Anti-shock device

A technology of anti-seismic devices and components, applied in the direction of anti-seismic, building components, building structures, etc., to achieve the effects of increasing torsional stiffness, reducing directionality, and preventing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

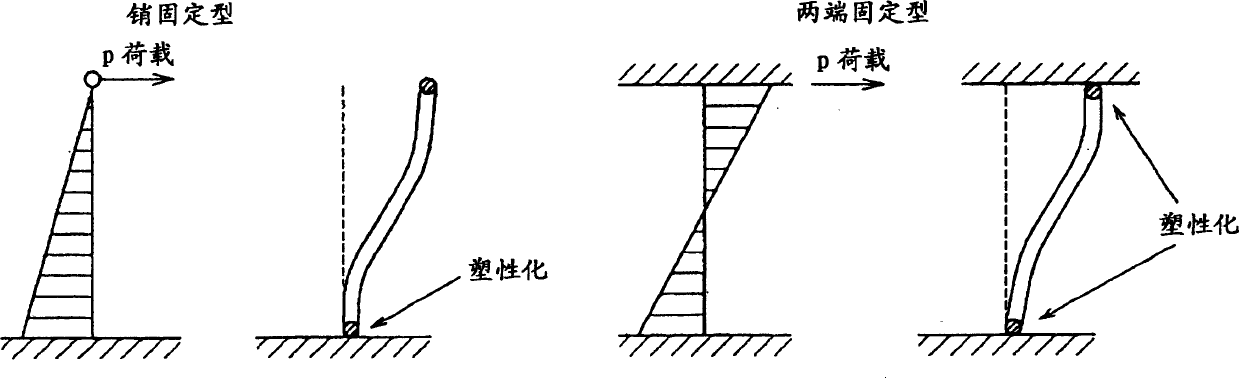

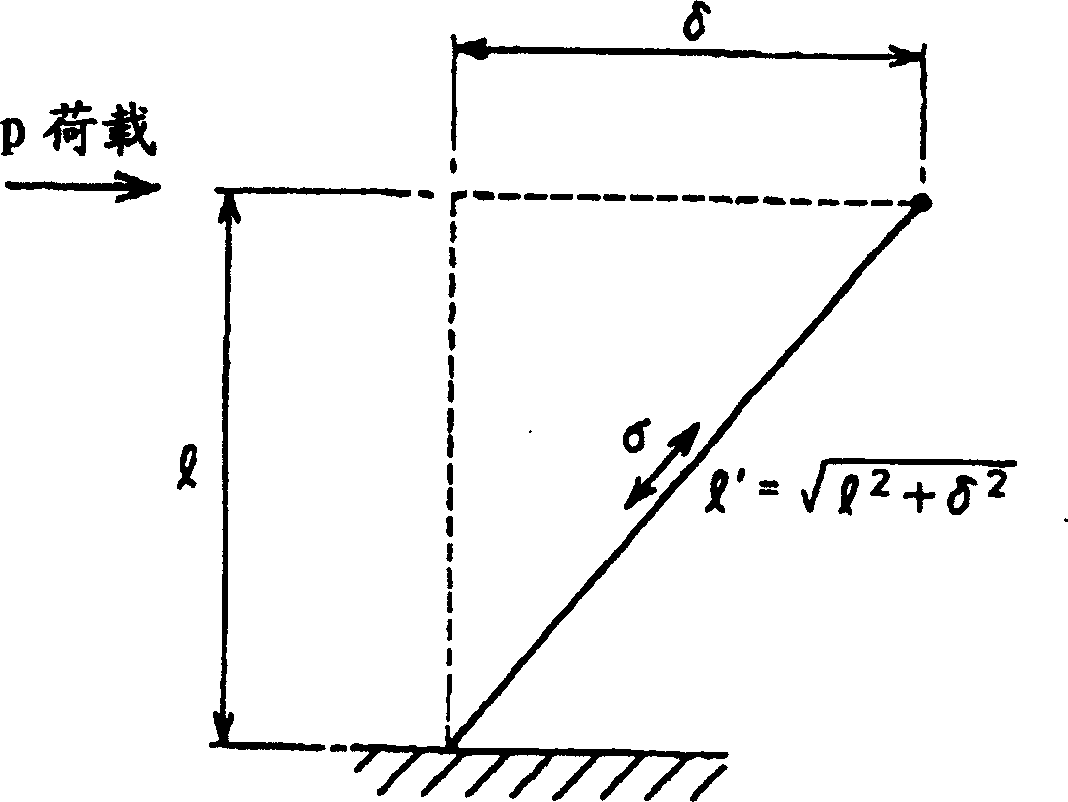

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

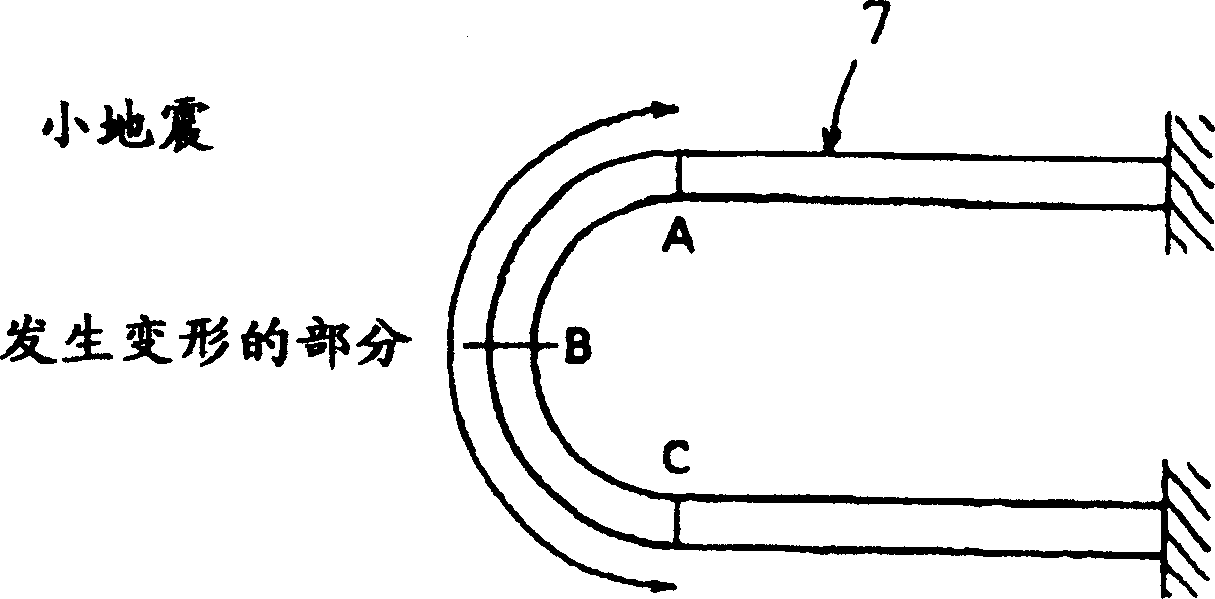

[0129] Fig. 6 shows an embodiment of the present invention. In this embodiment, an attenuation mechanism 6 is provided between the upper structure 2 and the bottom structure 3 interposed with the isolator 1 . The attenuation mechanism 6 adopts a plurality of curved parts 7 formed from elastic-plastic materials into a substantially U-shape as shown in FIG. In this way, two curved members are combined to form a set, and a plurality of sets of such sets are used. As shown in FIG. 9, the curved member 7 is, for example, made of elastoplastic material, and a steel material with a rectangular cross-section of 25 mm in length and 50 mm in width is formed into a curved shape. After forming, if necessary, heat treatment is performed to remove residual deformation. The installation part 8 at one end of the corresponding curved part 7 is fixed on the upper structure 2 , and the installation part 9 at the other end is fixed on the bottom structure 3 .

[0130] In addition, when the atte...

no. 2 Embodiment

[0147] Fig. 18 shows an embodiment of the present invention. This embodiment is the following anti-seismic device, wherein, on the outer periphery of the isolator 1 sandwiched between the upper structure 2 and the bottom structure 3, a curved member 7 constituting the damping mechanism 6 is provided, and the isolator 1 and the curved member 7 set integrally. As shown in Figure 19, on the outer periphery of the connecting plate 14 connecting the isolator 1, the isolator with the upper structure 2 and the bottom structure 3, two or more of them are curved and are formed of elastic-plastic materials. Components 7 are circular as shown in Figure 20 and Figure 21, arranged at equiangular intervals, and combined in a lantern shape, or as shown in Figure 22 and Figure 23, two curved components 7 are line-symmetric Combined in different ways, thus forming a group, and the multiple groups of components are arranged on the outer periphery of the isolator 1 . In the process of installi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com