Starter for engine

An engine starting and motor shaft technology, which is applied in the directions of engine starting, electromechanical devices, engine components, etc., can solve problems such as shortening of clutch life and noise, and achieve the effect of suppressing noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

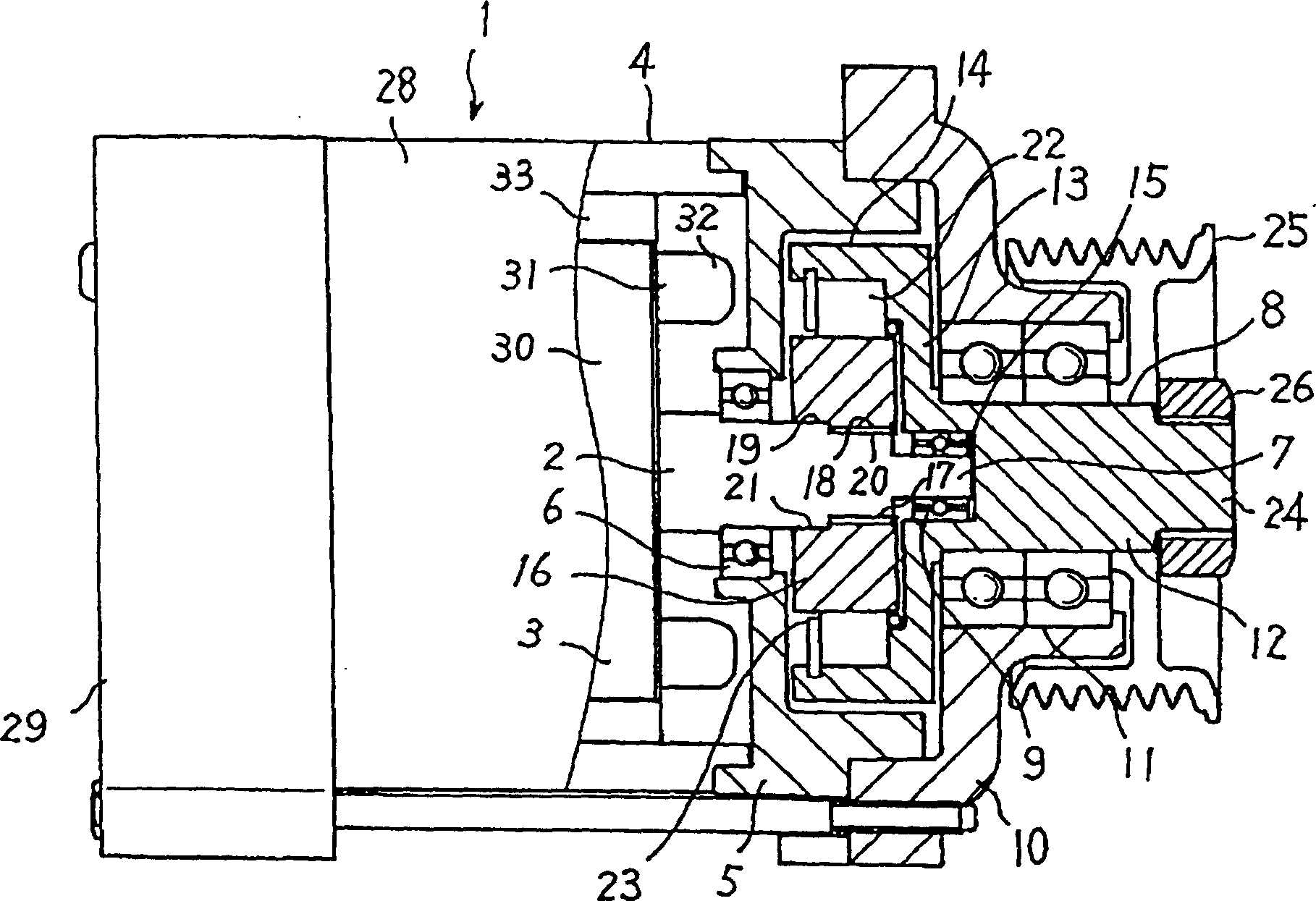

[0013] figure 1 It is a longitudinal sectional view showing the engine starting device according to Embodiment 1 of the present invention. In the figure, the motor 1 has a motor body 28 and a rotatable motor shaft 2 extending from the motor body 28 . The motor main body 28 has the armature 3 which rotates integrally with the motor shaft 2, and the stator 4 which surrounds the armature 3 with a gap. The motor shaft 2 is rotatably supported on the motor shaft bracket 5 through the bearing 6 . A motor shaft bracket 5 is mounted on the stator 4 .

[0014] In addition, the motor shaft 2 is also rotatably supported by a rear frame 29 arranged on the side opposite to the motor shaft bracket 5 of the motor 1 .

[0015] The armature 3 has an armature core 30 coaxially fixed to the motor shaft 2 and an armature coil 31 disposed on the outer peripheral portion of the armature core 30 . The armature coil 31 has a coil terminal 32 extending in the axial direction of the motor shaft 2 ....

Embodiment 2

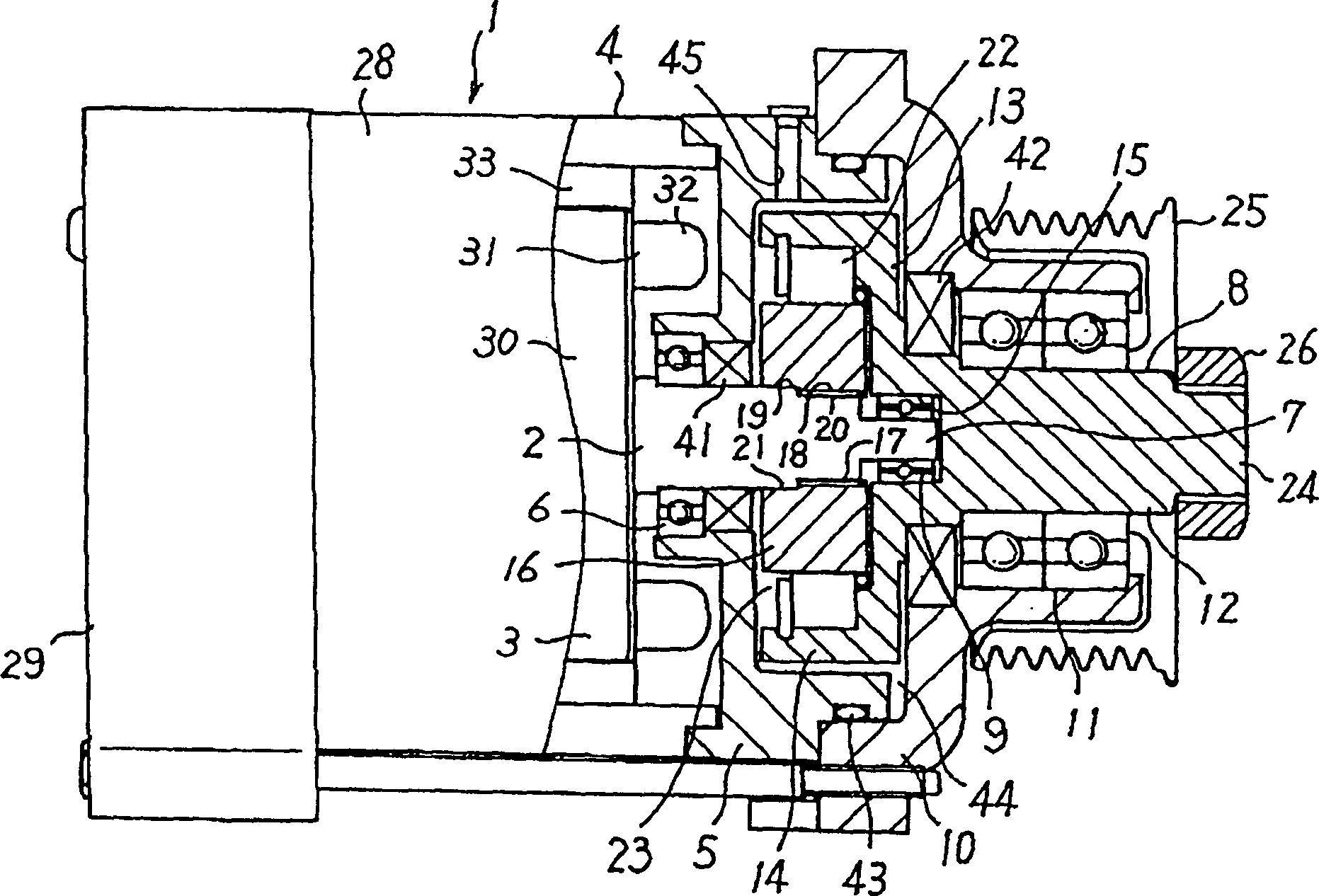

[0040] figure 2 It is a longitudinal sectional view showing an engine starting device according to Embodiment 2 of the present invention. In the figure, sealing members 41 and 42 are disposed between the motor shaft 2 and the motor shaft bracket 5, between the output shaft 8 and the output shaft bracket 10, and between the motor shaft bracket 5 and the output shaft bracket 10. , 43. The seal member 41 is disposed between the bearing 6 and the interior 16 . The seal member 42 is disposed between the bearing 11 and the extension 13 . The seal member 43 is disposed on a portion around the outer portion 14 where the motor shaft bracket 5 and the output shaft bracket 10 are fitted together.

[0041] Oil is stored in a space 44 surrounded by the motor shaft bracket 5 and the output shaft bracket 10 . Oil is stored at least to the extent that it impregnates a portion of the exterior 14 . Oil is prevented from leaking out by the sealing members 41 , 42 , and 43 . Furthermore, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com