Oil-submersible pump

A technology of submersible oil pump and pump casing, which is applied in the field of liquid conveying device, can solve the problems that motor shaft bearing cannot be lubricated well, the reliability and safety of pump and motor are affected, and the reliability and safety of pump operation are not good. , to achieve the effect of improving reliability and safety, simple structure and obvious cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

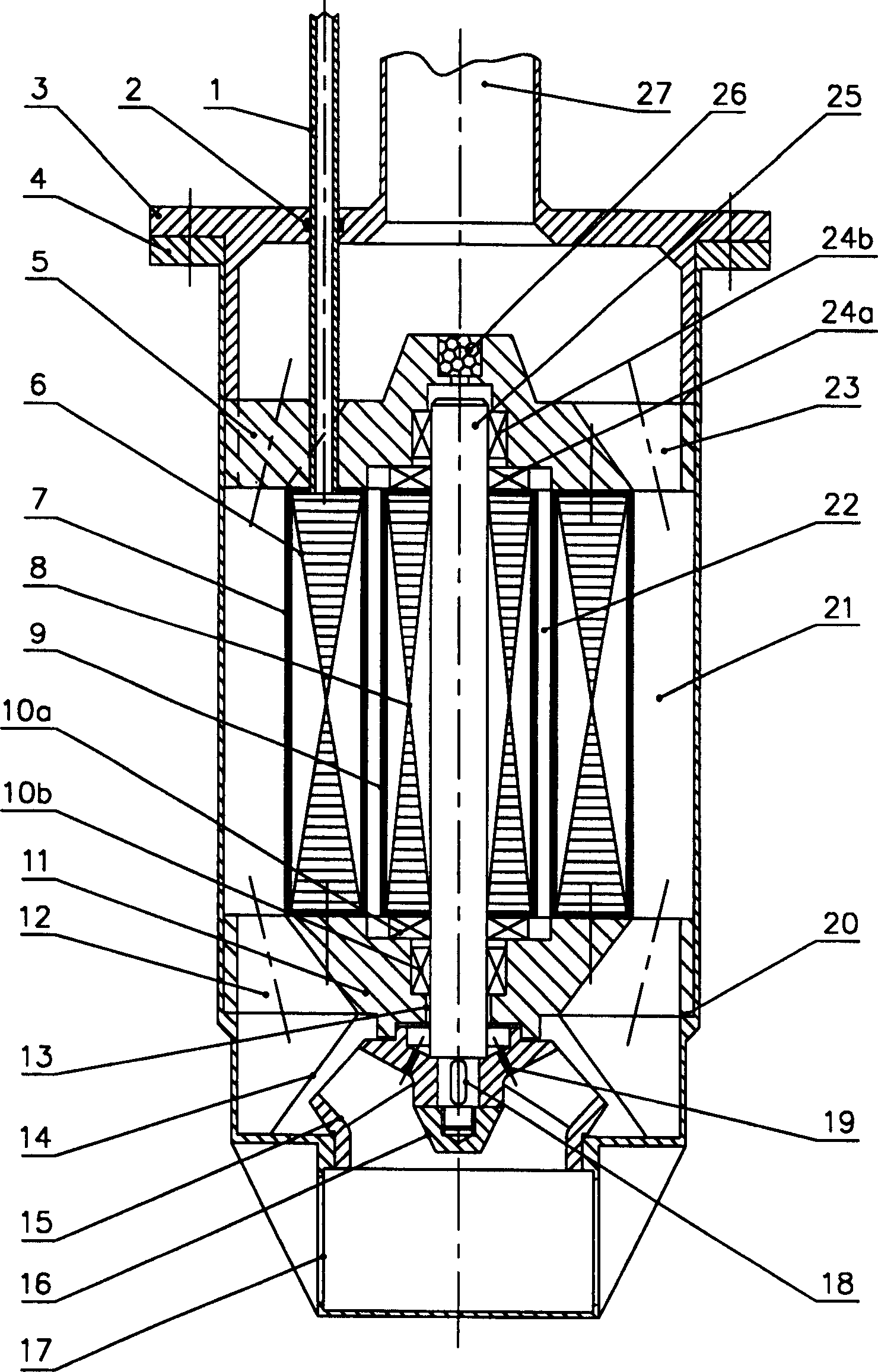

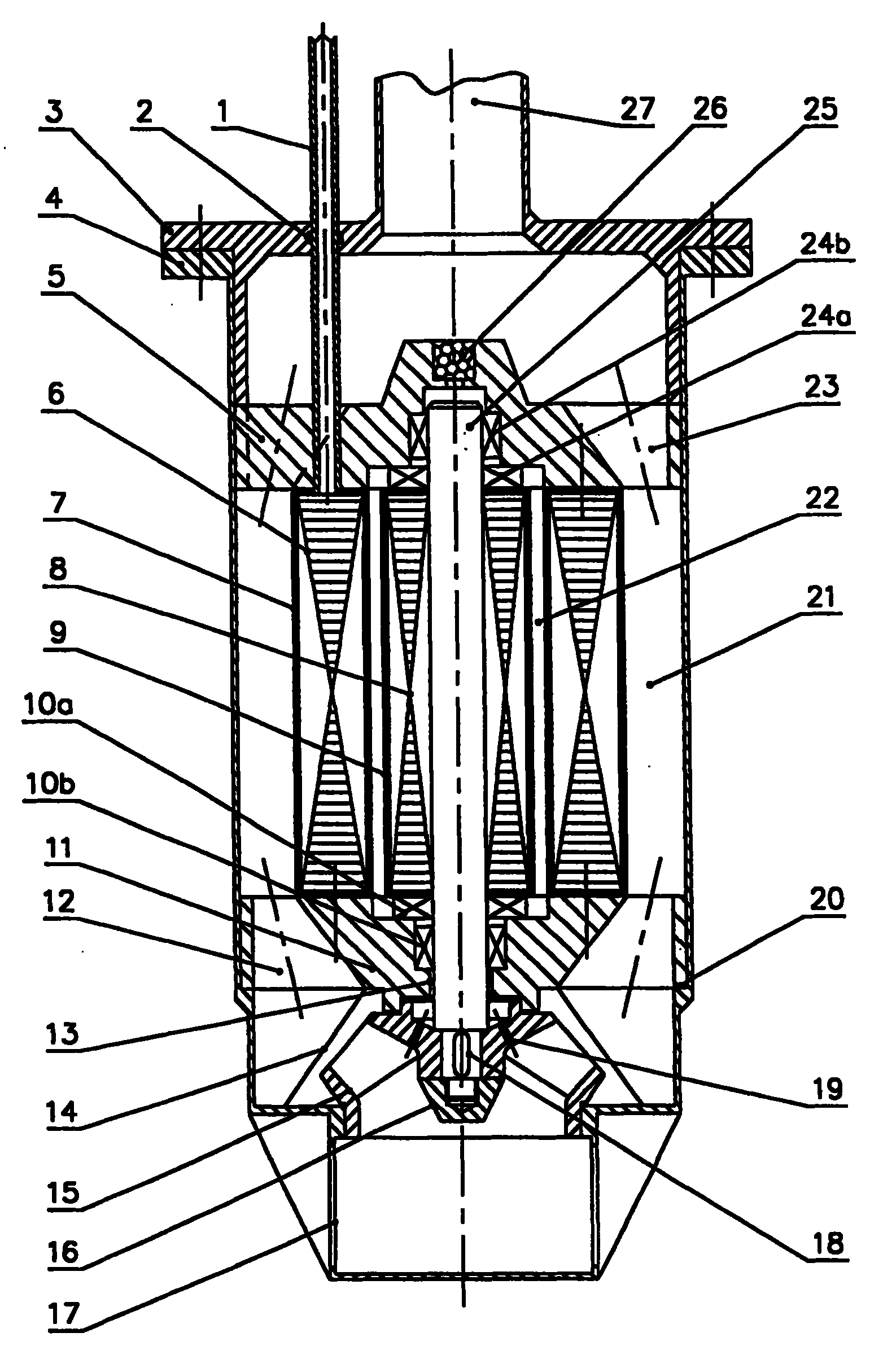

[0016] As shown in the figure, the present invention mainly includes a pump casing 4, a motor stator 6, an integrated motor rotor 8, a motor shaft 25, and an impeller 15 on the motor shaft; wherein the lower end of the pump casing 4 has a horizontal liquid inlet 17; the pump There is a step 20 on the inner wall of the shell, and the lower bearing seat 11 is positioned on the step 20; the lower end of the motor shaft 25 is positioned on the lower bearing seat 11 by the lower axial bearing 10a and the lower radial bearing 10b, and is connected with the impeller located on the lower side of the lower bearing seat. 15 is connected with the nut 16 through the key 18, and the upper end of the motor shaft 25 is positioned on the upper bearing seat 5 by the upper axial bearing 24a and the upper radial bearing 24b; 5 and the lower bearing seat 11 are fixed, an outer ring channel 21 is formed with the pump casing 4, and an inner ring channel 22 is formed between the motor rotor 8; the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com