Photoconductor drum, drive shaft, photoconductor drum system, image-forming apparatus, and multifunction apparatus

一种感光体鼓、驱动轴的技术,应用在应用电荷图形的电记录工艺、应用电荷图形的电记录工艺的设备、光学等方向,能够解决影响振摆精度等问题,达到容易插拔的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0079] Embodiments of the present invention will be described in detail below.

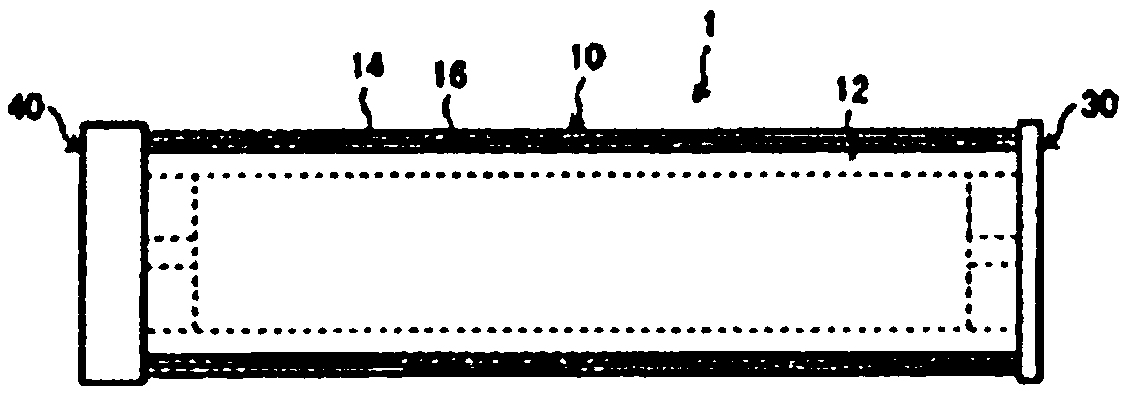

[0080] figure 1 A schematic diagram of the photoreceptor drum of this embodiment is shown in .

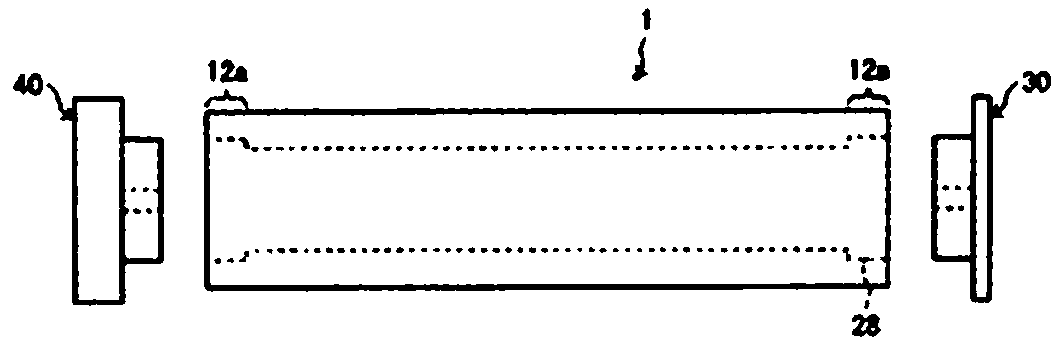

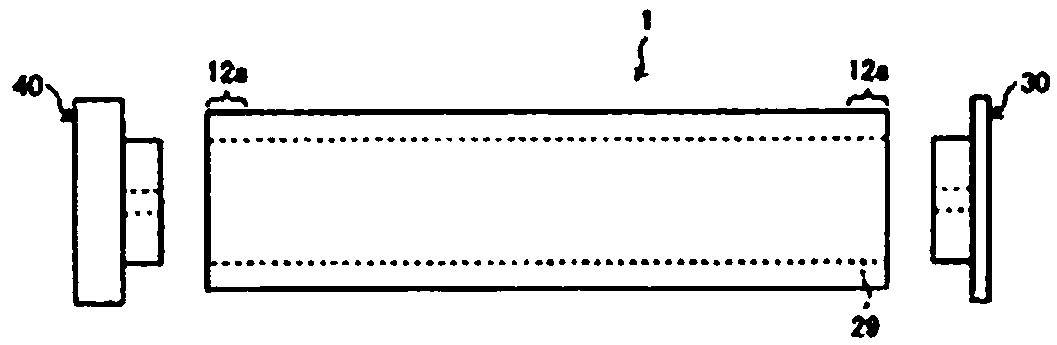

[0081] like figure 1 As shown, the photoreceptor drum 1 includes a drum main body 10, front flanges (hereinafter referred to as "F flanges") 30 fitted to both ends of the drum main body 10, and rear flanges (hereinafter referred to as "R flanges"). 40.

[0082] The drum main body 10 includes a cylindrical conductive support 12 , an intermediate layer (also referred to as “primer layer”) 16 coated on its outer peripheral surface, a photosensitive layer 14 , and the like. The F flange 30 is a flange located on the front (F) side in a state where the photoreceptor drum 1 is mounted on the image forming apparatus. The R flange 40 is a flange located on the rear (R) side of the image forming apparatus in which the driving system of the image forming apparatus is disposed in the aforementioned state. He...

Embodiment 1

[0199] The shaft support portion of the flange of Example 1 adjusted the diameter of the inner peripheral surface so that a gap of 20 micrometers was generated between the inner peripheral surface thereof and the outer peripheral surface of the drive shaft. Table 1 is a list of conditions and evaluation items of Examples 1 to 5 and Comparative Examples 1 to 5. Additionally, if Figure 11A As shown in Table 1, three fitting protrusions with a height of 40 μm were provided at uniform angles along the circumferential direction on the inner peripheral surface.

[0200] [Table 1]

[0201]

[0202]

Embodiment 2

[0204] The shaft support portion of the flange of Example 2 was the same as that of Example 1, and the diameter of the inner peripheral surface was adjusted so that a gap of 20 μm was formed between the inner peripheral surface and the outer peripheral surface of the drive shaft. Additionally, if Figure 11B As shown in Table 1 and Table 1, in Example 1, two sets of fitting protrusions with a height of 40 μm provided on the shaft supporting portion are provided in two sets in the axial direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com