Transfer sheet material

A technology of transfer sheet and transfer layer, applied in transfer printing method, transfer ink from manuscript, printing, etc., can solve the problems of insufficient conveying stability and contamination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

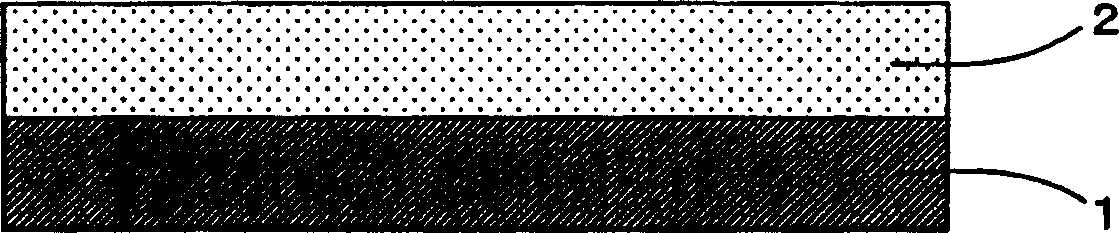

Image

Examples

Embodiment 1 to 2 and comparative example 1 to 6

[0173] An aqueous coating solution (coating agent) was prepared by mixing the components given in Table 1 in the proportions given in Table 1 (on a solid basis). The aqueous coating solution is 37g / m 2 A coating amount of , was applied on coated paper (manufactured by lintec Corporation BK6RB (S5)), and dried at 80°C, whereby a transfer sheet composed of the transfer layer in Table 1 was obtained. The evaluation results of the obtained transfer sheets are shown in Table 1.

[0174] Example

[0175] It can be seen from Table 1 that the properties of the transfer sheets of Examples 1 to 2 are well balanced. In contrast, since the transfer sheets of Comparative Examples 1 to 6 did not include the three types of nylon fine particles, these sheets were poor in each property balance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| oil absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com