A quick and flexible bonding and sealing machine for poct real-time detection chip products

A technology for detecting chips and sealing machines, applied in material gluing, connecting components, mechanical equipment, etc., can solve the problems of affecting chip sealing, time-consuming, and chips are prone to bubbles, etc., to improve the degree of automation, optimize process parameters, Good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

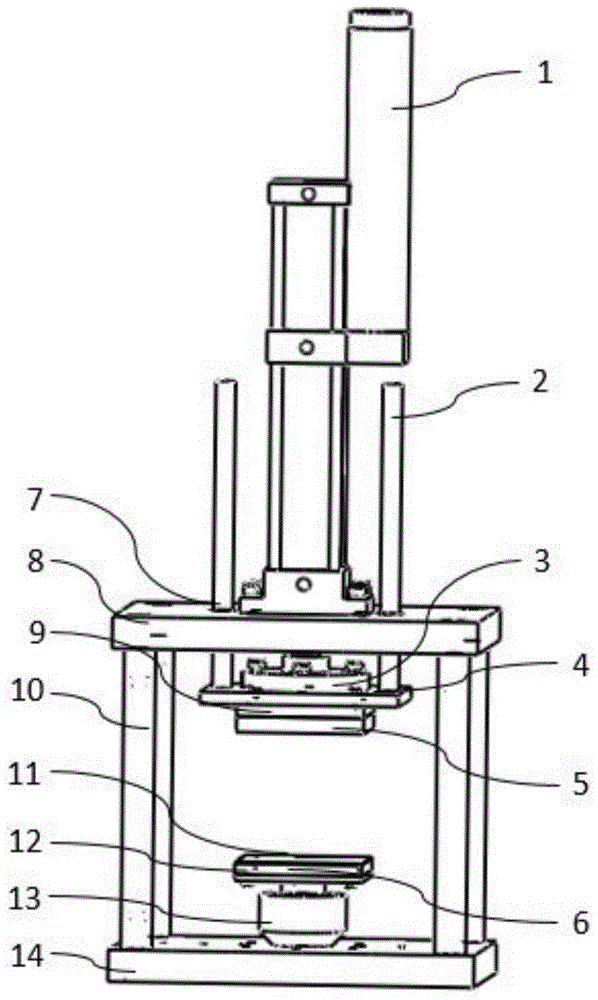

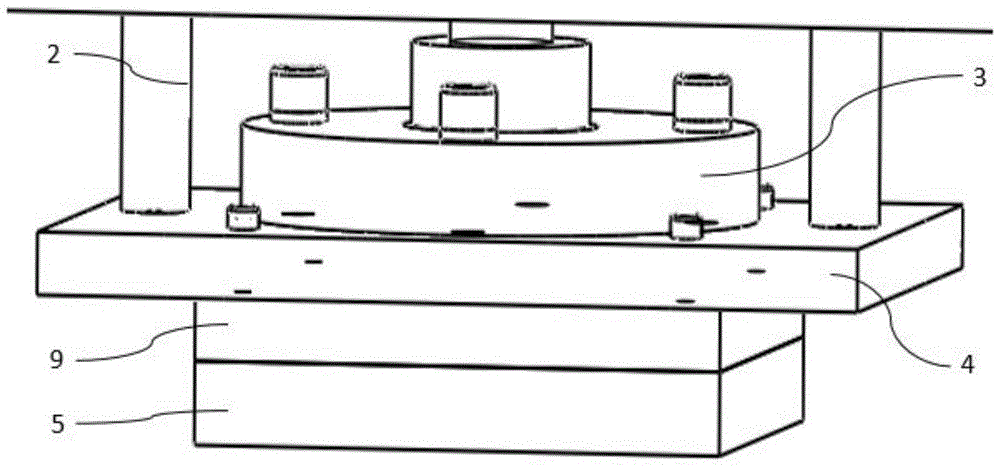

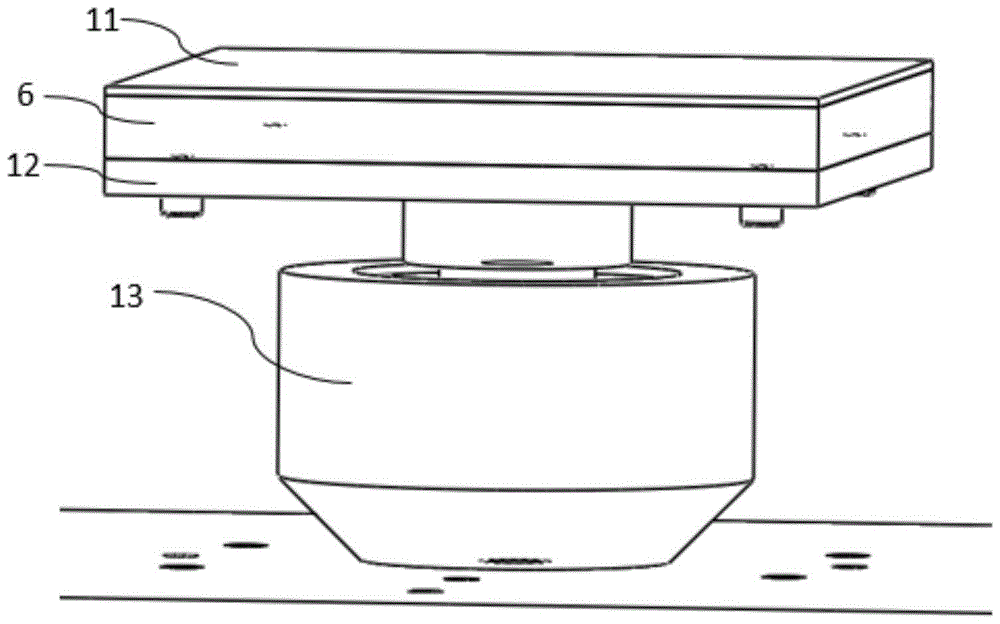

[0030] The specific real-time mode of the present invention will be described below in conjunction with the accompanying drawings:

[0031] The booster cylinder 1 is fixed on the upper plate 8, and the booster cylinder 1 is driven by a pneumatic system to make the flexible upper pressure head extend and retract;

[0032] A through hole is drilled in the center of the upper plate 8, and the diameter is 2mm larger than the piston rod of the booster cylinder 1; a through hole is machined on the left and right sides of the upper plate 8, and the through hole processing tolerance is H7, and each through hole is equipped with two flanged sliding sleeves 7 , the sliding sleeve 7 is symmetrically fixed in the through hole, and the sliding sleeve and the through hole have an interference fit;

[0033] The flexible upper pressing plate 5, the rigid upper pressing plate 9, and the guide rod connecting plate 4, which are fixed up and down together, constitute the flexible upper pressing h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com