Balloon preventing device for weft feeder of loom, especially air jet loom

A technology of air-jet loom and weft feeding, applied in looms, textiles, transportation and packaging, etc., can solve problems such as failure to obtain expected results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

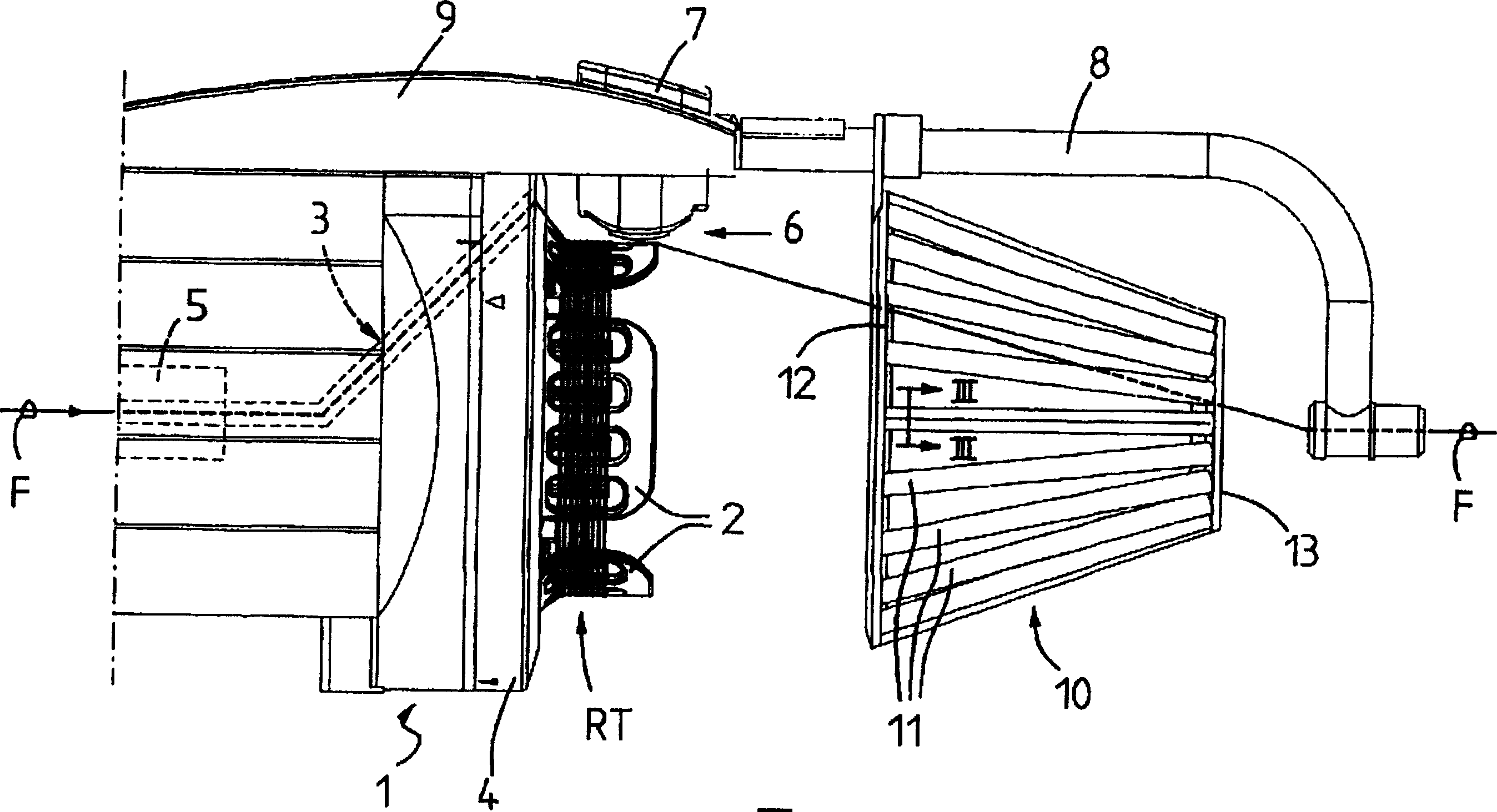

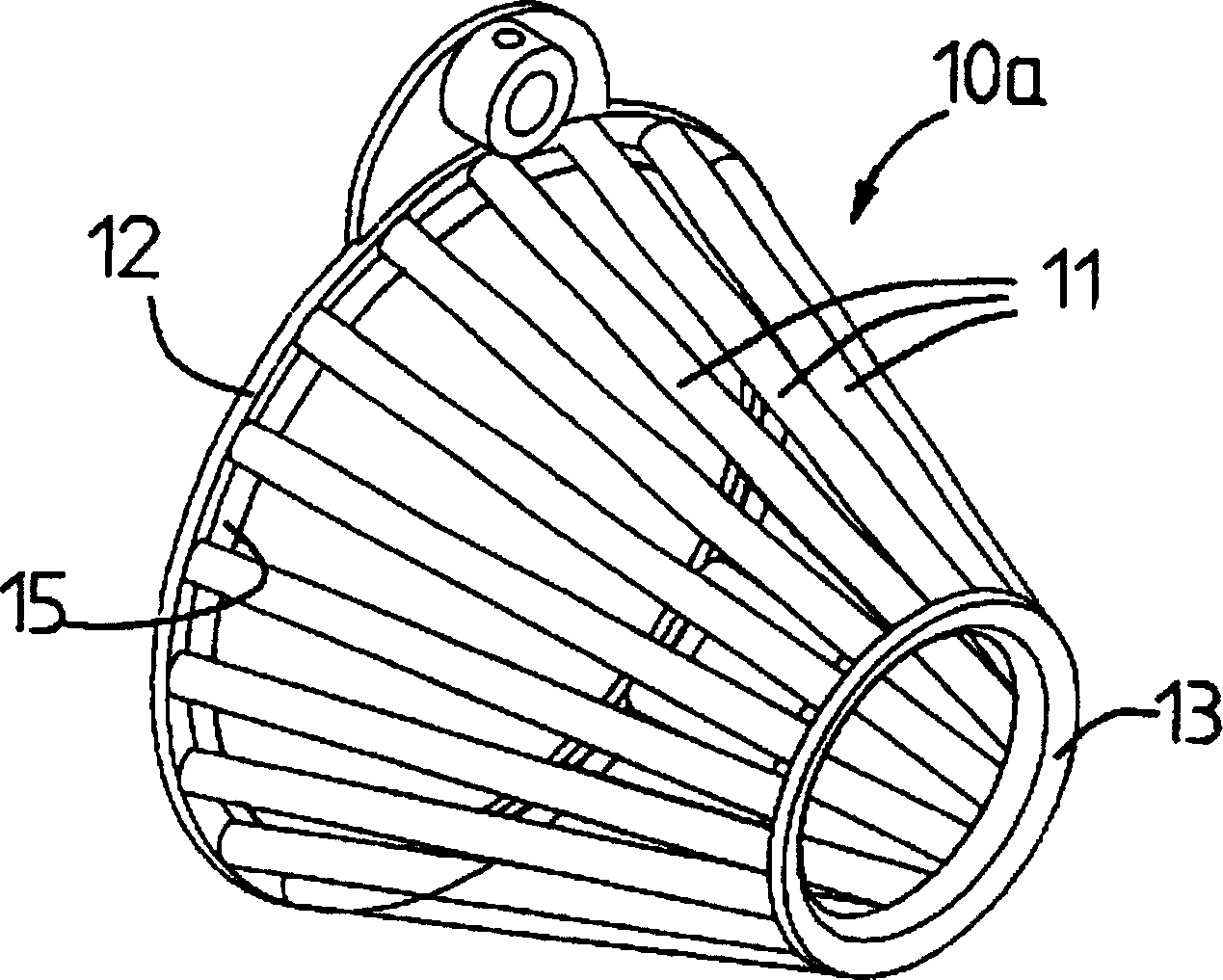

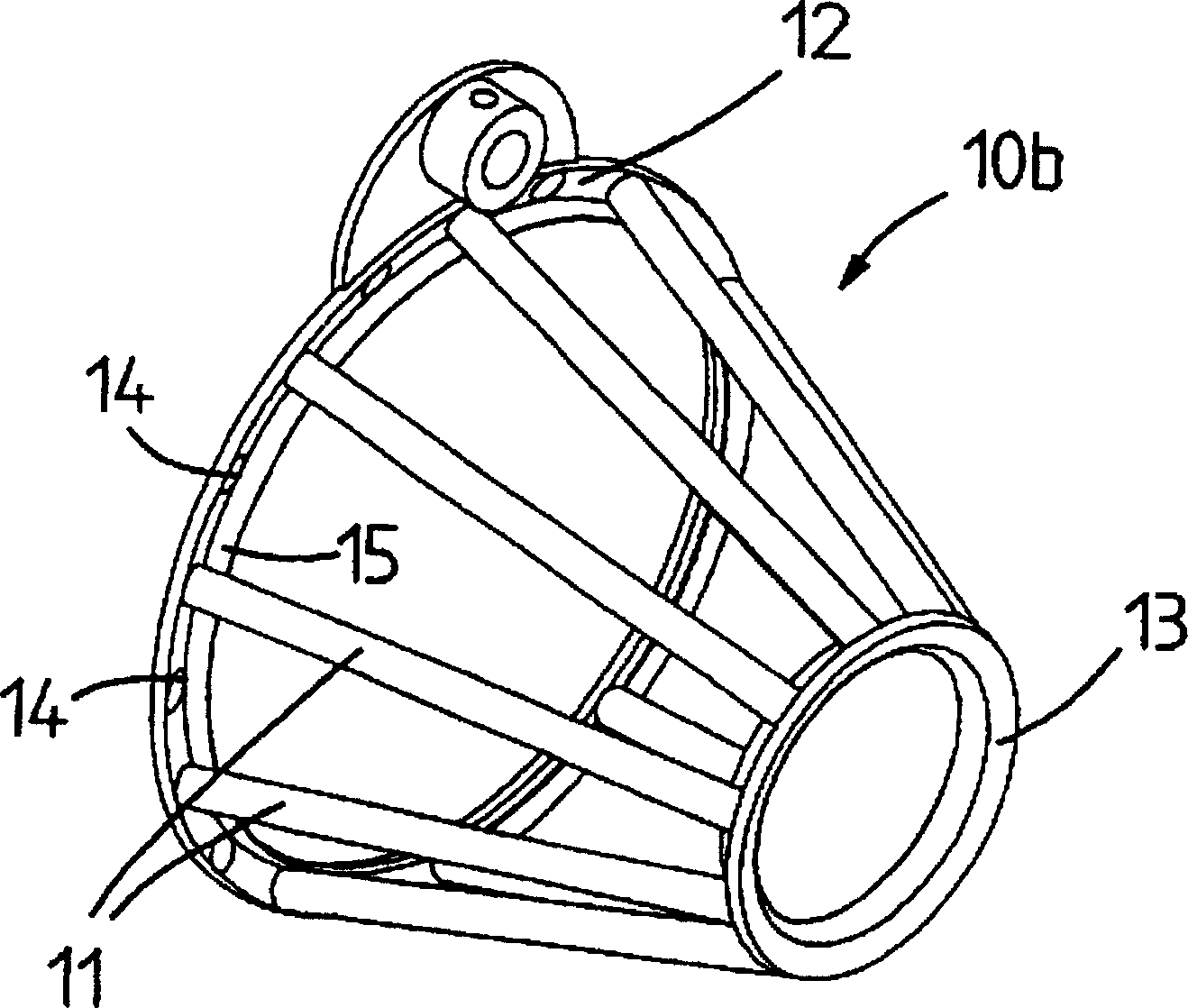

[0026] In the figures, reference numeral 1 generally designates a projected weft feeder for a jet loom, in particular an air jet loom. In the prior known technology, the weft feeder 1 comprises a fixed cylinder 2 with a variable diameter, on which a rotating arm 3 is connected to a flywheel 4 and driven by a motor 5, the rotating arm winds multiple turns of weft yarn on the cylinder to Constitute the reserve weft yarn RT, a weft yarn brake 6 used to stop the movement of the weft yarn F is connected to the cylinder 2 of the weft feeder 1, and is driven by an electromagnetic driver 7 to release the weft yarn, so that it is unwound from the cylinder 2 and is Unwinding stops when the predicted weft insertion length is reached. A microprocessor (not shown) pre-set to manage the entire system of feeding of the weft yarn F generates a signal to control the weft yarn brake 6 and an additional signal to control the motor 5, based on such control signals the progressively unwound weft y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com