Process for direct reduction of lead from high content of liquid lead dreg in bottom blowing furnace

A technology of high-lead slag and bottom-blown furnace, applied in the field of direct reduction of lead smelting with high-lead slag in bottom-blown furnace, can solve problems such as difficult operation in the reduction section, energy waste, high-tech level requirements, etc., and achieve simple and reliable production process, The effect of reducing equipment investment and small flue gas volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

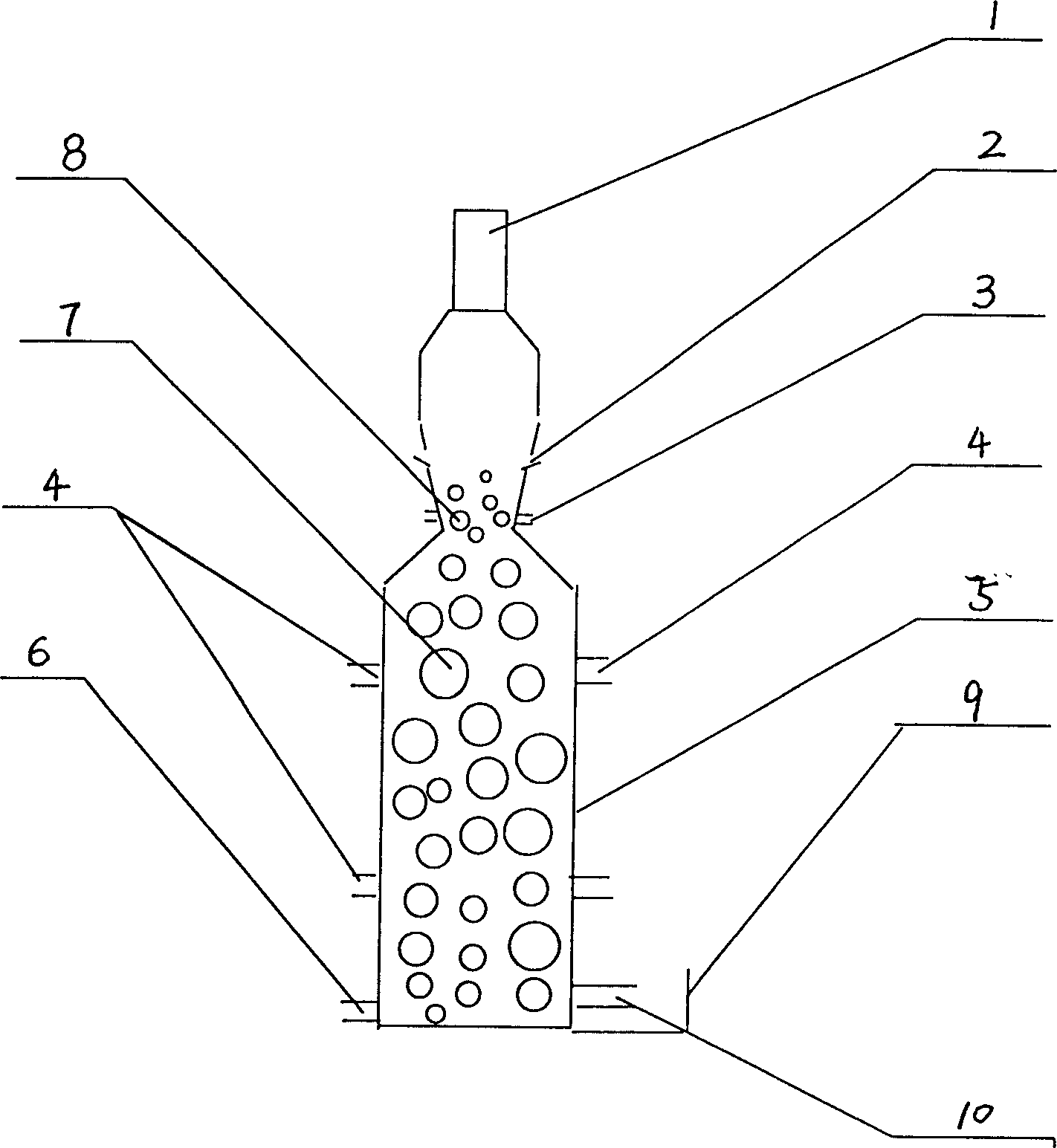

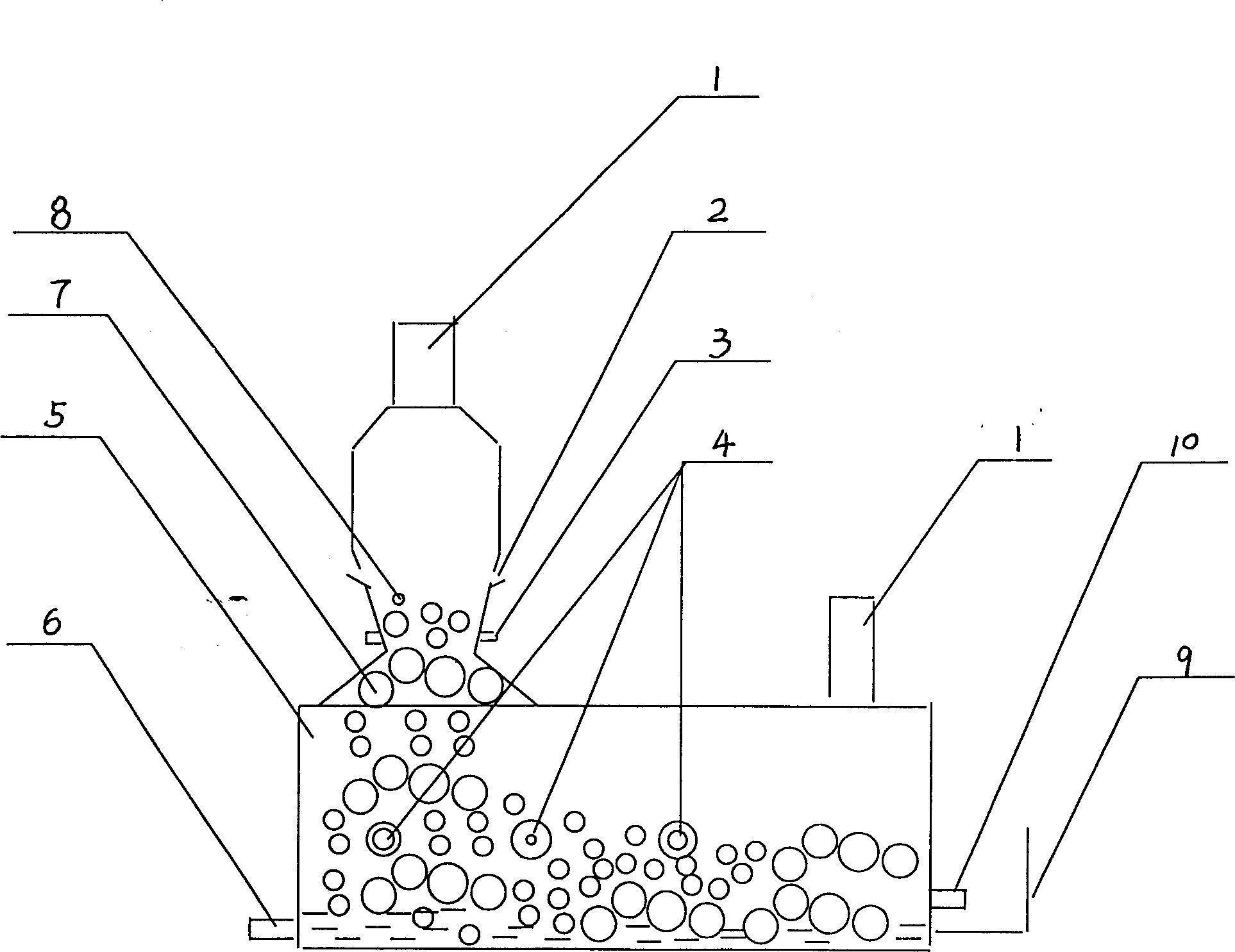

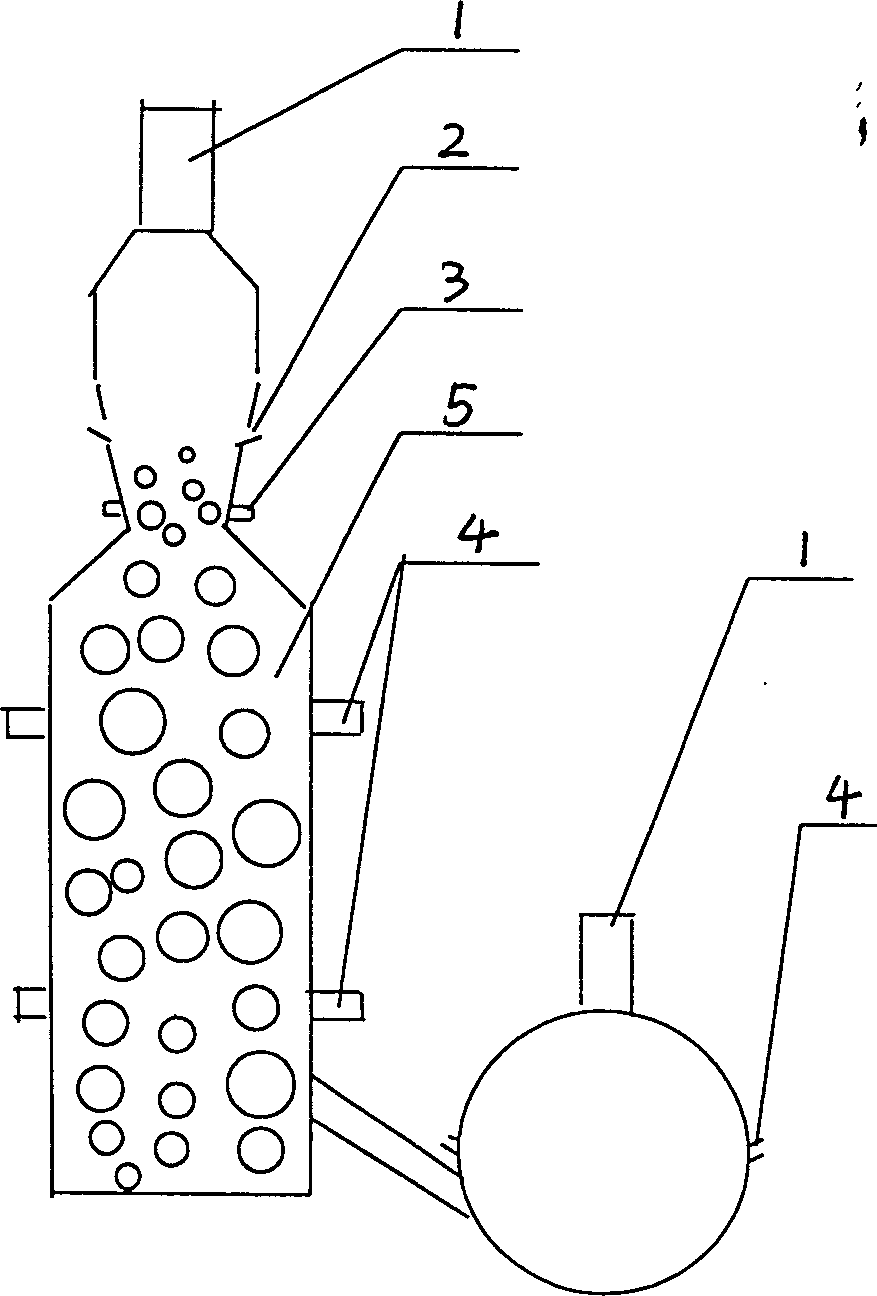

[0010] Such as figure 1 As shown, the present invention directly injects the high-lead slag released from the oxidation smelting of the bottom blowing furnace into the reduction furnace for reduction smelting, simultaneously adds pulverized coal or coke into the reduction furnace, and feeds air, pulverized coal or The heat released by the reaction of coke and air and the produced CO gas react with the high-lead slag PbO injected into the reduction furnace to generate metallic lead.

[0011] Such as figure 1 , 2 , Shown in 3, 4, reduction furnace of the present invention adopts vertical furnace, also can adopt horizontal furnace, can also adopt horizontal and vertical combined furnace.

[0012] 1. Shaft furnace: the reduction furnace is a shaft furnace, including a furnace shell 5, a smoke outlet 1 arranged on the furnace shell 5, a coke inlet and a liquid high-lead slag melt inlet 2, and a furnace shell 5 The upper combustion-supporting tuyeres 3, the main tuyeres 4 arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com