Liquid crystal display with double-film transister pixel structure

A liquid crystal display, switching transistor technology, applied in the direction of transistors, instruments, optics, etc., can solve the problems of short charging time, line ripple, changes, etc., to achieve high display frequency, high resolution, and reduce the effect of feed-through voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

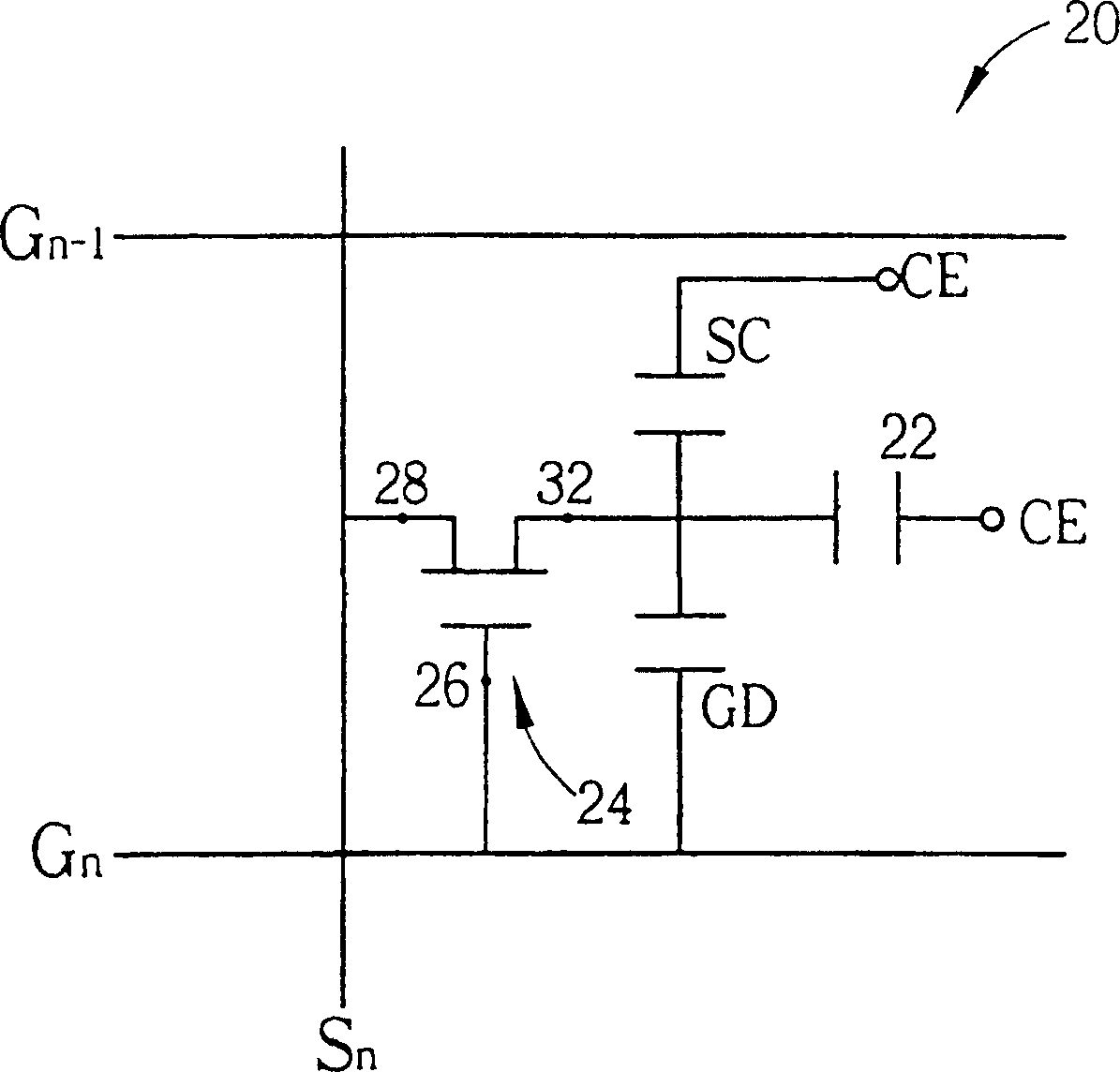

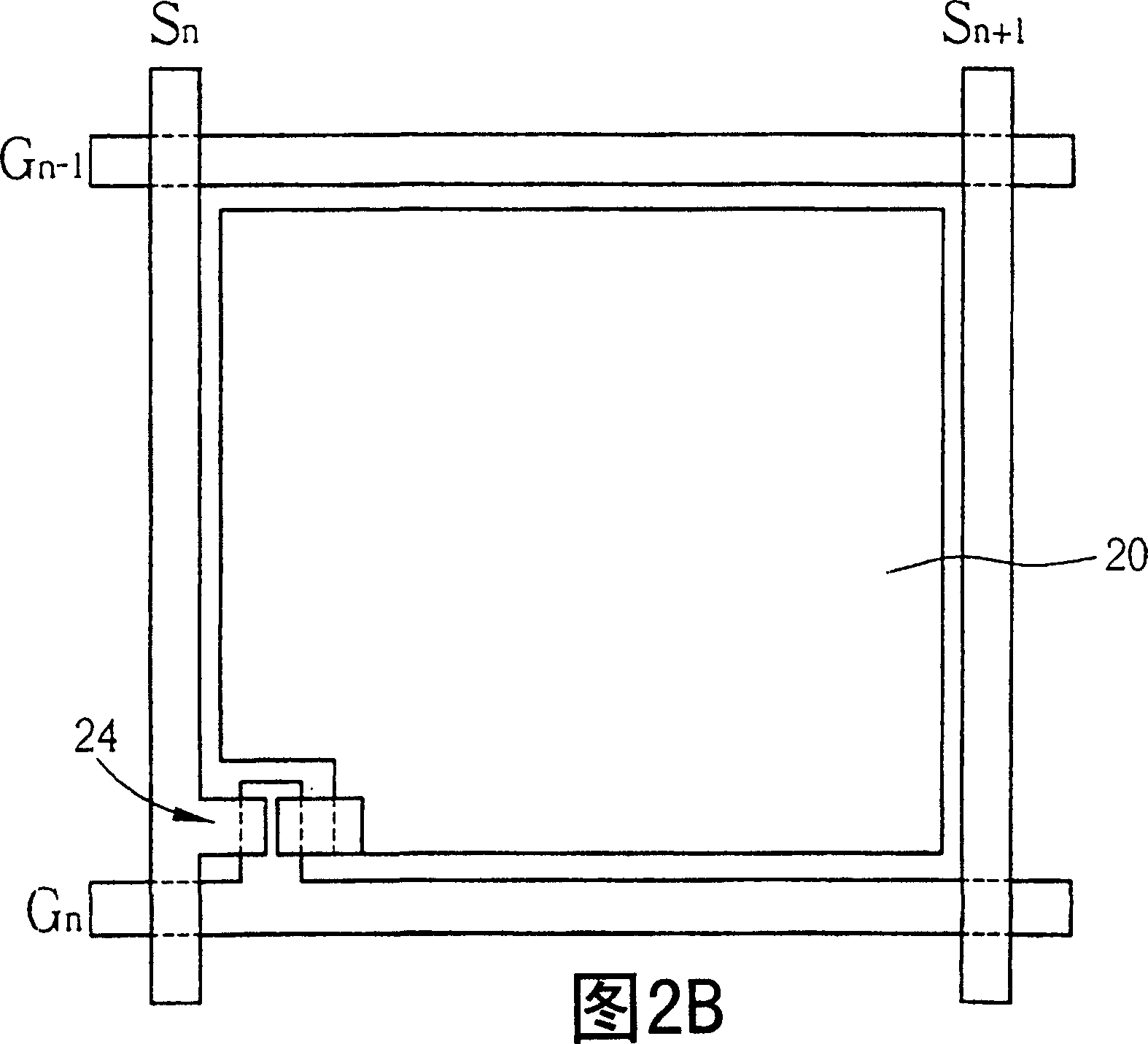

[0024] Please refer to Figure 5, Figure 5A is a schematic diagram of an equivalent circuit of each pixel 100 of the present invention, Figure 5B It is a top view of each pixel 100 of the present invention. Such as Figure 5A and Figure 5B As shown, each pixel 100 of the present invention includes a liquid crystal unit (liquid crystal unit, LC unit) 102 filled with liquid crystal molecules (liquid crystalmolecules, not shown), a pixel electrode (pixel electrode, not shown), a first A thin film transistor (first thin film transistor, first TFT) 104 and a second thin film transistor (second thin film transistor, second TFT) 106 . The liquid crystal unit 102 is electrically connected to a common counter electrode (CE), and the first thin film transistor 104 and the second thin film transistor 106 are both used as switches to control the pixel electrode (not shown). Charge. Wherein, the gate electrode 108 of the first thin film transistor 104 is electrically connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com