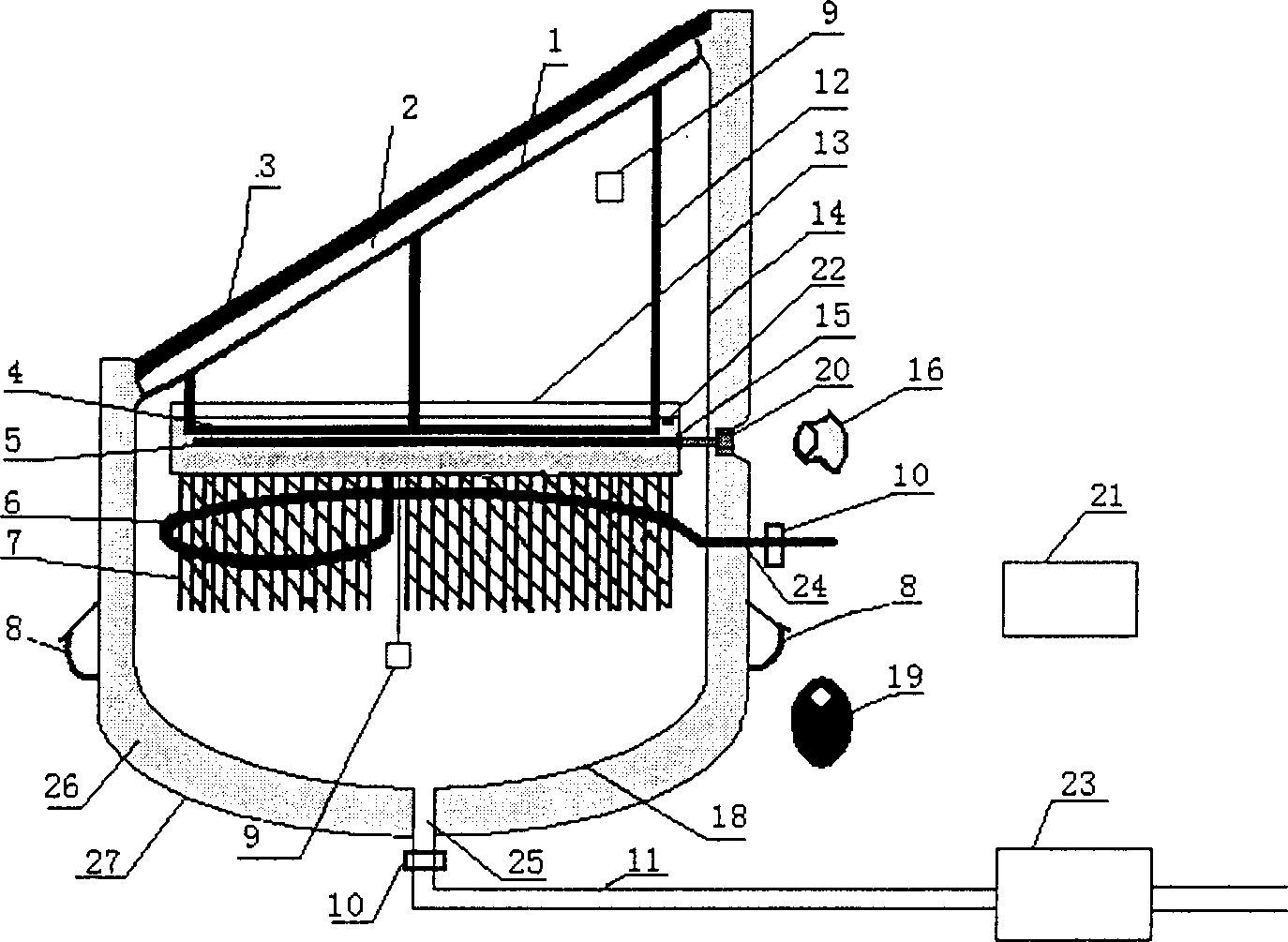

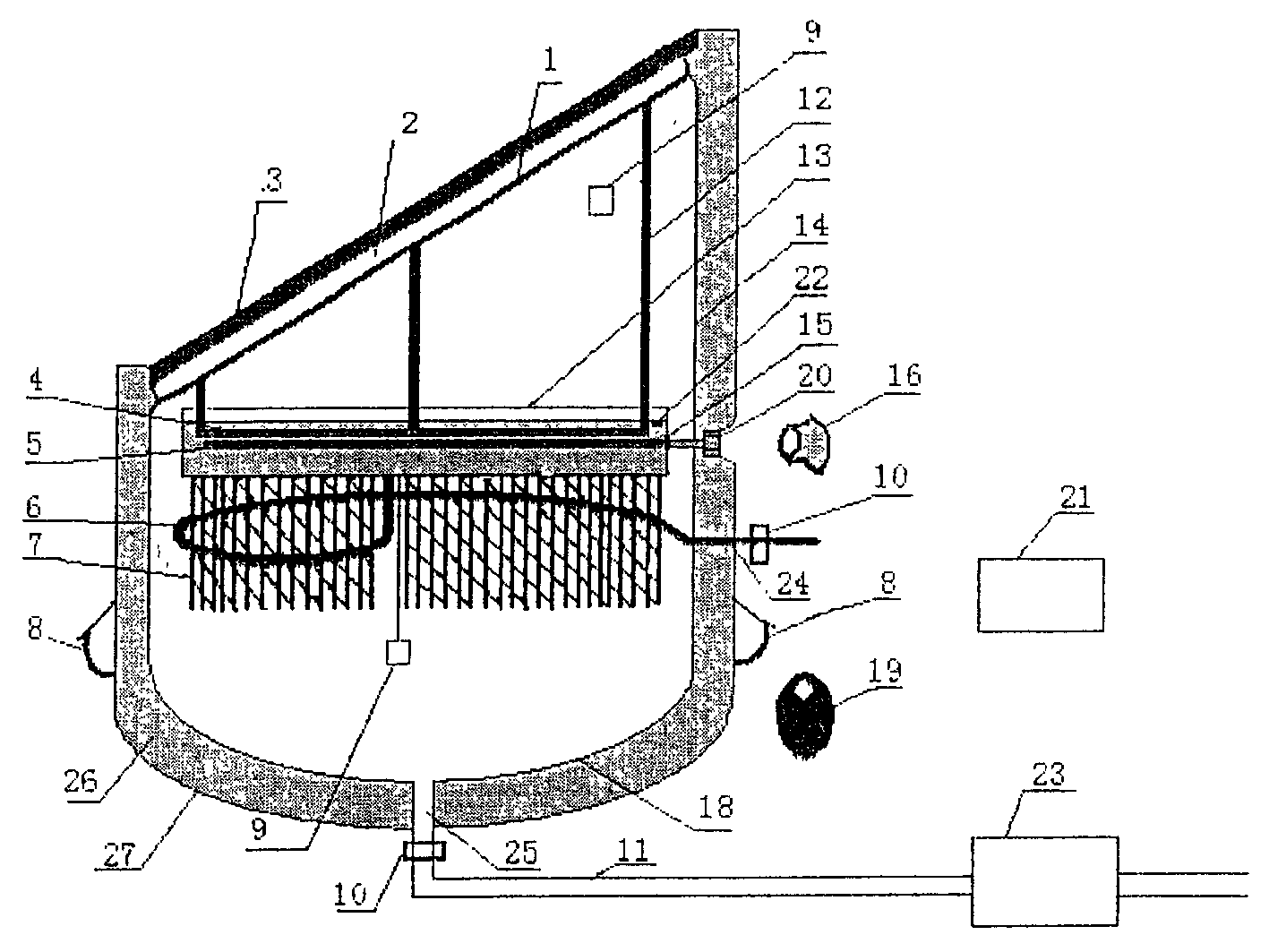

[0017] Try it out in the ocean as an example:

[0018] Use solar absorbing material (asphalt) to absorb solar radiation energy into the heat-insulating device. In order to avoid energy loss, the device adopts a heat-insulating and airtight structure. The energy absorbed by the device is used to heat the material to be separated, so that its surface temperature rises locally. High, to increase the evaporation rate of the substance and its saturated vapor pressure in the device, but due to the large difference in the saturated vapor pressure between the substances in the substance to be separated, the components of the steam are dominated by those with high saturated vapor pressure. At the same time, The steam needs to condense and liquefy on all sides of the device, and the liquefaction process condenses faster on surfaces with lower temperatures, and the condensed substances on these surfaces will be directed to flow into the collection container, thus realizing the evaporation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com