Ultrasonic cleaning apparatus and ultrasonic claning method

A cleaning device and ultrasonic technology, applied in cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as large loss of ultrasonic waves, difficulty in ultrasonic cleaning, and large loss of cleaning liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

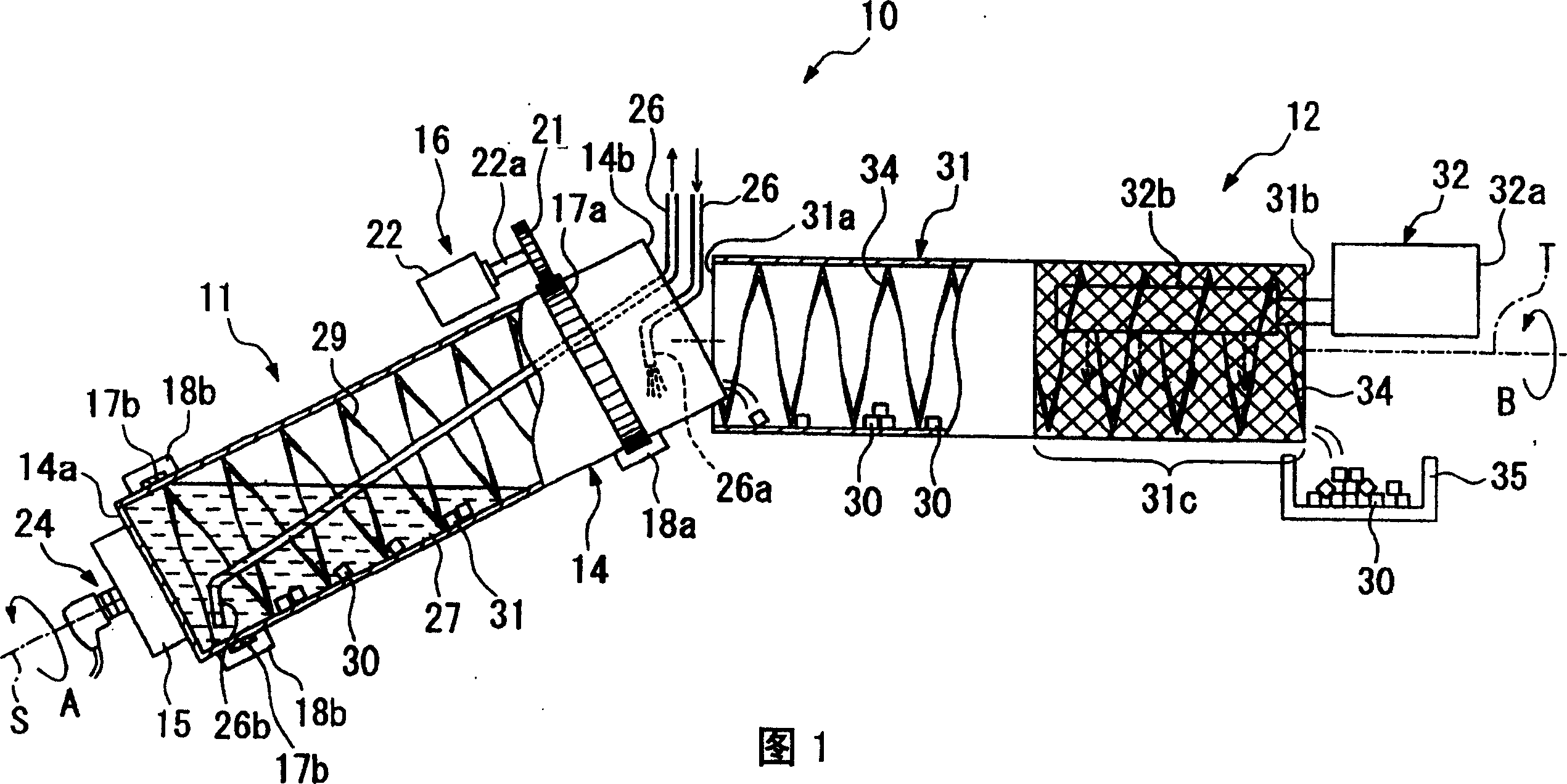

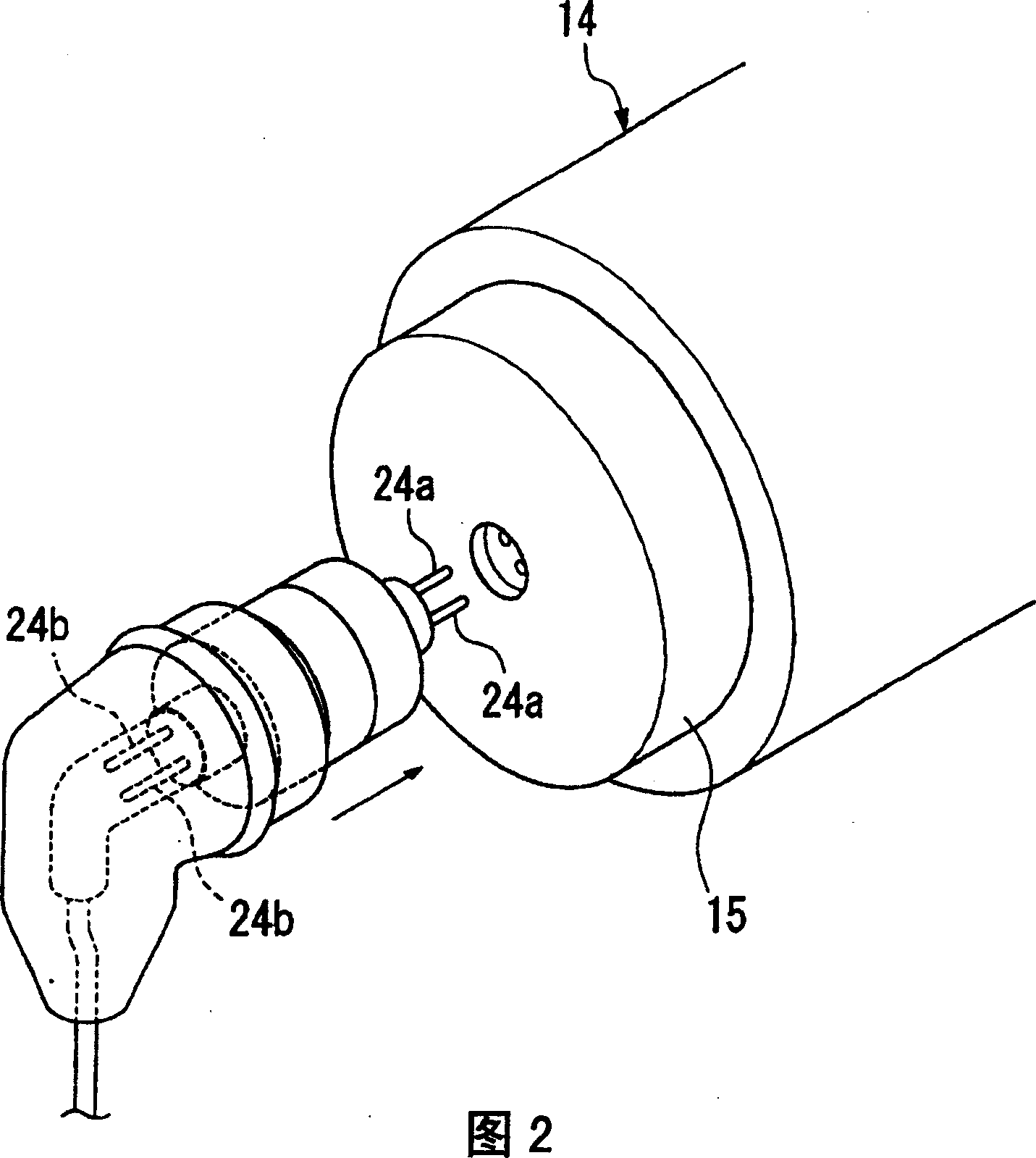

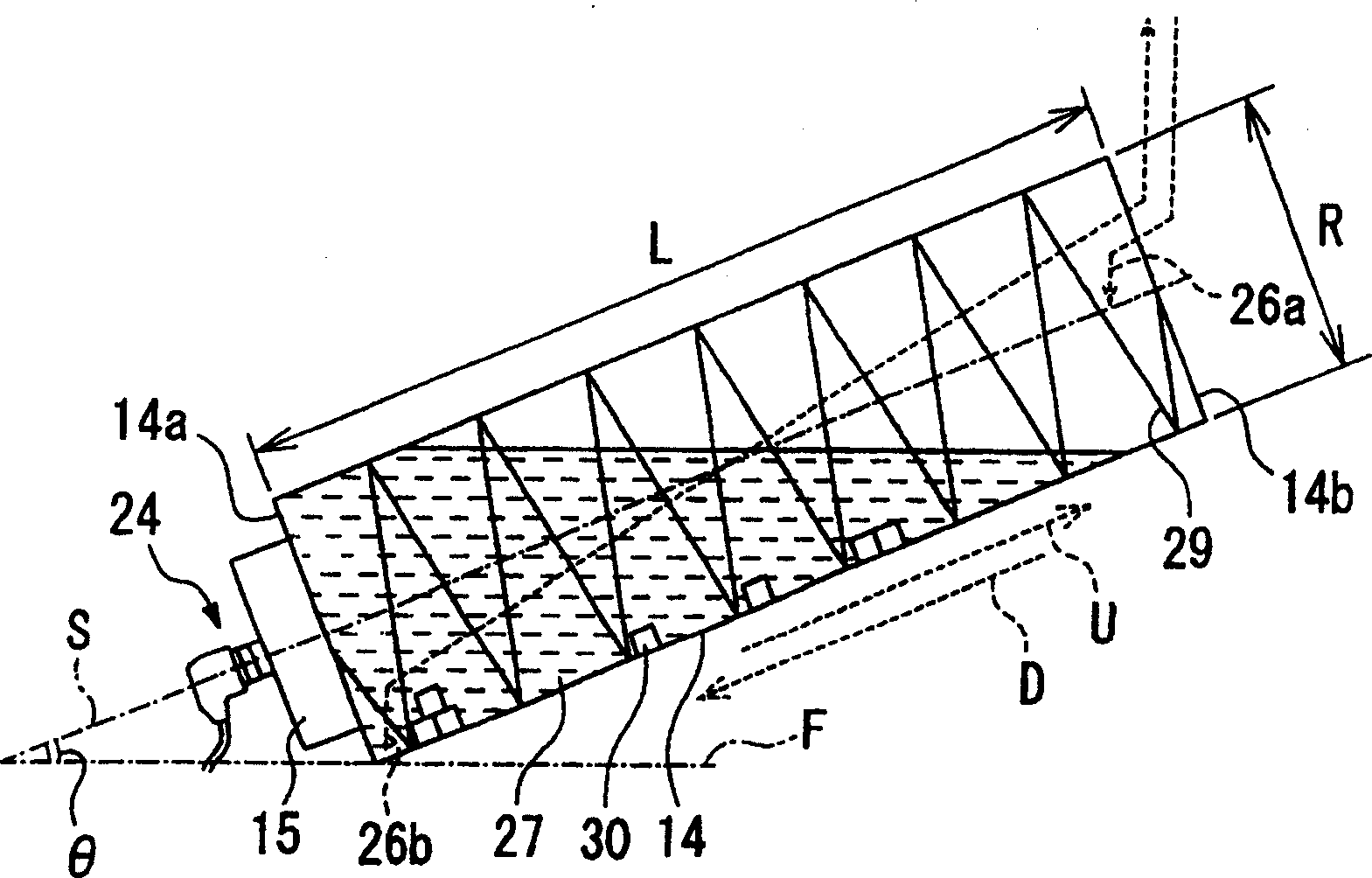

[0022] Embodiments of the present invention will be described below with reference to the accompanying drawings. Fig. 1 is a sectional view showing a part of an ultrasonic cleaning device according to the present invention. The ultrasonic cleaning device 10 has a cleaning unit 11 and a drying unit (drying device) 12 . The cleaning unit 11 is composed of a cleaning cylinder 14 , an ultrasonic vibration unit (ultrasonic wave generation mechanism) 15 and a rotation mechanism (rotation device) 16 . The cleaning cylinder 14 is a substantially cylindrical cleaning tank with one end (bottom surface side) 14a having a closed side and the other end 14b being open, inclined relative to the horizontal plane, and is made of, for example, stainless steel.

[0023] Racks 17a, 17b are provided around the outer circumferential surface on both sides of the lengthwise direction of the cleaning cylinder 14. On the outside of the cleaning cylinder 14, there is formed a rack that is slidably conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com